Preparation method and application of carbon loaded bismuth nanoparticle catalyst

A particle catalyst and bismuth nanotechnology, which is applied in the preparation and application of carbon dioxide electrochemical reduction catalysts, can solve problems such as rare research reports, and achieve the effects of simple preparation method, convenient operation, and improved electrochemical surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

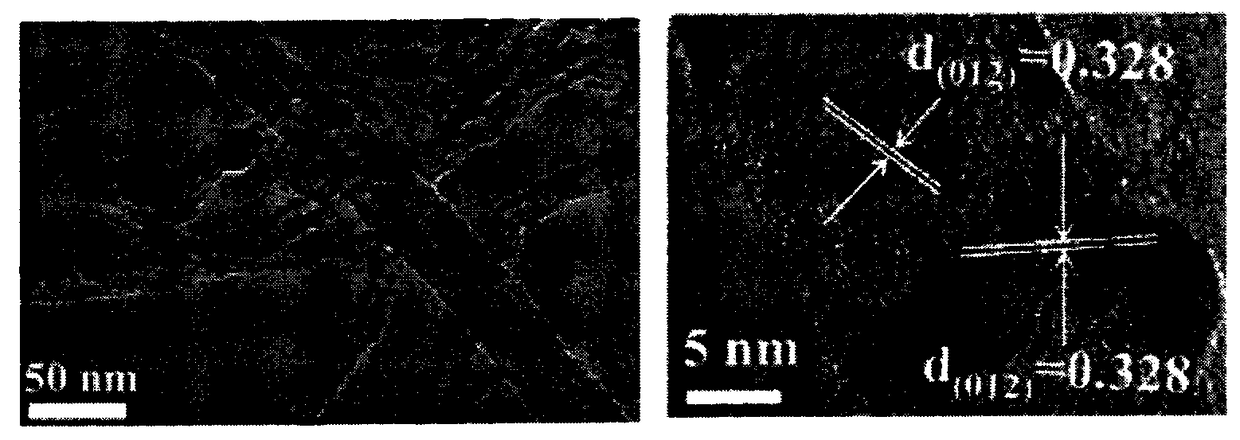

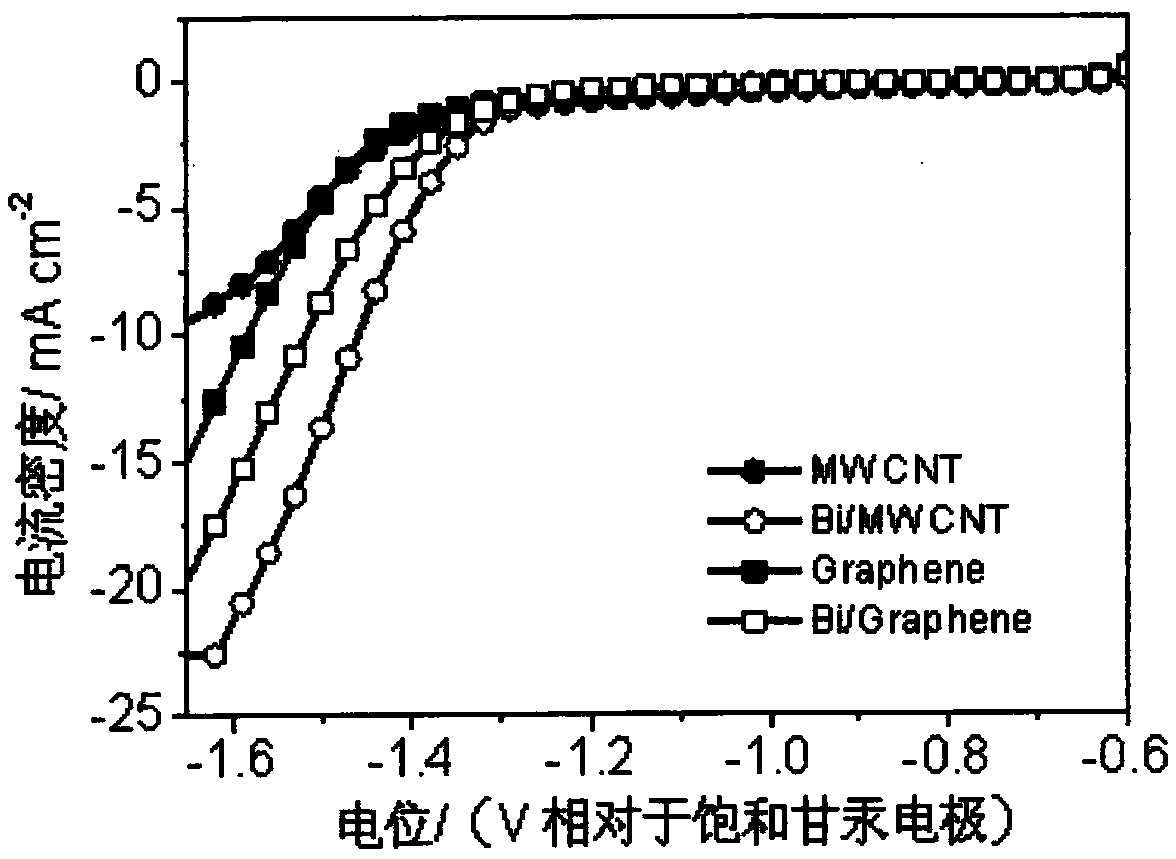

[0026] This embodiment provides a carbon-supported bismuth nanoparticle catalyst, which is synthesized by an aqueous solution chemical reduction method, and its raw materials include carbon materials and metal elemental Bi. The metal elemental Bi is nanoparticles with a particle diameter of 2-5 nm; the Bi nanoparticles are loaded on the carbon material.

