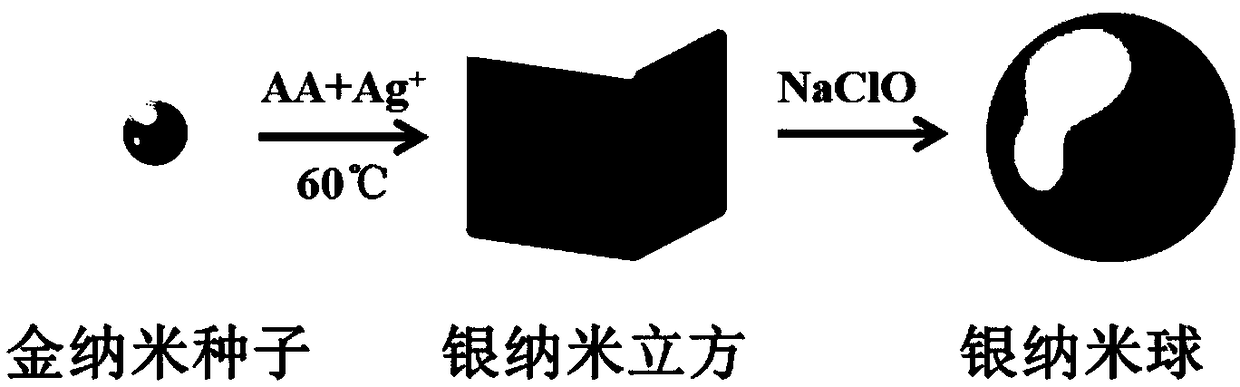

Aqueous phase preparation method for single crystal silver nanosphere

A water phase preparation, silver nanotechnology, applied in the field of nanomaterials, can solve the problems of cumbersome steps, high reaction temperature, unfavorable environmental protection, etc., and achieve the effect of safe preparation process, good stability, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) First, add 5mL of 0.5mM chloroauric acid solution to 5mL of 0.2M cetyltrimethylammonium bromide (CTAB) solution, stir slowly for 2 minutes and quickly add 0.6mL of freshly prepared hydroboration Sodium aqueous solution (10mM), after vigorously stirring for 2 minutes, gold nanoseeds with a size of about 3nm were obtained;

[0033] 2) Add 6mL of 0.5mM chloroauric acid solution to 6mL of 0.2M cetyltrimethylammonium chloride (CTAC) solution, add 4.5mL of 0.1M ascorbic acid after stirring at a slow speed for 2 minutes, and finally Add 150 μL of 3nm gold nanoseeds prepared in step 1), keep stirring for 15 minutes to obtain gold nanoseeds with a size of about 10nm, centrifuge 5.5mL of the gold nanoseed solution twice and disperse them in 1mL of water;

