Preparation method and system of potassium hydrogen fluoride

A technology of potassium hydrogen fluoride and potassium hydroxide, applied in the field of the preparation method of potassium hydrogen fluoride and the preparation system thereof, can solve the problems of large reaction exotherm, high local temperature, unstable product yield and the like, and achieves small particle size and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation of embodiment 1 potassium hydrogen fluoride

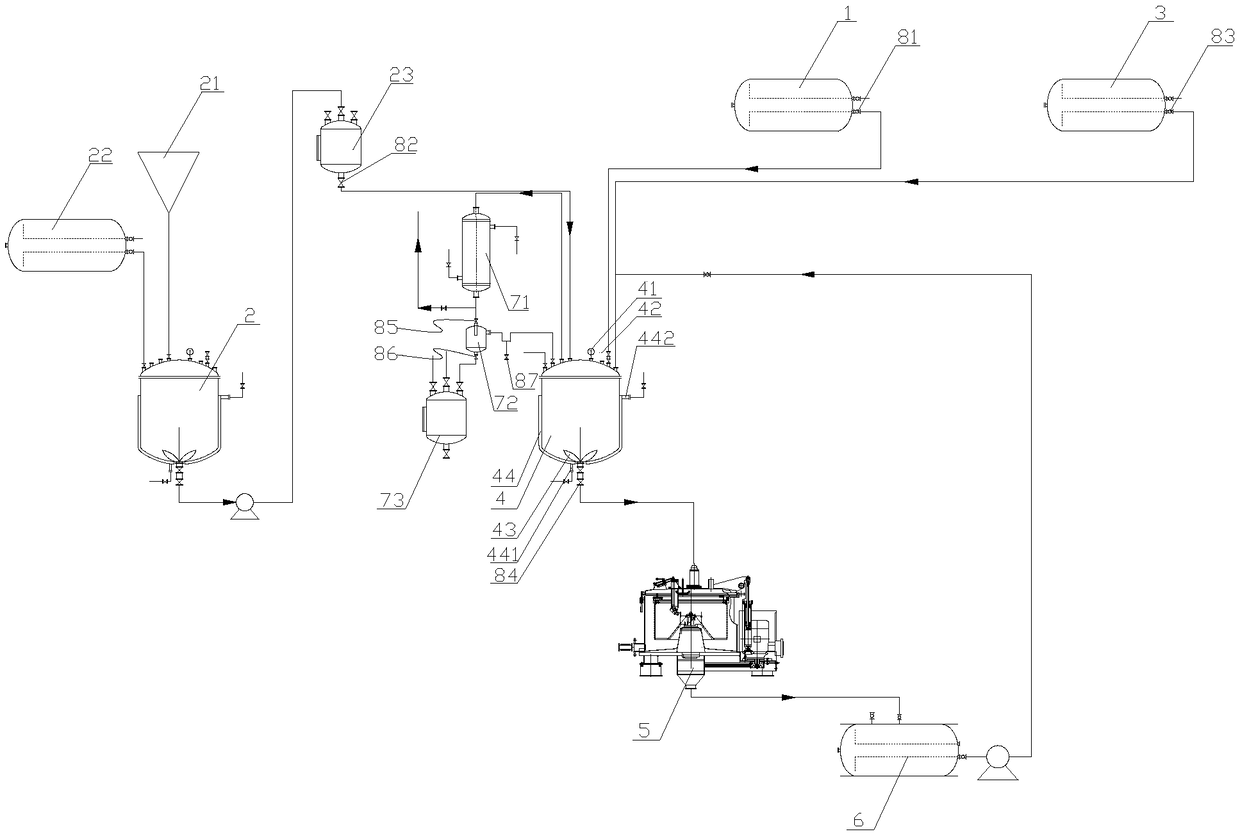

[0056] see figure 1 , the inventor also provides a system for preparing potassium hydrogen fluoride, comprising an anhydrous hydrogen fluoride tank 1, a potassium hydroxide tank 2, an anhydrous organic solvent tank 3, a reaction kettle 4, a centrifuge 5, a mother liquor tank 6, a condensation device, and a thermometer 41 and a pH meter 42;

[0057] In this embodiment, the potassium hydroxide solid is mixed with the organic solvent in the potassium hydroxide tank, and the potassium hydroxide tank is externally connected with the potassium hydroxide solid tank 21 and the organic solvent tank 22, and the potassium hydroxide solid tank is filled with the potassium hydroxide solid , the organic solvent tank is used to hold methanol, ethanol, acetonitrile, dichloromethane or their mixture, dissolve potassium hydroxide in the organic solvent, and configure the potassium hydroxide solution. The structure of the pot...

Embodiment 2

[0076] The preparation of embodiment 2 potassium hydrogen fluoride finished products

[0077] The difference between embodiment 2 and embodiment 1 is that the organic solvent used in embodiment 2 is ethanol; the mass percentage of potassium hydroxide solution is 40%.

[0078] The solubility of anhydrous hydrofluoric acid in ethanol at 25°C is 50g, and the solubility of potassium hydrogen fluoride in ethanol is less than 0.1g. Finally, a total of 565 kg of white solid potassium hydrogen fluoride was obtained, with a purity of 99.4% and a yield of 99%.

Embodiment 3

[0079] The preparation of embodiment 3 potassium hydrogen fluoride finished products

[0080] The difference between embodiment 3 and embodiment 1 is that acetonitrile is used as the organic solvent in embodiment 3; the mass percentage of potassium hydroxide solution is 30%.

[0081] The solubility of anhydrous hydrofluoric acid in acetonitrile at 25°C is 48g. The solubility of the potassium hydrogen fluoride in methanol is less than 0.1g. Finally, 566 kg of white solid potassium hydrogen fluoride was obtained. The purity is 99.8%, and the yield is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com