Feed composition, preparation method of feed composition and apparatus for preparing feed composition

A feed composition and feed technology, applied in the field of feed, can solve the problems of being unfavorable to large-scale breeding environment, low palatability of dry-based materials, and unfavorable to the growth of fattening pigs, and achieve easy absorption by animals, large workload, and low resource utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

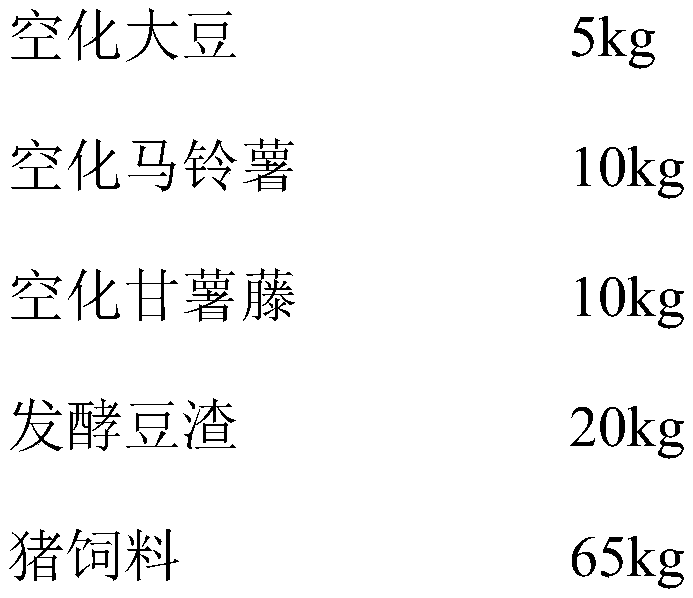

[0077] A feed composition comprising the following components in parts by weight:

[0078]

[0079] Preparation:

[0080] (1) Soak the raw grain for 16 hours according to the weight ratio of feed to water 1:3, and after coarse filtration to remove the water, then add it to the cavitation tank according to the weight ratio of feed to water 1:2 for cavitation treatment;

[0081] (2) Potatoes and sweet potato vines are cleaned, chopped, and added into a cavitation tank according to a feed-to-water weight ratio of 1:1 for cavitation treatment, and the gained cavitation feed is put into an insulated storage tank for subsequent use;

[0082] (3) Dissolve Lactobacillus plantarum, Bacillus subtilis and Saccharomyces cerevisiae in water at a volume ratio of 1:50, add brown sugar with a weight ratio of 2%, and mix the activated bacterial liquid, water, molasses and fermentation-promoting additives Evenly, add the mixed bacterial liquid into the raw materials of the fermentation tank...

Embodiment 2

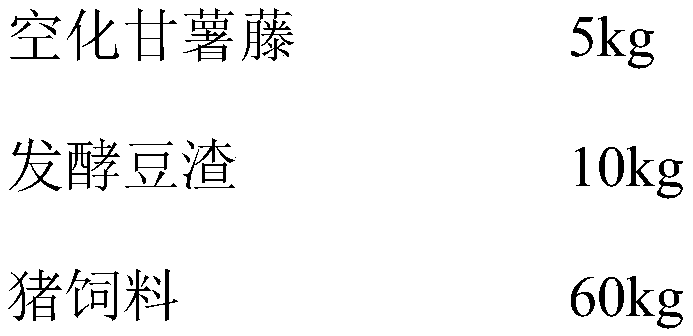

[0090] A feed composition comprising the following components in parts by weight:

[0091]

[0092]

[0093] Preparation:

[0094] (1) Potatoes and sweet potato vines are cleaned, chopped, and added into a cavitation tank for cavitation treatment according to a feed-to-water weight ratio of 1:0.5, and the gained cavitation feed is put into an insulated storage tank for subsequent use;

[0095] (2) Dissolve Lactobacillus plantarum, Bacillus subtilis and Saccharomyces cerevisiae in water at a volume ratio of 1:50, add brown sugar with a weight ratio of 2%, and mix the activated bacterial liquid, water, molasses and fermentation-promoting additives Evenly, add the mixed bacterial liquid to the raw materials of the fermentation tank, stir for 2 minutes, cover the tank lid, and let it stand for fermentation for 3 days. The fermentation temperature is controlled at 40°C, and the fermentation materials are flipped forward and reverse every 4 hours;

[0096] (3) Mix the cavitat...

Embodiment 3

[0098] A feed composition comprising the following components in parts by weight:

[0099]

[0100] Preparation:

[0101] (1) Potatoes and sweet potato vines are cleaned, chopped, and added into a cavitation tank according to a feed-to-water weight ratio of 1:0.6 for cavitation treatment, and the gained cavitation feed is put into an insulated storage tank for subsequent use;

[0102] (2) Dissolve Lactobacillus plantarum, Bacillus subtilis and Saccharomyces cerevisiae in water at a volume ratio of 1:50, add brown sugar with a weight ratio of 2%, and mix the activated bacterial liquid, water, molasses and fermentation-promoting additives Evenly, add the mixed bacterial liquid into the raw materials of the fermentation tank, stir for 5 minutes, cover the tank lid, and let it stand for fermentation for 4 days. The fermentation temperature is controlled at 35°C, and the fermentation materials are turned forward and backward every 8 hours;

[0103] (3) Mix the cavitation feed, fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com