Preparation method of thermostable and high-toughness ceramic glaze

A ceramic glaze, high toughness technology, used in clay products, applications, household appliances, etc., can solve the problems of poor thermal stability and insufficient toughness, achieve good thermal stability, improve toughness and thermal stability, and enhance adsorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

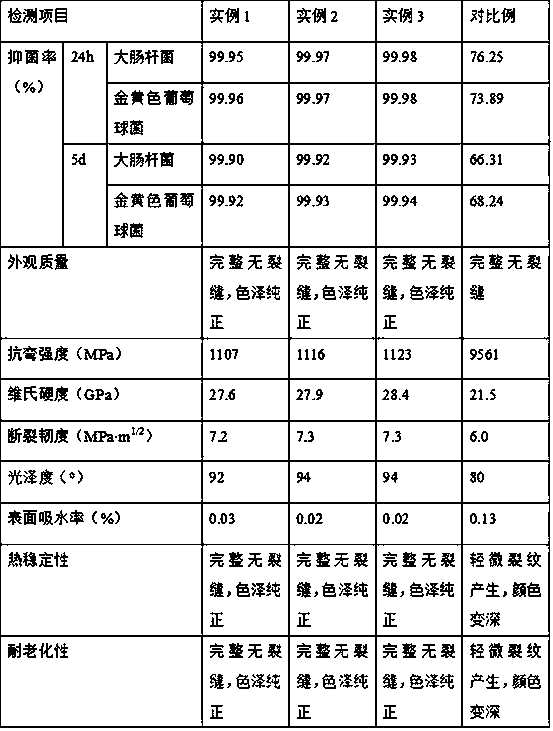

Examples

example 1

[0025] In parts by weight, weigh 1 part of aluminum nitrate nonahydrate crystals, 3 parts of ammonium bicarbonate powder and 40 parts of deionized water into a beaker, mix at a speed of 300r / min for 15min, and obtain a mixed solution after stirring. Put the liquid into the separatory funnel, pour 5 times the mass of the mixed solution into the flask into a 25% ammonium bicarbonate solution, open the separatory funnel, drop the mixed solution in the separatory funnel into the flask, and add 10mL / After the titration, the reaction solid was obtained by suction filtration, and the reaction solid was washed with absolute ethanol and distilled water for 3 times. After washing, it was placed in a muffle furnace, heated to 105°C, dried for 6 hours, and then heated up after drying. to 500°C, calcined at high temperature for 30 minutes to obtain the reaction product, put the reaction product into a pulverizer to pulverize, pass through a 400-mesh sieve to obtain the ground product, and ...

example 2

[0027]In parts by weight, weigh 2 parts of aluminum nitrate nonahydrate crystals, 4 parts of ammonium bicarbonate powder and 43 parts of deionized water and put them into a beaker, mix them at a speed of 325r / min for 17min, and obtain a mixed solution after stirring. Put the liquid into the separatory funnel, pour 5 times the mass fraction of the mixed solution into the flask into an ammonium bicarbonate solution with a mass fraction of 27%, open the separatory funnel, drop the mixed solution in the separatory funnel into the flask, and add 15mL / After the titration, the reaction solid was obtained by suction filtration, and the reaction solid was washed with absolute ethanol and distilled water for 4 times. After washing, it was placed in a muffle furnace, heated to 107°C, dried for 7 hours, and then heated up after drying. to 510°C, calcined at high temperature for 35 minutes to obtain the reaction product, put the reaction product into a pulverizer to pulverize, pass through...

example 3

[0029] In parts by weight, weigh 3 parts of aluminum nitrate nonahydrate crystals, 6 parts of ammonium bicarbonate powder and 45 parts of deionized water into a beaker, mix at a speed of 350r / min for 20min, and obtain a mixed solution after stirring. Put the solution into the separating funnel, pour 6 times the mass of the mixed solution into the flask, and pour 30% ammonium bicarbonate solution, open the separating funnel, drop the mixed solution in the separating funnel into the flask, and distill the mixed solution at 20mL / After the titration, the reaction solid was obtained by suction filtration, and the reaction solid was washed with absolute ethanol and distilled water for 5 times in sequence. After washing, it was placed in a muffle furnace, heated to 110°C, dried for 8 hours, and then heated up after drying. to 520°C, calcined at high temperature for 40 minutes to obtain the reaction product, put the reaction product into a pulverizer to pulverize, pass through a 400-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com