Lactobacillus plantarum capable of producing ferulic acid esterase

A technology of Lactobacillus plantarum and ferulic acid esterase, applied in the direction of Lactobacillus, bacteria used in food preparation, bacteria, etc., can solve the problems of limiting cellulose utilization and degradation, achieve wide application value, improve fermentation quality, improve The effect of digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Screening experiment of strains producing ferulic acid esterase.

[0029] 1. Activate the lactic acid bacteria 2-3 times, streak on the MRS solid medium, and culture for 2 days at 37°C.

[0030] 2. Pick a single colony on the MRS solid medium without glucose, and use ethyl ferulate as the sole carbon source. Add 0.3ml of ethyl ferulate solution to each plate (dissolve ethyl ferulate in Dimethylformamide was made into a solution with a mass-volume ratio of 10%), cultured at 30°C for 72 hours, and observed whether a transparent bacterial circle appeared on the plate.

[0031] 3. It can be preliminarily judged to produce ferulic acid esterase. The tested Lactobacillus plantarum FE1 produced transparent circles.

Embodiment 2

[0032] Example 2: Crude enzyme solution for liquid culture and enzyme activity analysis and determination.

[0033] 1. After the initial screening, the Lactobacillus plantarum FE1 strain was cultured in MRS liquid medium at 37°C overnight, centrifuged at 3000 rpm for 5 min, and the bacteria were collected.

[0034] 2. Wash the bacteria 3 times with 0.85% normal saline and resuspend in deionized water.

[0035] 3. Take bacteria suspension (fixed bacteria number 1×10 9 cfu / ml) was inoculated into the medium containing methyl ferulate, 100ml medium was added with 5ml methyl ferulate (1% W / V dimethylformamide), the inoculation amount of the strain was 2% (V / V), ferment. The fermentation conditions were 37°C, 48h, and the oscillation frequency was 120rpm.

[0036] 4. Pipette 9ml of fermentation broth into a 10ml centrifuge tube, centrifuge at 10000rpm for 10min, the supernatant is the crude ferulic acid esterase enzyme solution, which is used for enzyme activity determination.

[0037] 5....

