Large-volume concrete and preparation method thereof

A technology of mass concrete and bentonite, which is applied in the field of building materials, can solve the problems of reduced physical and mechanical properties of concrete, easy penetration of erosive media, and reduced service life of concrete, so as to reduce hydration heat and heat release rate, and reduce defects. Risk, effect of reducing early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

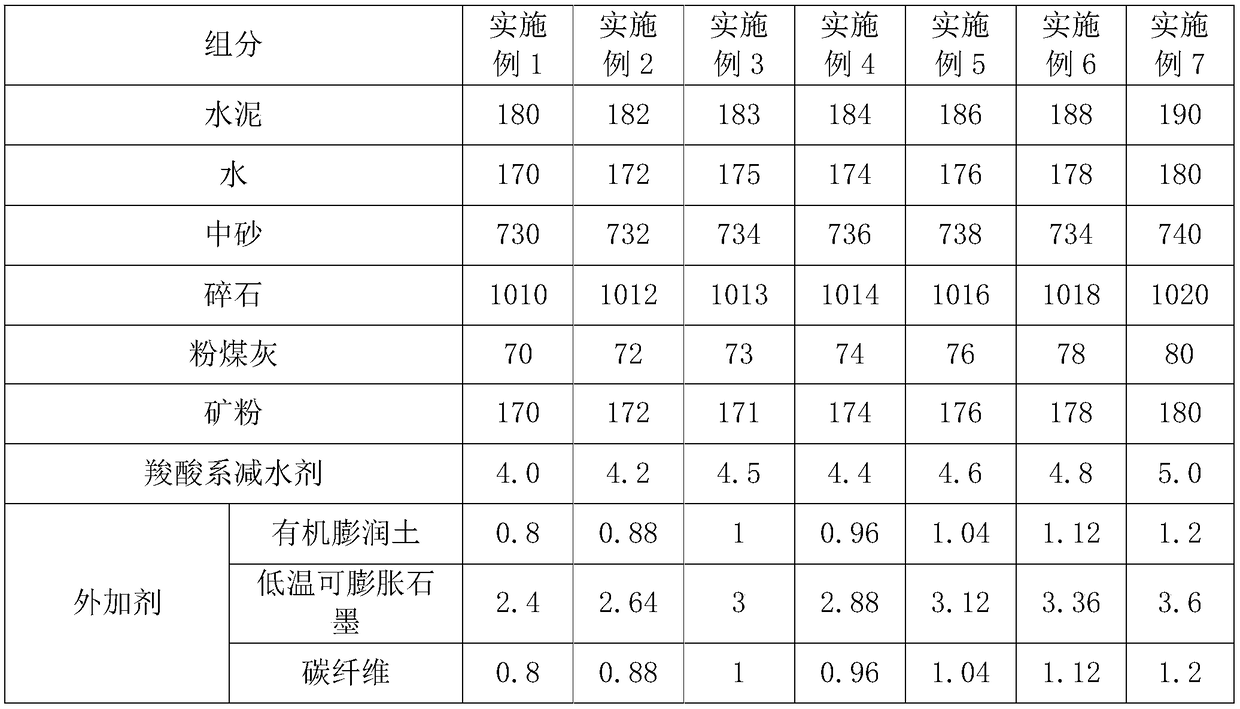

[0038] Embodiment 1: a kind of mass concrete is prepared by the following method:

[0039] S1: Fully mix 180kg cement, 730kg medium sand, 1010kg gravel, 70kg fly ash, 170kg mineral powder, 4kg polycarboxylate water reducer, 0.8kg organic bentonite and 2.4kg low-temperature expandable graphite to obtain the first mixture ;

[0040] S2: add the water of 136kg in the first mixture, fully mix, obtain the second mixture;

[0041] S3: Add 0.8 kg of carbon fiber and 34.4 kg of water to the second mixture, and mix thoroughly to obtain large-volume concrete.

[0042] Among them, the cement is P LH42.5 low-heat Portland cement with a specific surface area of 350m 2 / kg; the fineness modulus of medium sand is 3.0; the particle size of gravel is 5-25mm continuous gradation, and the apparent density of gravel is 2840kg / m 3 , the loose bulk porosity is 47%, and the loose bulk density is 1565kg / m 3 ; The fly ash is class F class II fly ash, the fineness of the fly ash (45μm square hole...

Embodiment 2

[0043] Embodiment 2: a kind of mass concrete is prepared by the following method:

[0044] S1: Fully mix 182kg of cement, 732kg of medium sand, 1012kg of gravel, 72kg of fly ash, 172kg of mineral powder, 4.2kg of polycarboxylate water reducer, 0.88kg of organic bentonite and 2.64kg of low-temperature expandable graphite to obtain the first mixture;

[0045] S2: add the water of 137.6kg in the first mixture, fully mix, obtain the second mixture;

[0046] S3: Add 0.88kg of carbon fibers and 34.4kg of water to the second mixture, and mix thoroughly to obtain large-volume concrete.

[0047] Among them, the cement is P LH42.5 low-heat Portland cement with a specific surface area of 350m 2 / kg; the fineness modulus of medium sand is 3.0; the particle size of gravel is 5-25mm continuous gradation, and the apparent density of gravel is 2840kg / m 3 , the loose bulk porosity is 47%, and the loose bulk density is 1565kg / m 3 ; The fly ash is class F class II fly ash, the fineness of ...

Embodiment 3

[0048] Embodiment 3: a kind of mass concrete is prepared by the following method:

[0049] S1: Fully mix 183kg cement, 734kg medium sand, 1013kg gravel, 73kg fly ash, 171kg mineral powder, 4.5kg polycarboxylate water reducer, 1kg organic bentonite and 3kg low-temperature expandable graphite to obtain the first mixture;

[0050] S2: add the water of 140kg in the first mixture, fully mix, obtain the second mixture;

[0051] S3: Add 1 kg of carbon fiber and 35 kg of water to the second mixture, and mix thoroughly to obtain large-volume concrete.

[0052] Among them, the cement is P LH42.5 low-heat Portland cement with a specific surface area of 350m 2 / kg; the fineness modulus of medium sand is 3.0; the particle size of gravel is 5-25mm continuous gradation, and the apparent density of gravel is 2840kg / m 3 , the loose bulk porosity is 47%, and the loose bulk density is 1565kg / m 3 ; The fly ash is class F class II fly ash, the fineness of the fly ash (45μm square hole sieve r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com