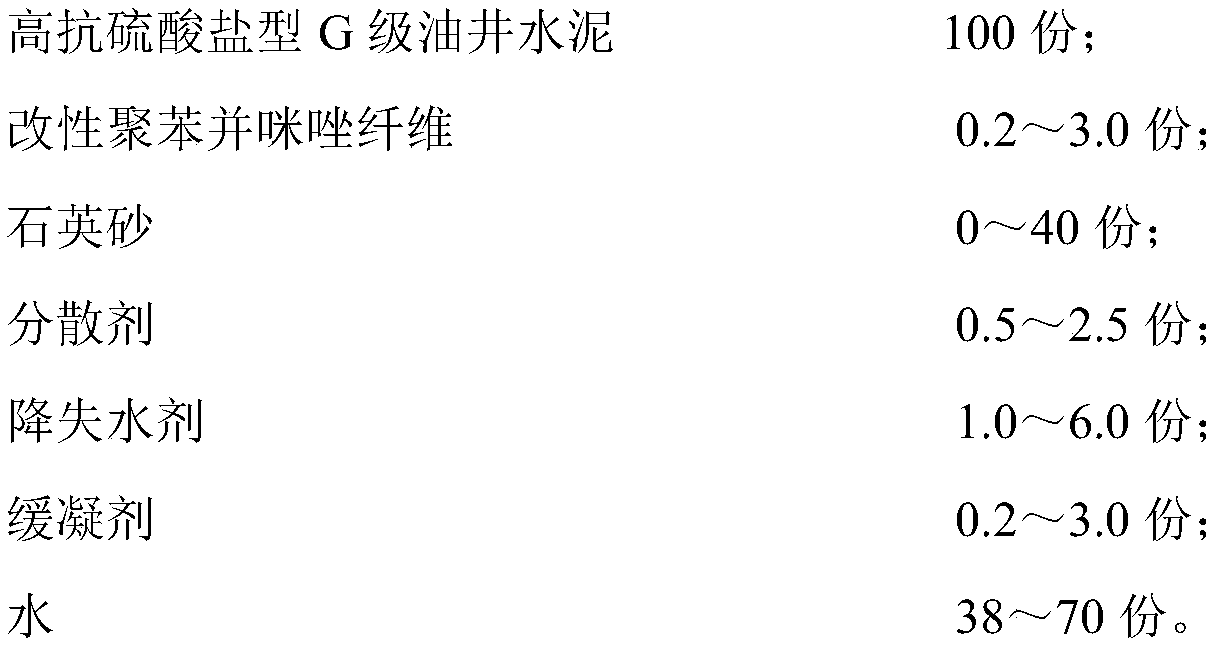

Modified polybenzimidazole fiber reinforcement cement paste system

A polybenzimidazole and benzimidazole technology, applied in the fiber type, fiber treatment, ultrasonic/sonic fiber treatment and other directions, can solve the problems of fiber toughening effect failure, difficult comprehensive performance, poor compatibility with cement slurry, etc. The effect of improved mechanical properties, good bonding degree and good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

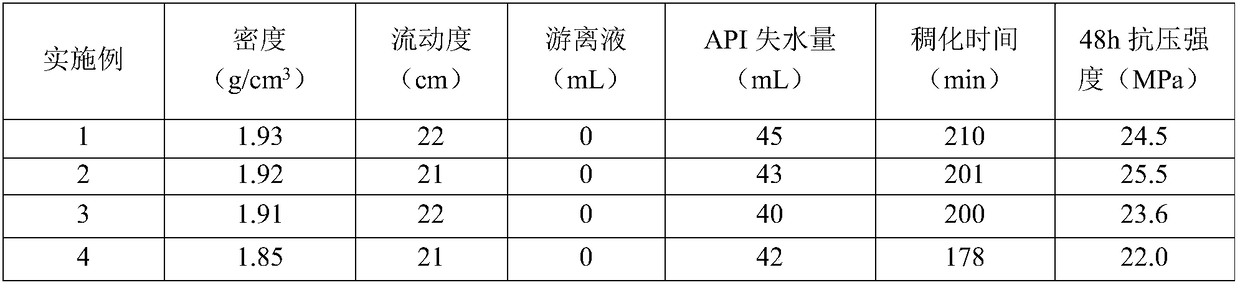

Examples

Embodiment 1

[0029] Embodiment 1 (blank cement slurry system)

[0030] Formula: 100 parts of high sulfate-resistant grade G oil well cement, 0.5 parts of sodium polystyrene sulfonate, 1.0 parts of polyvinylpyrrolidone, 0.2 parts of sodium gluconate and 40 parts of water.

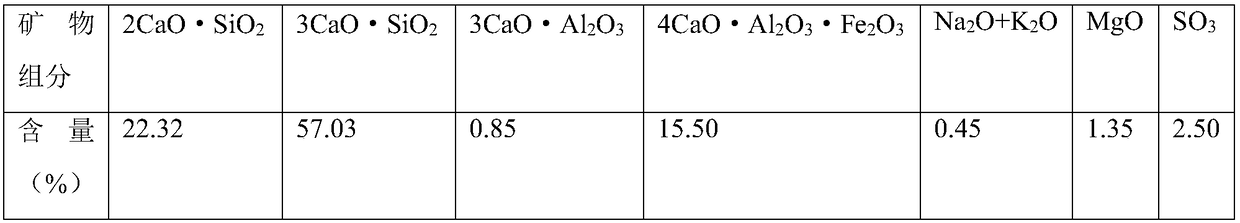

[0031] The mineral components of high sulfate-resistant grade G oil well cement are shown in Table 1.

[0032] Table 1 Mineral components of high sulfate-resistant grade G oil well cement

[0033]

Embodiment 2

[0035] Formula: 100 parts of high sulfate-resistant grade G oil well cement, 0.8 parts of modified polybenzimidazole fiber, 0.5 parts of sodium polystyrene sulfonate, 1.0 part of polyvinylpyrrolidone, 0.2 parts of sodium gluconate and 40 parts of water.

[0036] The composition of the high sulfate-resistant type G grade oil well cement is the same as in Example 1.

[0037] The process of preparing modified polybenzimidazole fiber is as follows:

[0038] 1) Chopping polybenzimidazole fibers to obtain chopped polybenzimidazole fibers with an average length of 300 μm; 2) adding chopped polybenzimidazole fibers to a beaker, and then weighing 97% concentrated nitric acid Measure 200mL into the beaker, stir well, seal it with plastic wrap and tie it tightly with a rubber band. Put the beaker into the water bath and fix it. The heating temperature of the water bath is 60° C., and the constant temperature heating treatment is carried out for 3 hours. After the treatment, take out th...

Embodiment 3

[0040] Formula: 100 parts of high sulfate-resistant grade G oil well cement, 1.5 parts of modified polybenzimidazole fiber, 0.6 parts of polynaphthalene sodium sulfonate, 1.5 parts of hydroxyethyl cellulose, 0.3 parts of sodium borate and 44 parts of water.

[0041] The composition of the high sulfate-resistant type G grade oil well cement is the same as in Example 1. The composition and preparation of the modified polybenzimidazole fiber are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com