A kind of vitrified high-energy-saving coating and its preparation method and application

An energy-saving paint and paint technology, applied in the field of paint, can solve problems such as unenvironmental protection, heat loss, energy waste, etc., and achieve the effects of protecting the heating surface, improving absorption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A vitrified high-energy-saving paint, including functional materials and bonding materials, the mass ratio of the two is 5:5; the functional materials, based on the total mass percentage of 100%, include antimony powder: 35%, zirconium powder 25%, tin powder 15%, titanium powder 5%, copper powder 5%, mullite powder 5%, titanium dioxide 5%, andalusite powder 1.5%, silicon carbide powder 2%, diatomite powder 1%, bentonite 0.5 %; The bonding material is silicone resin.

[0019] The preparation method of the coating comprises the following steps: dosing according to the proportions of the above components, and mixing uniformly to obtain functional materials; mixing and dispersing the functional materials and bonding materials for 1-2 hours; then performing ball milling for 6-8 hours, and using a 325-mesh Just filter it.

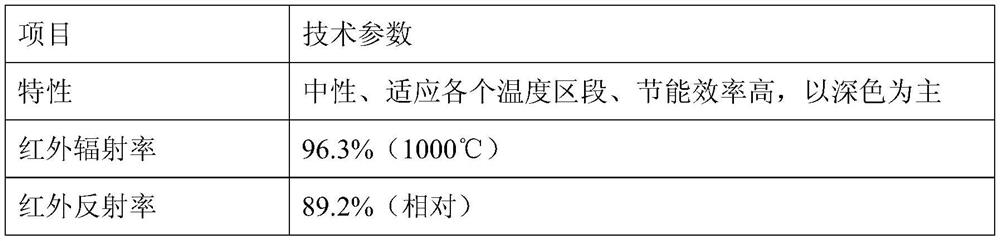

[0020] Present embodiment coating technical index is as shown in table 1:

[0021] Table 1

[0022] project Technical Parameters charac...

Embodiment 2

[0024] A vitrified high-energy-saving paint, including functional materials and bonding materials, the mass ratio of the two is 3:7; the functional materials, based on the total mass percentage of 100%, include antimony powder: 33%, zirconium powder 27%, tin powder 12%, titanium powder 7%, copper powder 7%, mullite powder 3%, titanium dioxide 7%, andalusite powder 1.2%, silicon carbide powder 1.8%, diatomite powder 0.8%, bentonite 0.2 %; The bonding material is boron phenolic resin (FB resin).

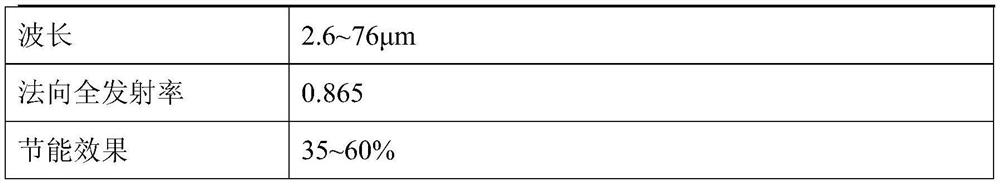

[0025] The coating technical index of the present invention is as shown in table 2:

[0026] Table 2

[0027] project Technical Parameters characteristic Neutral, suitable for various temperature ranges, high energy saving efficiency, mainly in dark colors Infrared emissivity 96.1%(1000℃) Infrared reflectivity 89.1% (relative) wavelength 2.6~76μm full normal emissivity 0.861 energy saving effect 32~60%

Embodiment 3

[0029] A vitrified high-energy-saving paint, including functional materials and bonding materials, the mass ratio of the two is 4:6. The functional material includes antimony powder: 38%, zirconium powder 23%, tin powder 17%, titanium powder 3%, copper powder 3%, mullite powder 7%, titanium dioxide powder 3% based on the total mass percentage of 100%. %, 1.7% of andalusite powder, 2.3% of silicon carbide powder, 1.3% of diatomite powder, and 0.7% of bentonite; the bonding material is high temperature resistant resin, selected from more than one of silicone resin and boron phenolic resin. The bonding material is silicone resin, boron phenolic resin.

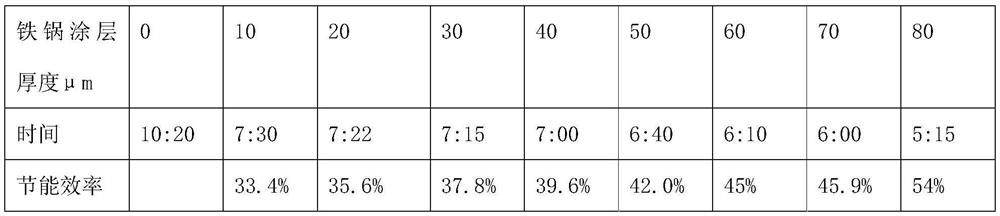

[0030] The coating technical index of the present invention is as shown in table 3:

[0031] table 3

[0032]

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com