Wheat straw fiber nonwoven mask base cloth and wheat straw fiber mask

A non-woven and wheat straw technology, applied in the direction of non-woven fabrics, textiles, papermaking, cosmetics, etc., can solve the problems of limited use of popularization, consumption of large oil resources, high consumption of disposable resources, etc., to prevent corruption and deterioration of finished products, Effects of fluffy wheat straw fiber structure and prolonged storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

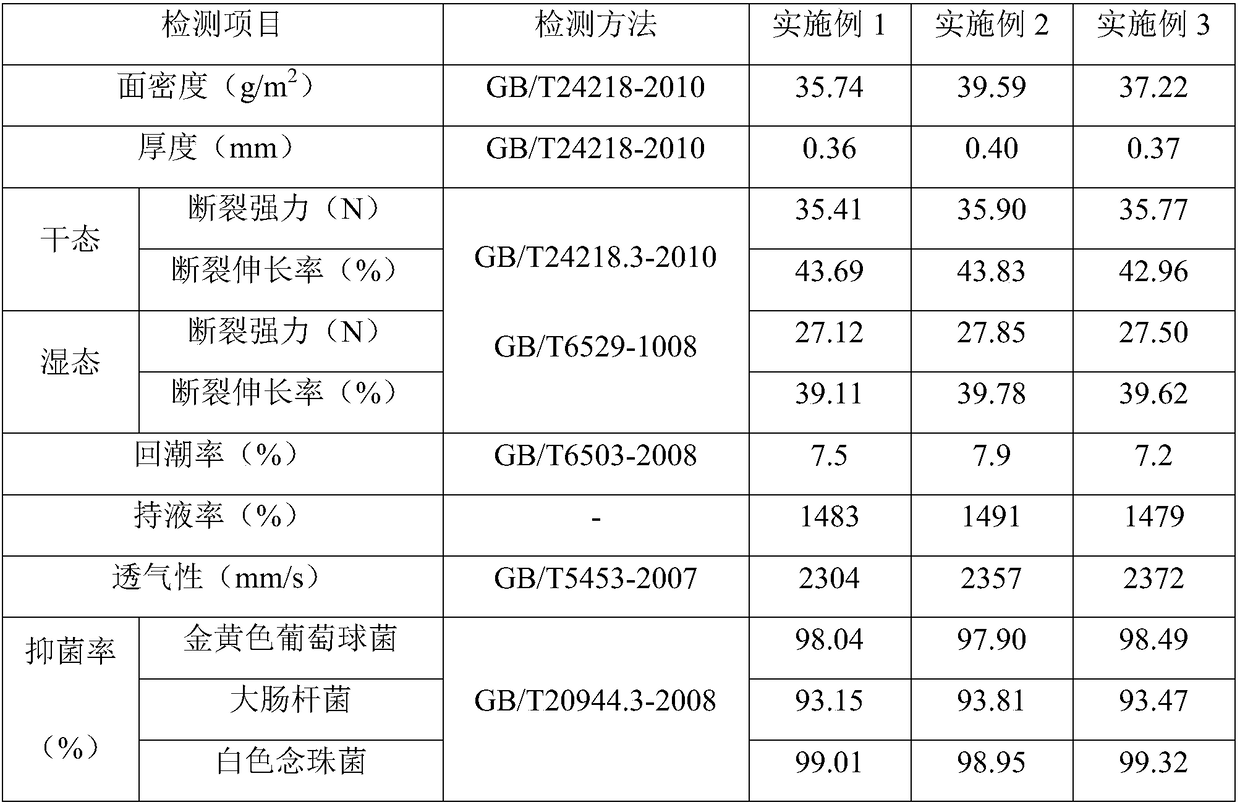

Embodiment 1

[0034] The wheat straw fiber nonwoven mask base cloth of the present embodiment is prepared by the following method:

[0035] 1) Take dried wheat straw and cut it into small sections with a length of 40-60 mm, immerse it in water at room temperature, take it out after soaking for 12 hours, squeeze and dehydrate it with rolls, and dry naturally until the water content is 40%, to obtain wheat straw scraps;

[0036] 2) Place the wheat straw scraps obtained in step 1) in a steam explosion device, inject saturated water steam to carry out steam explosion, the steam temperature is 210°C, the explosion pressure is 3.5MPa, heat preservation and pressure holding for 5.0min, the pressure is released and the material is exploded fiber material;

[0037] 3) According to the solid-to-liquid mass ratio of 1:4, immerse the blasting fiber material obtained in step 2) in water at a temperature of 65°C for washing. The soaking time for heat preservation is 6 hours. After taking it out, squeeze ...

Embodiment 2

[0044] The wheat straw fiber nonwoven mask base cloth of the present embodiment is prepared by the following method:

[0045] 1) Take dried wheat straw and cut it into small sections with a length of 40-60 mm, immerse it in water at room temperature, take it out after soaking for 14 hours, squeeze and dehydrate it with rolls, and dry it naturally until the water content is 43%, to obtain wheat straw scrap;

[0046] 2) Place the wheat straw scraps obtained in step 1) in a steam explosion device, and inject saturated steam to carry out steam explosion. The steam temperature is 215°C, the explosion pressure is 3.3MPa, and the heat preservation and pressure are kept for 4.0min. fiber material;

[0047] 3) According to the solid-to-liquid mass ratio of 1:4.5, immerse the blasting fiber material obtained in step 2) in water with a temperature of 65° C. for washing. The soaking time for heat preservation is 5 hours. After taking it out, squeeze and dehydrate to obtain the washed fibe...

Embodiment 3

[0054] The wheat straw fiber nonwoven mask base cloth of the present embodiment is prepared by the following method:

[0055] 1) Take the dry wheat straw and cut it into small sections with a length of 40-60 mm, immerse it in water at room temperature, take it out after soaking for 16 hours, squeeze and dehydrate it with rolls, and dry it naturally until the water content is 45%, to obtain wheat straw scraps;

[0056] 2) Place the wheat straw scraps obtained in step 1) in a steam explosion device, inject saturated water steam to carry out steam explosion, the steam temperature is 220°C, the explosion pressure is 3.0MPa, heat preservation and pressure holding for 5.0min, and the pressure is released to discharge the material. fiber material;

[0057] 3) According to the solid-to-liquid mass ratio of 1:5, immerse the blasting fiber material obtained in step 2) in water at a temperature of 65° C. for washing, and keep the soaking time for 4 hours. After taking it out, squeeze and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com