A kind of treatment method of catalyst production wastewater

A technology for producing wastewater and treatment methods, applied in natural water body treatment, multi-stage water treatment, chemical instruments and methods, etc., can solve the problems of only obtaining mixed salt crystals, high cost and low cost of wastewater treatment, and reduce treatment costs. Cost, energy saving, effect of improving evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

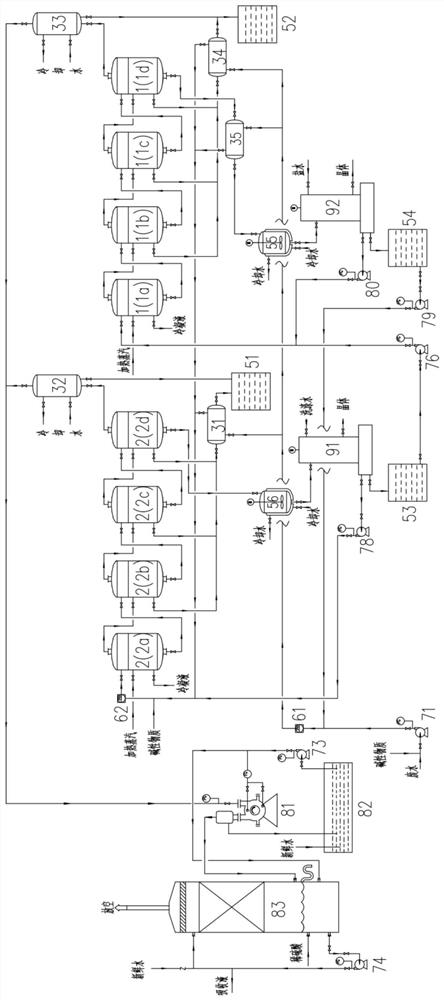

[0129] Such as figure 1 As shown, the waste water (containing NaCl 48g / L, Na 2 SO 4 90g / L, NH 4 Cl 47g / L, (NH 4 ) 2 SO 4 89.6g / L, pH 6.8) with a feed rate of 5m 3 The speed of / h is sent into the pipeline of the treatment system, mixed with the second mother liquor to obtain the waste water to be treated (the SO contained therein 4 2- and Cl - The molar ratio is 1:2.404), and the pH value after mixing is monitored by the first pH value measuring device 61 (pH meter) in the pipeline sent to the first heat exchange device 31 (titanium alloy plate heat exchanger) (measured value is 9.2), a part (3m 3 / h) into the first heat exchange device 31, and carry out the first heat exchange with the recovered first ammonia-containing steam condensate to raise the temperature of the waste water to be treated to 102 ° C, and the other part (1m 3 / h) into the fourth heat exchange device 34, and carry out the first heat exchange with the recovered second ammonia-containing steam co...

Embodiment 2

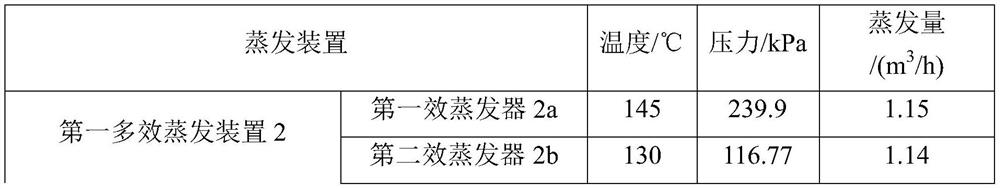

[0141] Carry out the treatment of waste water according to the method for embodiment 1, difference is: to containing NaCl 109g / L, NaCl 2 SO 4 105g / L, NH 4 Cl 23g / L, (NH 4 ) 2 SO 4 22.5g / L, pH 6.3 wastewater, the SO contained in the wastewater to be treated 4 2- and Cl - The molar ratio is 1:4.37. The temperature of the waste water to be treated after heat exchange through the first heat exchange device 31 , the fourth heat exchange device 34 and the fifth heat exchange device 35 is 108°C. The evaporation conditions of the first multiple-effect evaporator 2 and the second multiple-effect evaporator are shown in Table 3 below. The temperature of low temperature treatment is 25°C, and the residence time is 58min.

[0142] Table 2

[0143]

[0144] The first solid-liquid separation device 91 obtains 750.45 kg of sodium sulfate crystallization filter cake with water content of 14 mass % per hour, finally obtains sodium sulfate 645.39 kg (purity is 99.6% by weight) pe...

Embodiment 3

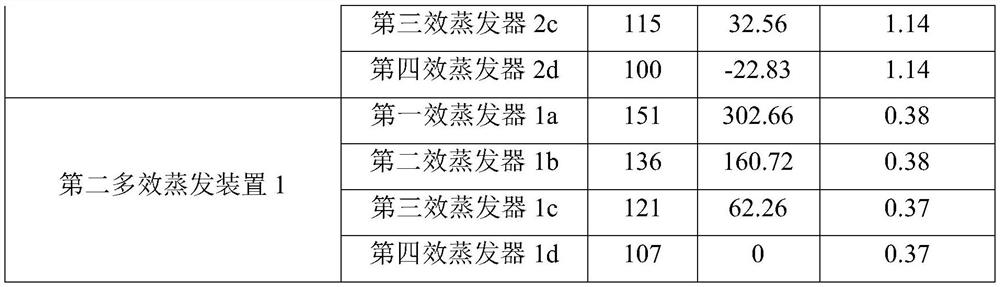

[0148] Carry out the treatment of waste water according to the method for embodiment 1, difference is: to containing NaCl 162g / L, NaCl 2 SO 4 69g / L, NH 4 Cl 30g / L, (NH 4 ) 2 SO 4 13g / L, pH 6.6 wastewater, the SO contained in the wastewater to be treated 4 2- and Cl - The molar ratio is 1:7.198. The temperature of the wastewater to be treated after heat exchange by the first heat exchange device 31 , the fourth heat exchange device 34 and the fifth heat exchange device 35 is 110°C. The evaporation conditions of the first multiple-effect evaporator 2 and the second multiple-effect evaporator are shown in Table 3 below. The temperature of low temperature treatment is 30°C, and the residence time is 55min.

[0149] table 3

[0150]

[0151] The first solid-liquid separation device 91 obtains 485.29 kg of sodium sulfate crystallization filter cake containing 15 mass % of water per hour, finally obtains 412.50 kg of sodium sulfate per hour (purity is 99.4% by weight);...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com