Magnetic oxidized graphene/polyethyleneimine adsorbent and preparation method and application thereof

A technology of polyethyleneimine and oxidized rock, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve separation problems, achieve easy access to raw materials, achieve rapid separation, and increase adsorption sites Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

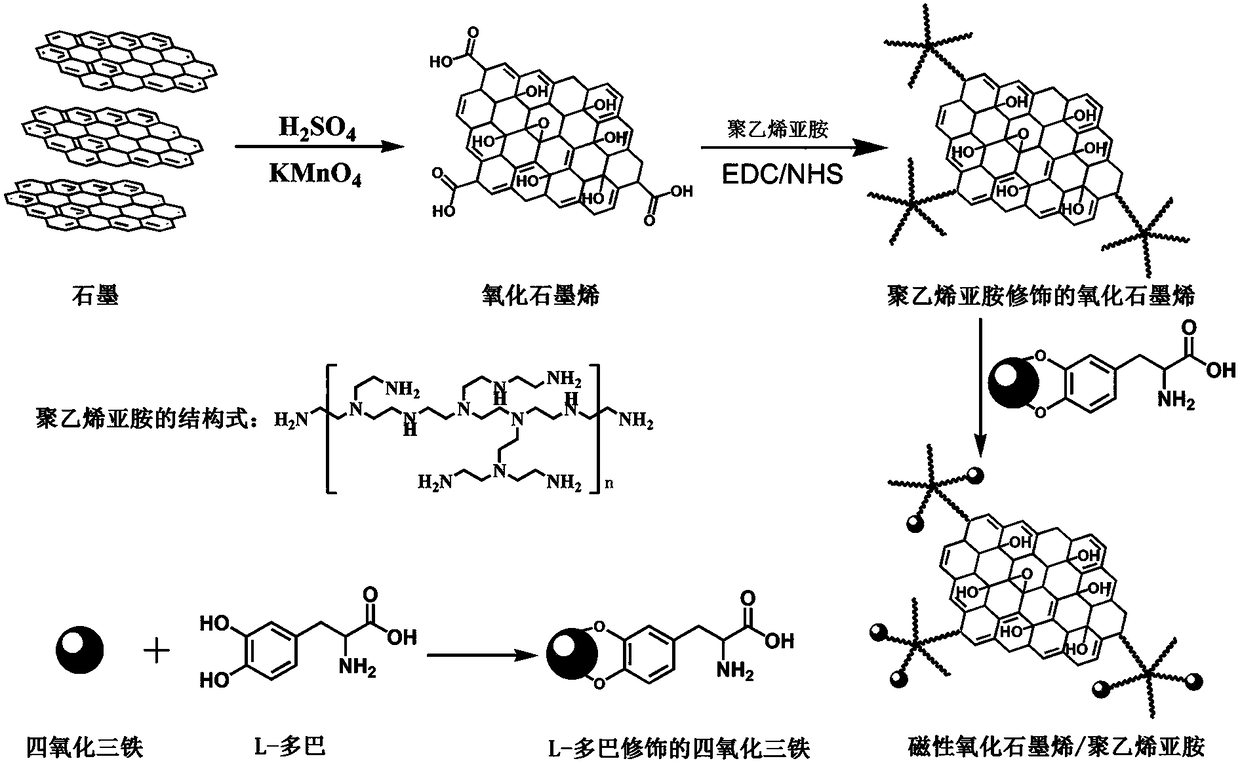

[0034] The specific steps of the preparation method of magnetic graphene oxide / polyethyleneimine are as follows:

[0035] (1) Preparation of graphene oxide

[0036] Weigh 5 g of graphite powder and 115 mL of concentrated sulfuric acid in a 500 mL three-necked flask, and mechanically stir for 30 min in an ice-water bath. Weigh 15g KMnO 4 Slowly add to the reaction system in 3 times and keep the system temperature below 5 °C. Wait for KMnO 4 After the addition was complete, the reaction bottle was moved to a constant temperature water bath at 35 °C and stirred for 2.5 h. Then 230 mL of ultrapure water was added at one time, and mechanically stirred in a constant temperature oil bath at 100 °C for 45 min. Subsequently, the reaction bottle was removed and the reaction solution was transferred to a 1 L beaker. When the temperature of the system dropped to 50 °C, 700 mL of ultrapure water and 12.5 mL of 30% hydrogen peroxide were added at one time. Then, filter under normal pre...

