Bathroom wood-based composite material and preparation method thereof

A composite material and wood technology, applied in the field of wood composite materials for bathroom and its preparation, can solve the problems that physical and chemical properties cannot meet, can not meet design requirements, single shape and color, etc. The effect of photo-oxidative degradation and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

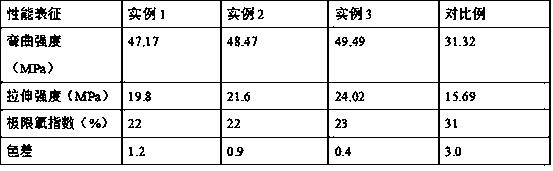

Examples

example 1

[0026]Take 1g of silane coupling agent KH-550 and 1g of titanate coupling agent TCA201, add it to 40g of absolute ethanol, stir at 300r / min at 40°C for 1h to obtain the alcoholysis solution of the composite coupling agent, take 1g of calcium sulfate Whiskers, add 20g of composite coupling agent alcoholysis solution, stir at 40°C at 300r / min for 1h, filter to obtain filter residue, put the filter residue in a drying oven, and dry at 105°C for 1h to obtain modified calcium sulfate crystals Whiskers, take 250g polyethylene resin, 400g fast-growing forest wood powder, 20g calcium carbonate, 2g antioxidant, 3g chitosan, 1g stearic acid, 0.2g polyethylene wax, 1g modified calcium sulfate whiskers, add high-speed mixing In the machine, stir at high speed until the temperature is 100°C, keep stirring for 5 minutes and cool to 40°C, then spray 1g of compound coupling agent alcoholysis solution, continue stirring for 10 minutes, and then add it to a parallel twin-screw extruder to extrud...

example 2

[0028] Take 1g of silane coupling agent KH-550 and 1g of titanate coupling agent TCA201, add it to 50g of absolute ethanol, stir at 350r / min at 50°C for 1h to obtain the alcoholysis solution of the composite coupling agent, take 1g of calcium sulfate Whiskers, add 30g of complex coupling agent alcoholysis solution, stir at 50°C at 350r / min for 1h, filter to obtain filter residue, put the filter residue in a drying oven, and dry at 120°C for 2h to obtain modified calcium sulfate crystals Whiskers, get 280g polyethylene resin, 450g fast-growing forest wood powder, 25g calcium carbonate, 2g antioxidant, 3g chitosan, 1g stearic acid, 0.2g polyethylene wax, 1g modified calcium sulfate whiskers, add high-speed mixing In the machine, stir at high speed until the temperature is 110°C, keep stirring for 8 minutes and cool to 45°C, then spray 1g of compound coupling agent alcoholysis solution, continue stirring for 12 minutes, and then add it to a parallel twin-screw extruder to extrude ...

example 3

[0030] Take 2g of silane coupling agent KH-550 and 2g of titanate coupling agent TCA201, add them to 60g of absolute ethanol, stir at 400r / min at 60°C for 2h to obtain the alcoholysis solution of the composite coupling agent, take 2g of calcium sulfate Whiskers, add 40g of composite coupling agent alcoholysis solution, stir at 60°C at 400r / min for 2h, filter to obtain filter residue, put the filter residue in a drying oven, and dry at 150°C for 3h to obtain modified calcium sulfate crystals whiskers, get 300g polyethylene resin, 500g fast-growing forest wood powder, 30g calcium carbonate, 3g antioxidant, 4g chitosan, 2g stearic acid, 0.3g polyethylene wax, 2g modified calcium sulfate whiskers, add high-speed mixing In the machine, stir at high speed until the temperature is 120°C, keep stirring for 10 minutes and cool to 50°C, then spray 2g of compound coupling agent alcoholysis solution, continue stirring for 15 minutes, and then add it to a parallel twin-screw extruder to ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com