A method for treating waste water containing phenolic sodium sulfate from tar refining with environmental protection and low energy consumption

A technology for sodium phenol sulfate and waste water treatment, which is applied in multi-stage water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. The effect of no secondary pollution and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

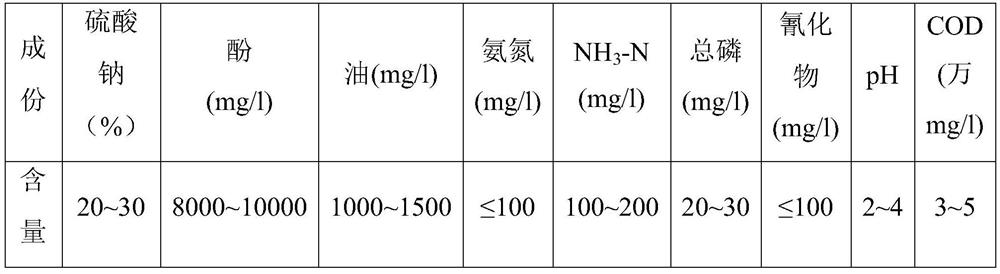

[0032] Example 1, the quality of the wastewater to be treated is as follows:

[0033]

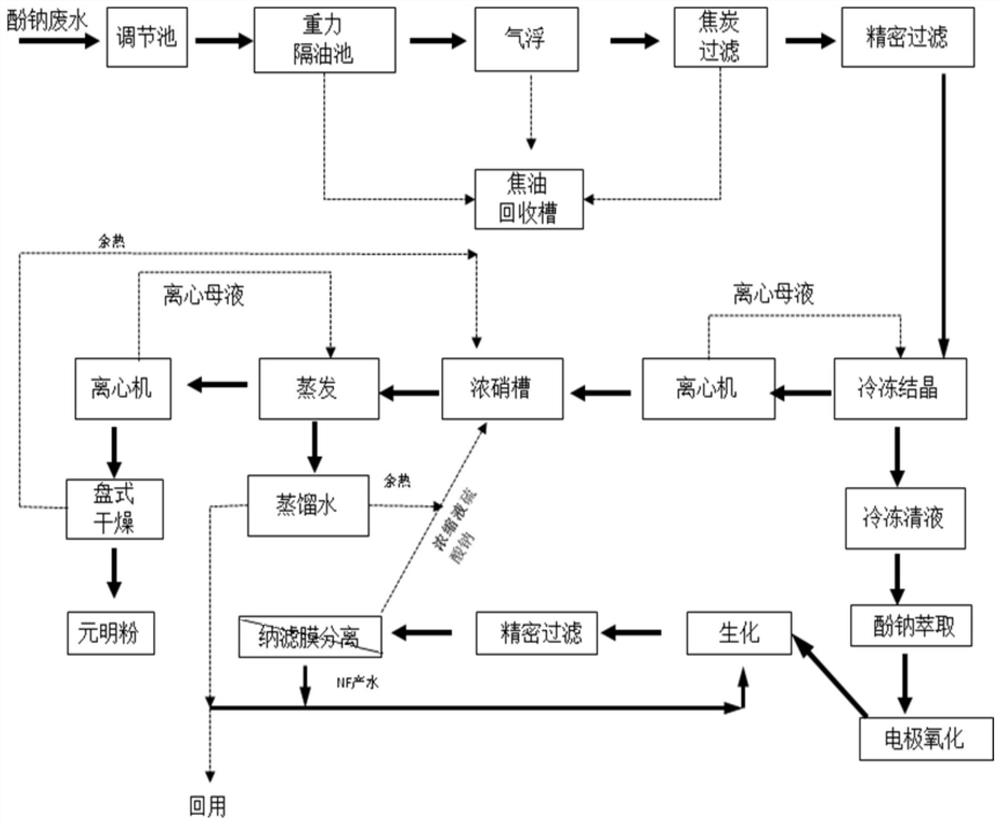

[0034] Using the waste water treatment process of the present invention, successively undergo demulsification and gravity oil separation, further oil removal by air flotation, complete oil removal by coke filtration, fine filtration to remove suspended solids and colloids, freezing and crystallization at 0-5°C to precipitate sodium sulfate decahydrate, Separation and recovery of the phenol-rich solution in the upper layer, centrifugal purification of sodium sulfate decahydrate crystals, redissolution of sodium sulfate decahydrate crystals, further purification by evaporation and crystallization, and disc drying and dehydration drying, can obtain high-purity anhydrous sodium sulfate. The grade quality of sodium sulfate reaches The national standard GB6009-2014III qualified products require that the upper phenol-containing solution obtained by freezing and separating and the distilled water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com