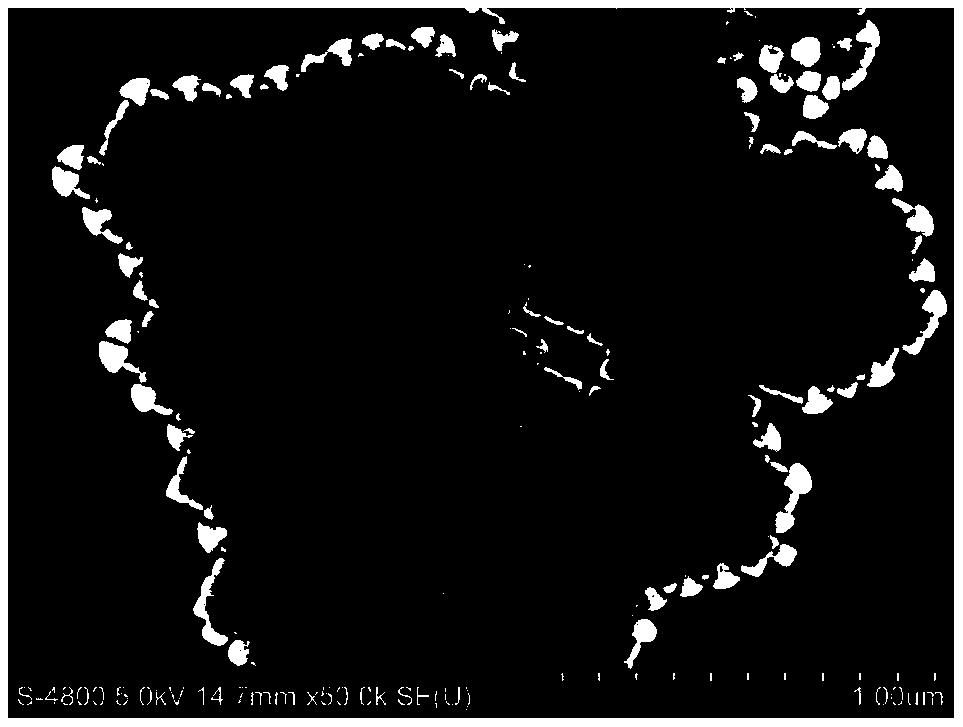

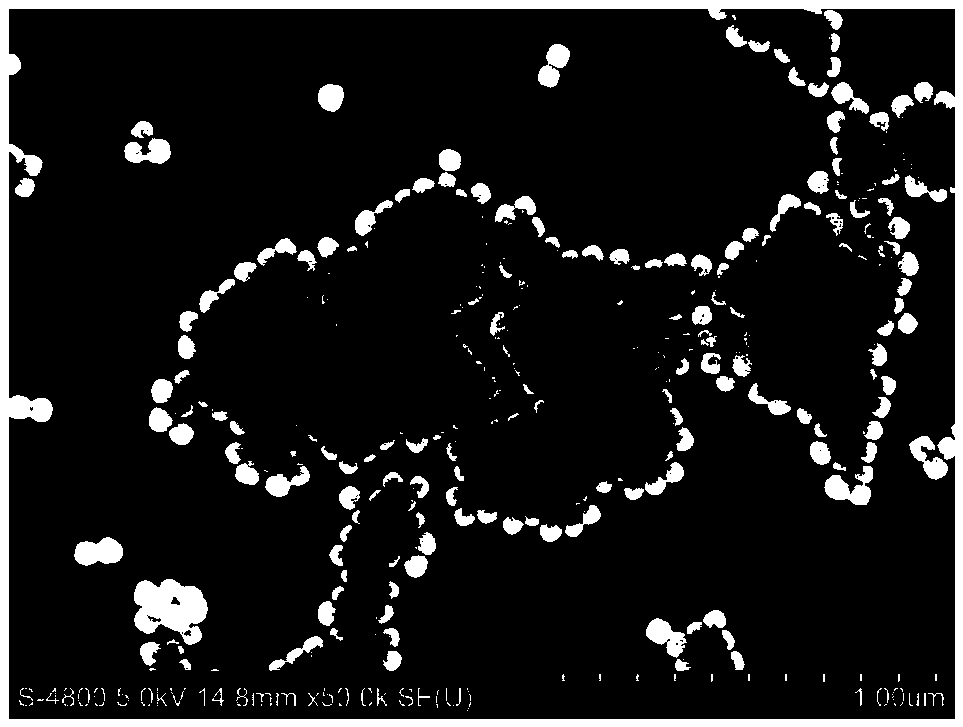

[0034] 3) Add 100 μL of the gold nanoseeds prepared in step 2) to 40 mL of 20 mM CTAC solution, stir in a water bath at 60°C for 15 minutes, then add 100 μL of 0.1 M silver nitrate solution, stir for 15 minutes, then add 1 m...

Embodiment 2

[0039] 1) First, add 5mL of 0.5mM chloroauric acid solution to 5mL of 0.2M cetyltrimethylammonium bromide (CTAB) solution, stir slowly for 2 minutes and quickly add 0.6mL of freshly prepared hydroboration Sodium aqueous solution (10mM), after vigorously stirring for 2 minutes, gold nanoseeds with a size of about 3nm were obtained;

[0040] 2) Add 6mL of 0.5mM chloroauric acid solution to 6mL of 0.2M cetyltrimethylammonium chloride (CTAC) solution, add 4.5mL of 0.1M ascorbic acid after stirring at a slow speed for 2 minutes, and finally Add 150 μL of 3nm gold nanoseeds prepared in step 1), keep stirring for 15 minutes to obtain gold nanoseeds with a size of about 10nm, centrifuge 5.5mL of the gold nanoseed solution twice and disperse them in 1mL of water;

[0041] 3) Add 100 μL of the gold nanoseeds prepared in step 2) to 40 mL of 20 mM CTAC solution, stir in a water bath at 60°C for 15 minutes, then add 100 μL of 0.1 M silver nitrate solution, stir for 15 minutes, then add 1 m...

Embodiment 3

[0046] 1) First, add 5mL of 0.5mM chloroauric acid solution to 5mL of 0.2M cetyltrimethylammonium bromide (CTAB) solution, stir slowly for 2 minutes and quickly add 0.6mL of freshly prepared hydroboration Sodium aqueous solution (10mM), after vigorously stirring for 2 minutes, gold nanoseeds with a size of about 3nm were obtained;

[0047]2) Add 6mL of 0.5mM chloroauric acid solution to 6mL of 0.2M cetyltrimethylammonium chloride (CTAC) solution, add 4.5mL of 0.1M ascorbic acid after stirring at a slow speed for 2 minutes, and finally Add 150 μm of the 3nm gold nanoseeds prepared in step 1), keep stirring for 15 minutes to obtain gold nanoseeds with a size of about 10nm, and 5.5mL of the gold nanoseed solution is centrifuged twice and dispersed in 1mL of water;

[0048] 3) Add 50 μL of the gold nanoseeds prepared in step 2) to 40 mL of 20 mM CTAC solution, stir in a water bath at 60°C for 15 minutes, then add 100 μL of 0.1M silver nitrate solution, stir for 15 minutes, then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com