Vacuum ion plating Ag nano composite coating fastener and preparation method

A nanocomposite coating and vacuum ion plating technology, applied in the field of new materials, can solve problems such as poor performance, pollution performance, silver plating pollution of fasteners, etc., and achieve the goal of improving surface quality, adhesion, and corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

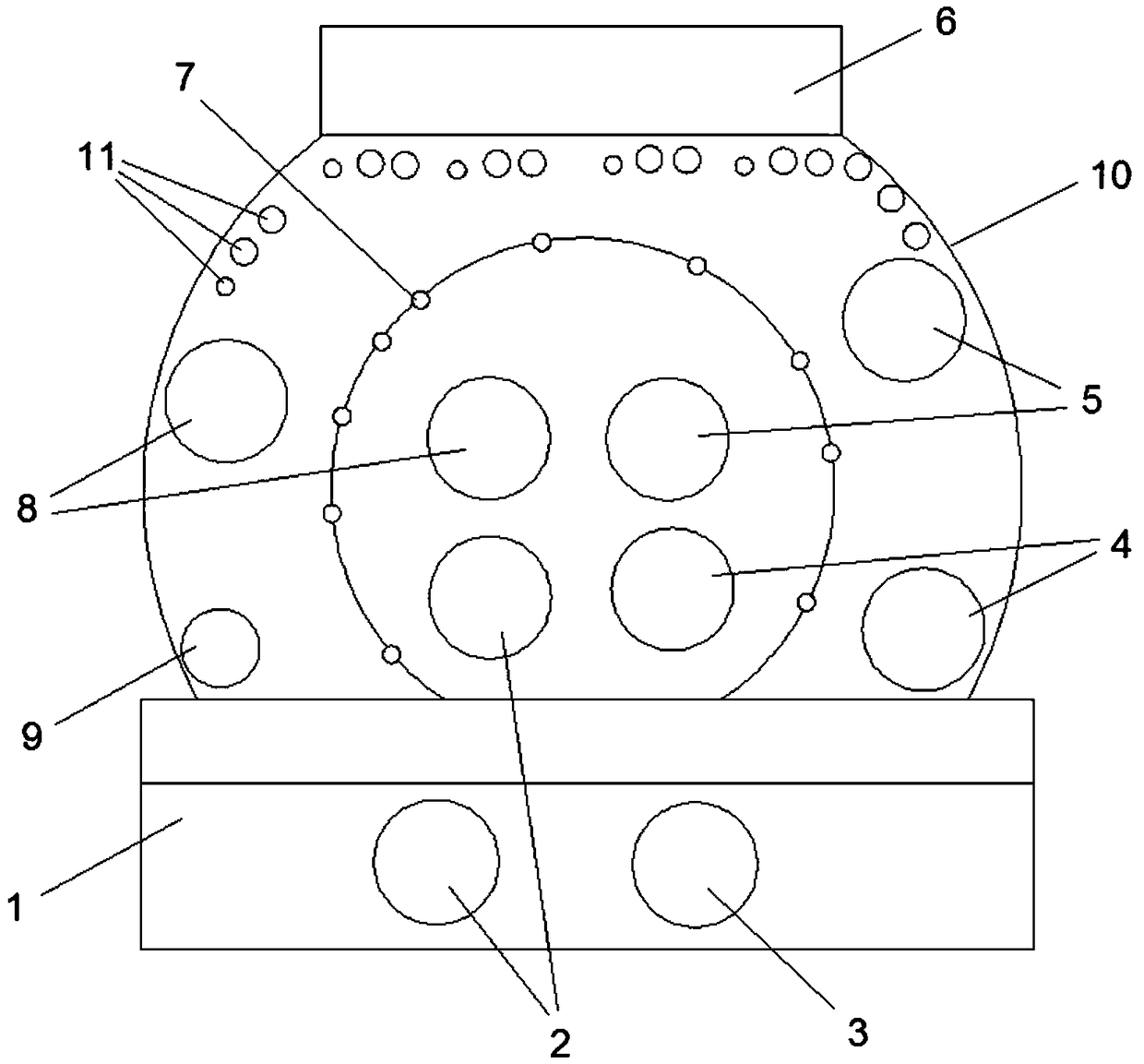

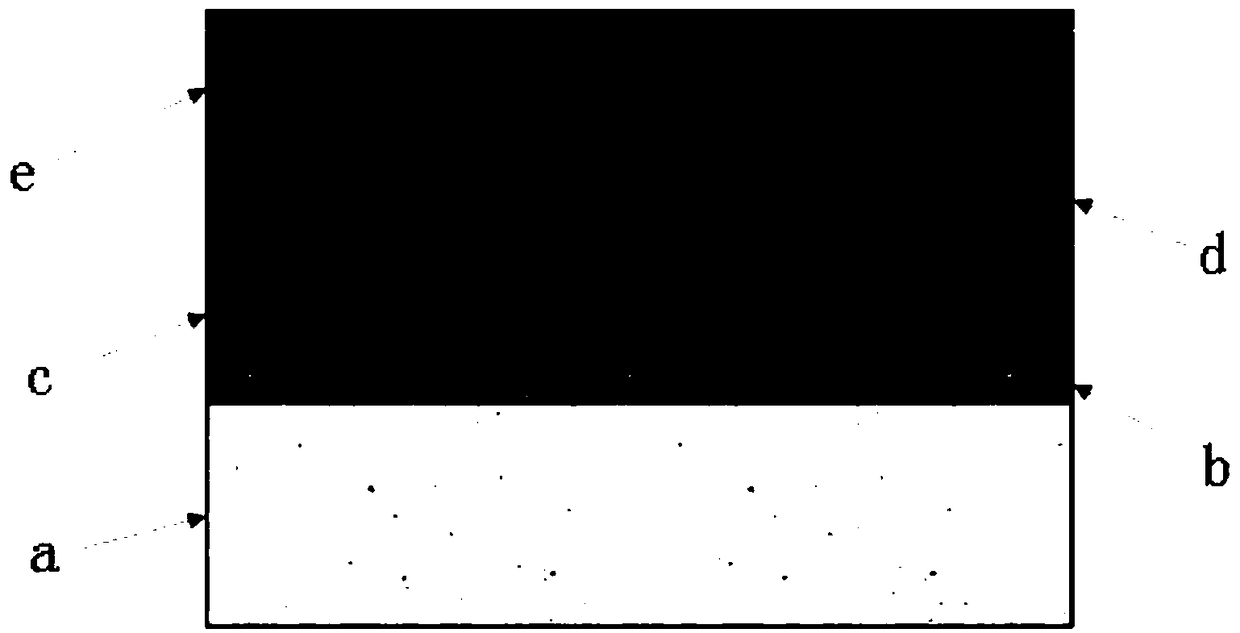

[0026] Refer to attached figure 1 and 2 , the present embodiment provides a vacuum ion-plated Ag nano-composite coating fastener, the vacuum ion-plated Ag nano-composite coating adopts a gradient layer structure, composed of a diffusion layer, a bonding layer, a transition layer and an Ag high-temperature self-lubricating composite coating constitute. The diffusion layer is 5-10 nanometers, the thickness of the bonding layer is 20-200 nanometers, the thickness of the transition layer is 100-200 nanometers, and the thickness of the high-temperature self-lubricating coating is 1-10 microns. The diffusion layer is a pure Ti diffusion layer prepared by arc ion plating with high energy bombardment, the bonding layer is a pure Ti layer prepared by ion plating with low energy, and the transition layer is Ti evaporated by arc ion plating and intermediate frequency magnetron sputtering. The Ti-Ag nano-multilayer film formed by Ag prepared under voltage conditions, the thickness of th...

Embodiment 2

[0030] Example 2: After the alloy steel fasteners are plasma etched at 100°C in an argon and hydrogen environment, the target 2 is arc-discharged in an argon environment by using an arc, and it is carried out under the conditions of 0.02Pa and -800V Preparation of nano-Ti