Embodiment 2

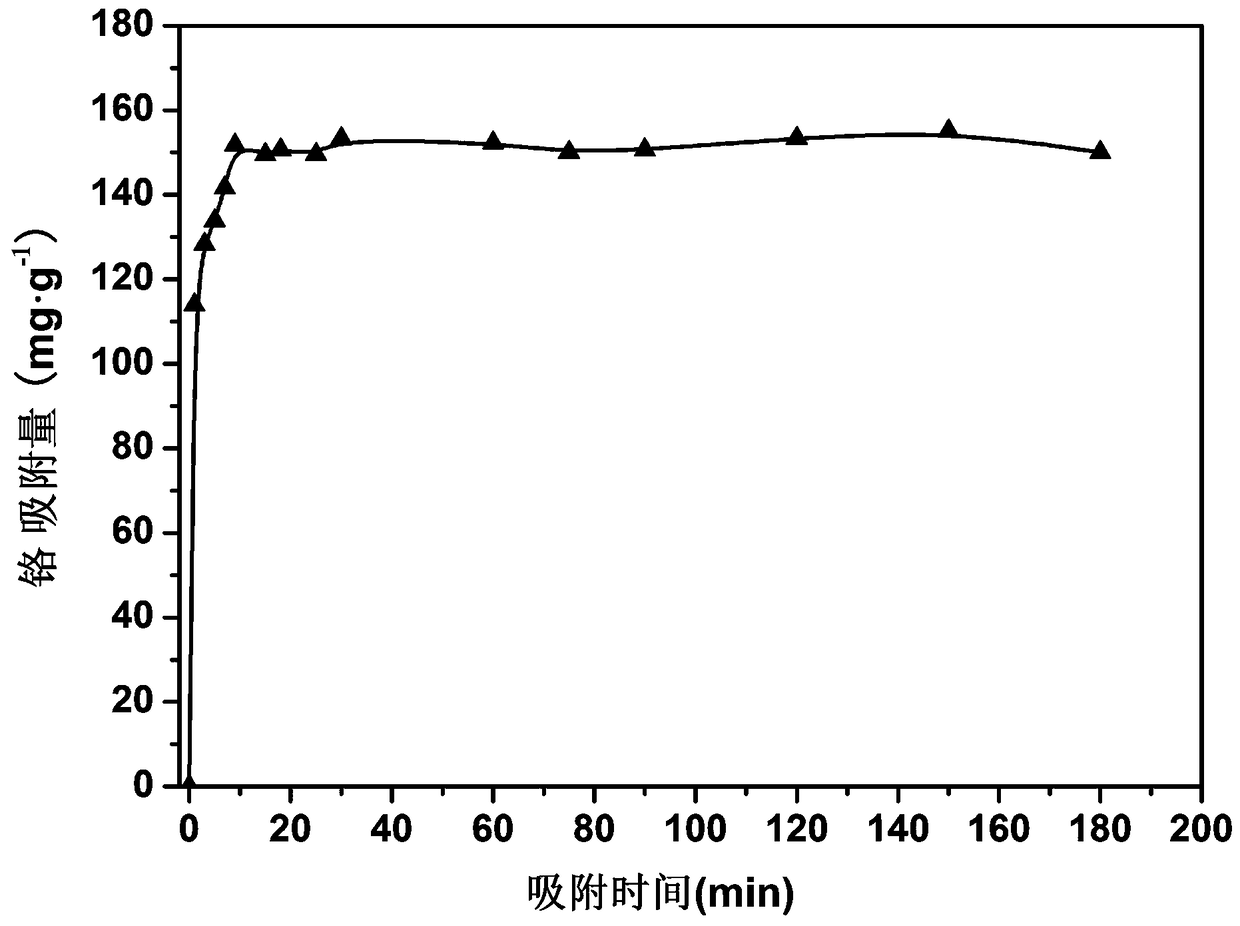

[0048] The adsorption amount of magnetic graphene oxide / polyethyleneimine adsorbent to hexavalent chromium ion is calculated according to the following formula: Q = (C 1 -C 2 )VM / m; where Q: adsorption capacity (mg / g); C 1 : Chromium ion concentration before adsorption (mmol / L); C 2 : concentration of chromium ion after adsorption (mmol / L); V: volume of adsorption solution (L); m: mass of magnetic graphene oxide / polyethyleneimine (g); M: atomic weight of chromium (g / mol).

[0049] The adsorption capacity of magnetic graphene oxide / polyethyleneimine to hexavalent chromium ions was determined by ultraviolet-visible spectrophotometry. The specific steps are as follows:

[0050] (1) Exploration of adsorption time: Accurately weigh 10 mg of magnetic graphene oxide / polyethyleneimine adsorbent into 30 mL, 2 mmol / L solution of hexavalent chromium ions at pH=3.00, and stir at 25°C , respectively reacting 0 min, 1 min, 3 min, 5 min, 7 min, 9 min, 15 min, 18 min, 25 min, 30 min, 60 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com