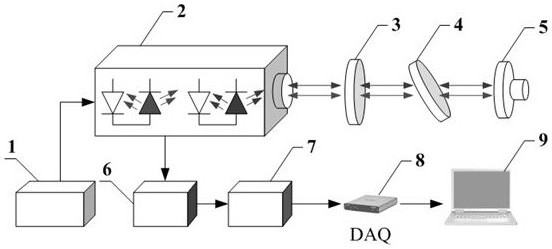

A dual-wavelength ld self-mixing vibration measuring instrument with adjustable resolution and its measuring method

A technology of vibration measurement and measurement method, which is applied in the field of precision optical interferometry, can solve the problems of difficulty in adjusting the irradiation of discrete structures at the same point, high requirements for output laser polarization, and single and non-adjustable measurement resolution, achieving low cost, stable optical power, Effects requiring low roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

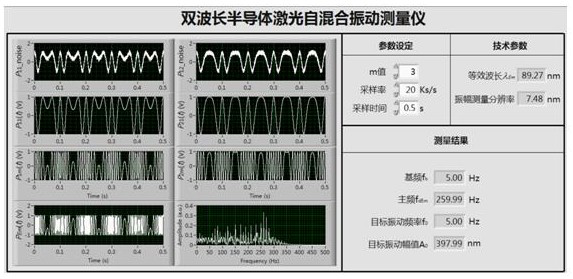

[0078] (1) Example 1: Fix the target 5 to be measured on the vertical surface on the vibration source, the vibration amplitude is 393nm (0.6λ 1 ), the vibration frequency is 5Hz;

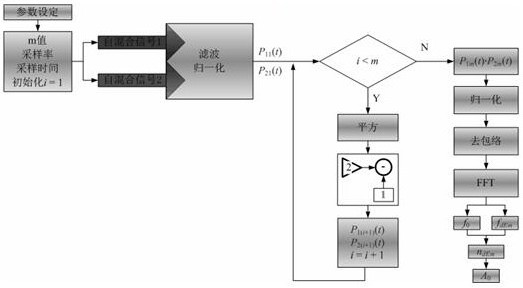

[0079] (2) Computer data analysis and processing, setting sampling rate 20Ks / s, sampling time is 0.5s and m=3; Calculate λ according to the formula E3 The value of is 89.27nm, and the amplitude measurement resolution is 7.48nm; set the loop variable i=1;

[0080] (3) The data acquisition card 8 collects the two-way self-mixing signals and removes the high-frequency noise through filtering, and then normalizes them respectively so that the amplitude of the signals is 1, and obtains P 11 (t) and P 21 (t);

[0081] (4) i11 (t) and P 21 (t) Square and enlarge by 2 times, then subtract 1 to get P 12 (t) and P 22 (t); loop variable i=i+1=2;

[0082] (5) i12 (t) and P 22 (t) Square and enlarge by 2 times, then subtract 1 to get P 13 (t) and P 23 (t); loop variable i=i+1=3;

[0083] (6) i≥m, i.e....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com