diffusion layer; followed by medium-frequency magnetron sputtering in an argon environment to prepare a 20-nanometer Ti bonding layer on target 8 at 0.4Pa, -50V; , using intermediate frequency magnetron sputtering to target 8 and the first DC magnetron sputtering to target 4 to prepare a 100 nanometer Ti-Ag nanocomposite metal transition layer, the thickness of the single-layer Ti layer is 3 nanometers, and the thickness of the single-layer Ag layer The thickness is 5 nanometers, and the modulation cycle thickness range formed by the two coatings is 8 nanometers; after the preparation of the transition layer, at 0.4 Pa, use intermediate frequency magnetron sputtering to target 8, the first direct current magne...

Embodiment 3

[0031] Example 3: After plasma etching the alloy steel fasteners at 450°C in an argon and hydrogen environment, an arc is used to discharge the target 2 in an argon environment at 0.2Pa, -1000V Preparation of 10nm Ti diffusion layer; followed by target 8 in an argon environment to prepare a 200nm Ti bonding layer at 1Pa, -500V; after the bonding layer is prepared, use an arc to target 2 and The first direct current magnetron sputtering carries out the preparation of 200 nanometers Ti-Ag nano-composite metal transition layer to target 4, the thickness of single-layer Ti layer is 20 nanometers, the thickness of single-layer Ag layer is 20 nanometers, two kinds of coatings are formed The modulation cycle thickness range is 40 nanometers; after the preparation of the transition layer, at 1Pa, the intermediate frequency magnetron sputtering target 8, the first DC magnetron sputtering target 4 and the second DC magnetron sputtering target 5 Conduct 10 micron Ag at -250V in an argon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com