Preparation method of carbon-silver microsphere/epoxy resin super-hydrophobic coating

A super-hydrophobic coating, epoxy resin technology, applied in epoxy resin coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of high production cost of super-hydrophobicity, single preparation method, and strong substrate dependence. , to achieve the effects of strong chemical stability and thermal stability, easy availability of raw materials and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of flower-like carbon-silver microspheres:

[0036] Dissolve 1.25 g of silver nitrate in a mixed solution of 80 mL of water and 40 mL of ethanol, and add a certain amount of ammonia water (0.02 M) dropwise under magnetic stirring to adjust the pH to about 8.5. 50 mL of 20 mg / mL dopamine hydrochloride solution was added dropwise to the system, and the reaction was continued for 12 h. After the reaction, it was suction filtered and placed in a -25 °C refrigerator for 24 h. Then calcined at 450 °C for 3 h in a sealed muffle furnace to obtain a black powder product, thus completing the preparation of flower-like carbon-silver microspheres.

[0037] (2) Low surface energy modification:

[0038] Add the carbon-silver microsphere powder product prepared in step A to 50 ml of 0.5% perfluorooctyltriethoxysilane n-hexane solution, and stir to disperse it. After reacting for 20 min, the modified white powder was obtained by centrifugation, washing with n-hexane ...

Embodiment 2

[0042] (1) Preparation of flower-like carbon-silver microspheres:

[0043] Dissolve 1.25 g of silver nitrate in a mixed solution of 80 mL of water and 40 mL of ethanol, and add a certain amount of ammonia water (0.02 M) dropwise under magnetic stirring to adjust the pH to about 8.5. 50 mL of 20 mg / mL dopamine hydrochloride solution was added dropwise to the system, and the reaction was continued for 12 h. After the reaction, it was suction filtered and placed in a -25 °C refrigerator for 24 h. Then calcined at 450 °C for 3 h in a sealed muffle furnace to obtain a black powder product, thus completing the preparation of flower-like carbon-silver microspheres.

[0044] (2) Low surface energy modification:

[0045] Add the carbon-silver microsphere powder product prepared in step A to 50 ml of 0.5% perfluorooctyltriethoxysilane n-hexane solution, and stir to disperse it. After reacting for 20 min, the modified white powder was obtained by centrifugation, washing with n-hexane ...

Embodiment 3

[0049] (1) Preparation of flower-like carbon-silver microspheres:

[0050] Dissolve 1.25 g of silver nitrate in a mixed solution of 80 mL of water and 40 mL of ethanol, and add a certain amount of ammonia water (0.02 M) dropwise under magnetic stirring to adjust the pH to about 8.5. 50 mL of 20 mg / mL dopamine hydrochloride solution was added dropwise to the system, and the reaction was continued for 12 h. After the reaction, it was suction filtered and placed in a -25 °C refrigerator for 24 h. Then calcined at 450 °C for 3 h in a sealed muffle furnace to obtain a black powder product, thus completing the preparation of flower-like carbon-silver microspheres.

[0051] (2) Low surface energy modification:

[0052] Add the carbon-silver microsphere powder product prepared in step A to 50 ml of 0.5% perfluorooctyltriethoxysilane in n-hexane solution, and stir to disperse it. After reacting for 20 min, the modified white powder was obtained by centrifugation, washing with n-hexa...

PUM

| Property | Measurement | Unit |

|---|---|---|

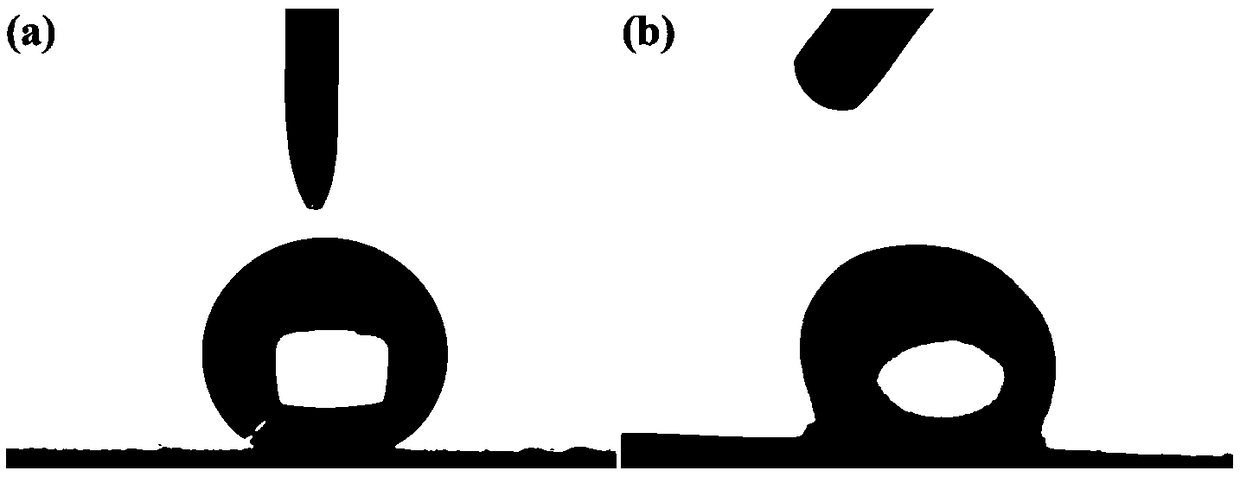

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com