Organosilane emulsion type gypsum waterproofing agent and preparation method thereof

A technology of organosilane and waterproofing agent, which is applied in the field of organosilane emulsion type gypsum waterproofing agent and its preparation, which can solve the problems of strong influence of gypsum, strong alkalinity, high content of sodium oxide, etc., and achieve excellent water repelling effect and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

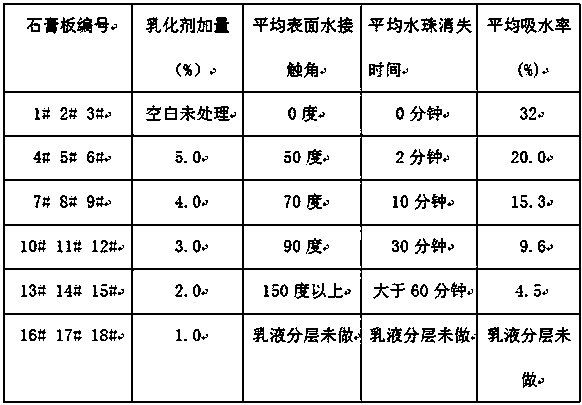

Examples

preparation example Construction

[0015] A preparation method of organosilane emulsion type gypsum waterproofing agent, the steps are:

[0016] In a 1000ml plastic cylinder, add methyltriethoxysilane and mixed alkyl alcohol polyoxyethylene ether emulsifier, in a high-speed shear homogenizer, the speed is 5000-10000rpm, slowly add water, when the water is added, the oil and water are mixed The liquid becomes thicker, and with the addition of water, the emulsion slowly becomes thinner. After adding water, it is then sheared at high speed for 5 minutes to obtain a water repellent emulsion with a mass percentage of 30%.

[0017] The HLB value of the mixed alkyl alcohol polyoxyethylene ether is 11.0.

Embodiment 1

[0018] Example 1: In a 1000ml plastic cylinder, 150 grams of methyltriethoxysilane was added, and a total of 6 grams of alkyl alcohol polyoxyethylene ether emulsifier (the HLB value of the mixed alcohol ether was 11.0) was mixed. In the carburetor, the speed is 5000-10000rpm, slowly add 350 grams of water, the oil-water mixture becomes thicker when water is added, and the emulsion slowly becomes thinner with the addition of water, after adding water, and then high-speed shearing for 5 minutes, to obtain 500 grams of 30% oil-in-water emulsion is tested by a laser particle size tester. The particle size is within 0-3um, the average particle size is about 1um, and the centrifugal stability test is qualified. There is no change in the heat stability test at 40°C for 28 days, and there is no change in the 5°C low temperature room stability test for 28 days. Adding 5% calcium chloride solution produced no precipitation.

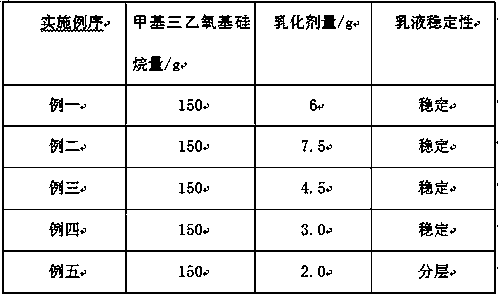

[0019] Embodiment two to five, change the amount of emulsifi...

Embodiment 11

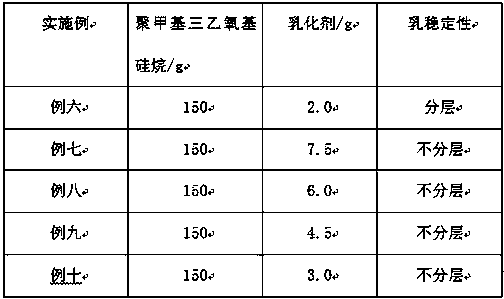

[0031] Embodiment 11: Change the order of addition. In the above embodiments 1 to 10, the silane and emulsifier are first mixed together to form an oil phase, and water is slowly added to the oil phase under high-speed shearing to form an oil-in-water emulsion. If the emulsifier is mixed with water first, the oil-in-water emulsion can also be obtained by slowly adding the silane oil phase to the water phase under high shear. The stability is the same as the emulsion obtained by adding water to oil. Similarly, when the amount of emulsifier is less than 2%, a stable emulsion cannot be obtained, and when the oil phase is added to water, even if the HLB value of the emulsifier is lower than 10, an oil-in-water emulsion can be obtained. If water is added to the oil phase, such as HLB value ≤ 10, only water-in-oil emulsion can be obtained, which is not well dispersed in water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com