Reusable modified porous ceramic material based sewage treatment method

A sewage treatment method and porous ceramic technology, which are applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult heavy metal sewage treatment, high treatment cost, and low treatment efficiency. , to achieve good treatment effect, improve adsorption treatment efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

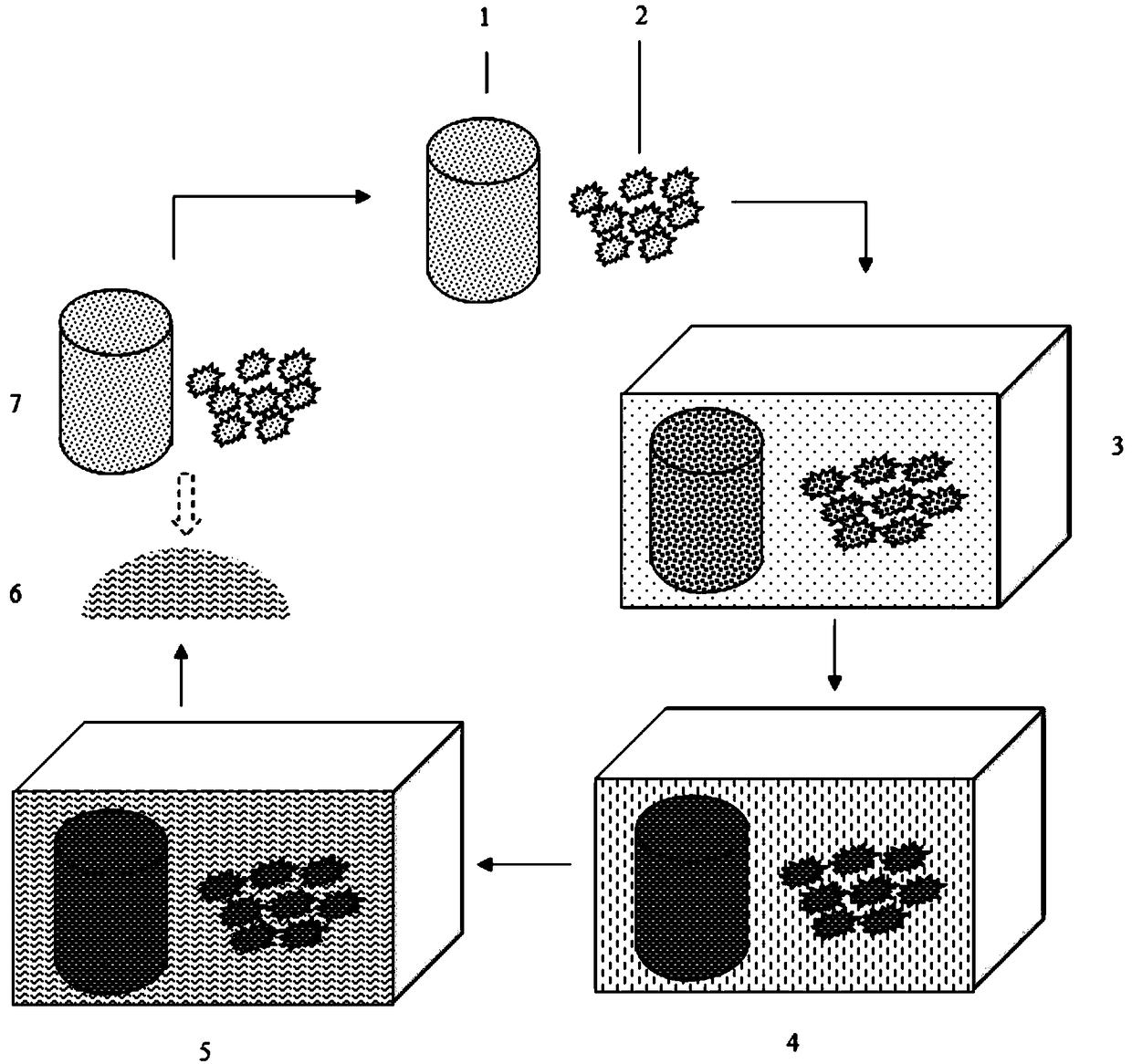

Image

Examples

Embodiment 1

[0031] Implementation example 1, using this patented technology to carry out the treatment of chromium-containing sewage.

[0032] A kind of industrial wastewater, in which the chromium content is about 10mg / L, mainly exists in the form of dichromate ion, the total amount is 10 tons, and the chromium content is about 100g. Select 110kg of porous ceramics made of corundum, with an open porosity of 75%, resistant to strong acid corrosion, in the form of particles with an average diameter of about 5 mm, and washed for later use. Prepare 100 L of sulfuric acid solution with a concentration of 2.6 mol / L, and dissolve 20 kg of starch and 10 kg of dextrin in the aforementioned sulfuric acid solution to form a porous ceramic modification solution. Soak the prepared granular porous ceramics in the aforementioned modification solution, maintain the water temperature of the solution at 65° C., and keep stirring to modify the porous ceramics for 80 minutes. Then take out the modified por...

Embodiment 2

[0033] Implementation example 2, using this patented technology to carry out the treatment of nickel-containing wastewater.

[0034] A kind of industrial wastewater, the nickel content of which is about 20mg / L, mainly exists in the form of nickel ions, and the total amount is 1 ton, so the nickel content is about 20g. Select 22kg of porous ceramics made of corundum and cordierite, with an open porosity of 70%, resistant to strong alkali corrosion, in the shape of a ring with a diameter of about 3 cm, and wash it for later use. Configure 20 L of sulfuric acid solution with a concentration of 3.0 mol / L, and dissolve 2 kg of dextrin, 2 kg of fish skin gelatin, and 2 kg of chitosan gel in the aforementioned sulfuric acid solution to form a porous ceramic modification solution. Soak the prepared ring-shaped porous ceramics in the aforementioned modification solution, keep the water temperature of the solution at 60° C., and keep stirring to carry out the modification treatment of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com