[0027] The preparation method of the carbon-supported bismuth nanoparticle catalyst is as follows: Weigh 2.5 mmol of bismuth nitrate pentahydrate and add it to a beaker, add 10 mL of deionized water and 0.5 mL of concentrated nitric acid, and stir magnetically for 2 hours to obtain a 0.25 M bismuth nitrate solution; Take 2mL of 0.25M bismuth nitrate solution and dissolve it in 200mL deionized water, add 4mM trisodium citrate, stir for 30min to obtain a catalyst precursor solution, add 0.1g of -COOH functionalized multi-walled carbon nanotubes, stir for 30min, After ultrasonication for 30 min, 60 mL of 0.1 M sodium borohydride...

Embodiment 2

[0032] This embodiment provides a carbon-supported bismuth nanoparticle catalyst, which is synthesized by an aqueous solution chemical reduction method, and its raw materials include carbon materials and metal elemental Bi. The metal elemental Bi is nanoparticles with a particle diameter of 2-5 nm; the Bi nanoparticles are loaded on the carbon material.

[0033]The preparation method of the carbon-supported bismuth nanoparticle catalyst is as follows: Weigh 2.5 mmol of bismuth nitrate pentahydrate and add it to a beaker, add 10 mL of deionized water and 0.5 mL of concentrated nitric acid, and stir magnetically for 2 hours to obtain a 0.25 M bismuth nitrate solution; Take 2mL of 0.25M bismuth nitrate solution and dissolve it in 200mL deionized water, add 4mM trisodium citrate, stir for 30min to obtain a catalyst precursor solution, add 0.1g of graphene, stir for 30min, after ultrasonication for 30min, add dropwise 60mL of 0.1 M's sodium borohydride reduction solution was stirre...

Embodiment 3

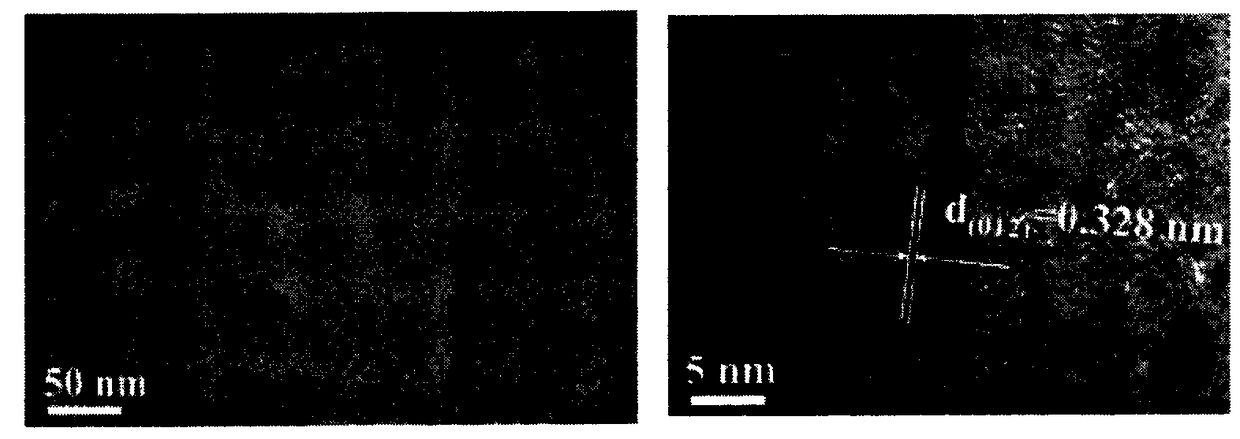

[0038] This embodiment provides a carbon-supported bismuth nanoparticle catalyst, which is synthesized by an aqueous solution chemical reduction method, and its raw materials include carbon materials and metal elemental Bi. The metal elemental Bi is nanoparticles with a particle diameter of 2-5 nm; the Bi nanoparticles are loaded on the carbon material.

[0039] The preparation method of the carbon-supported bismuth nanoparticle catalyst is as follows: Weigh 2.5 mmol of bismuth nitrate pentahydrate and add it to a beaker, add 10 mL of deionized water and 0.5 mL of concentrated nitric acid, and stir magnetically for 2 hours to obtain a 0.25 M bismuth nitrate solution; Dissolve 2mL of 0.25M bismuth nitrate solution in 200mL of deionized water, add 2mM trisodium citrate, and stir for 30min to obtain a catalyst precursor solution, add 0.1g of -COOH functionalized multi-walled carbon nanotubes, and stir for 30min , after ultrasonication for 30min, 60mL of 0.1M sodium borohydride re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com