Embodiment 3

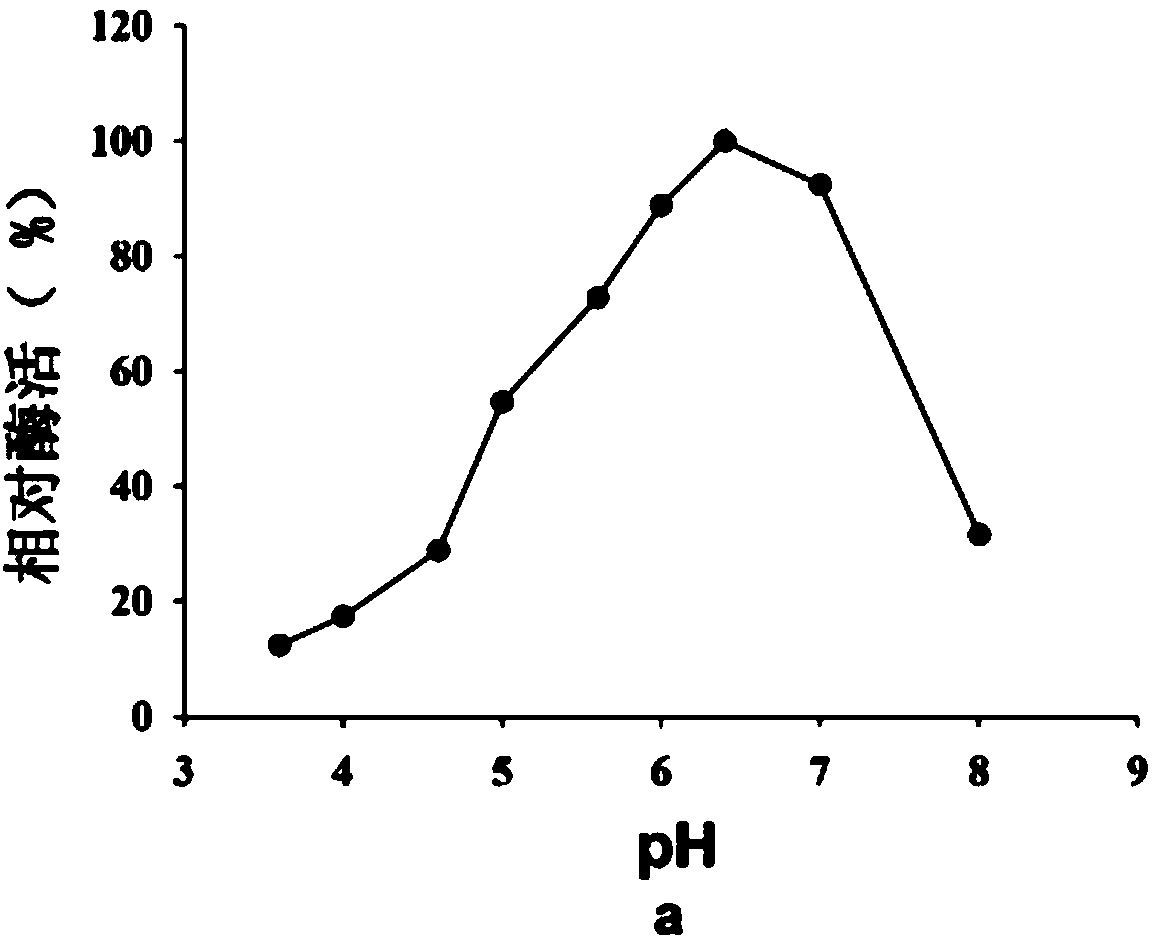

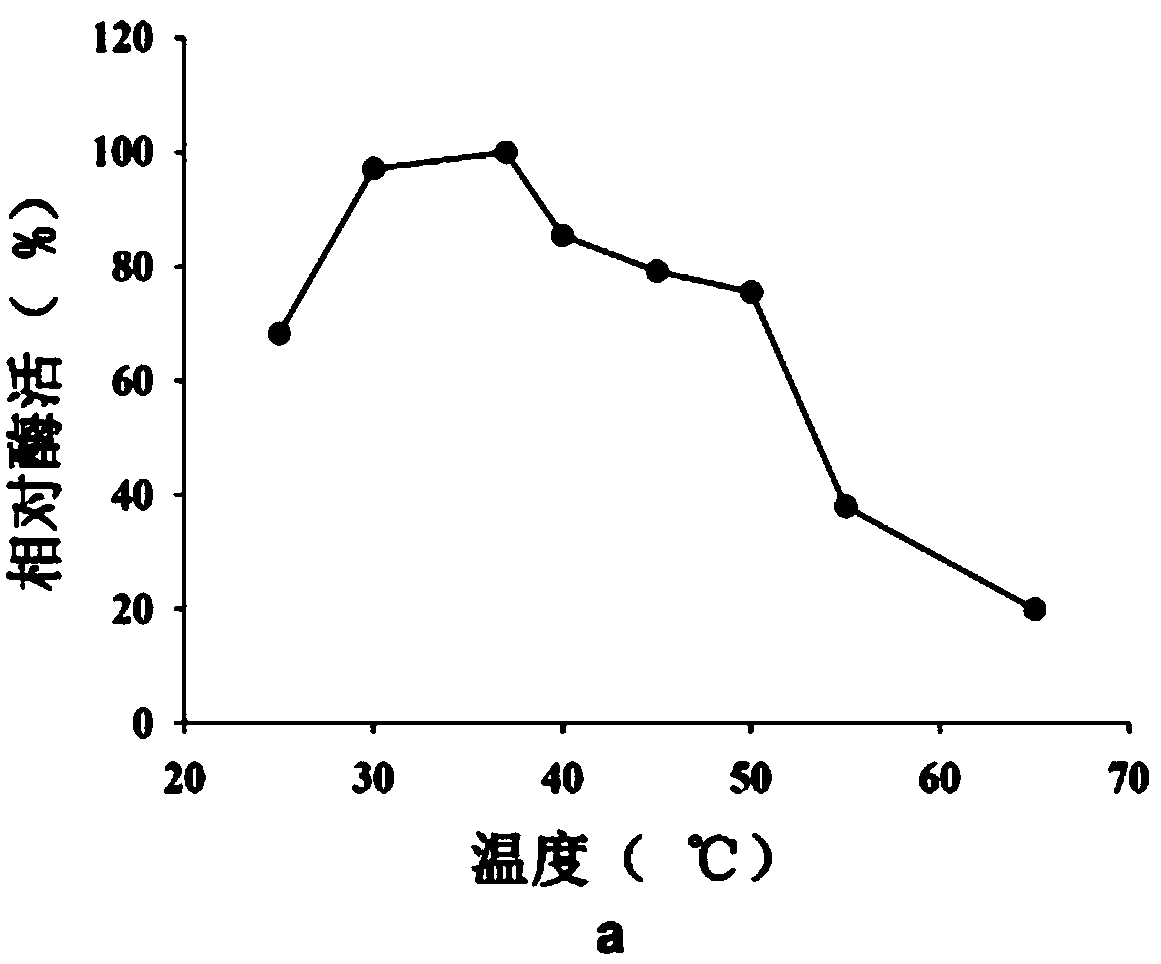

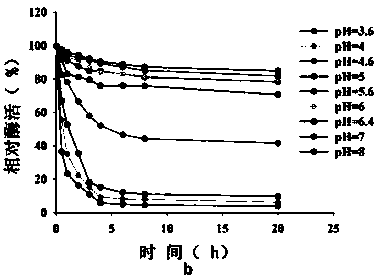

[0045] Example 3: Analysis and determination of physicochemical properties of FAE-producing Lactobacillus plantarum FE1.

[0046] 1. Sugar fermentation, arginine ammonia production, nitrate reduction and glucose gas production.

[0047] Using bacteria micro biochemical reaction tube.

[0048] The strain is activated for 2-3 times, streaked and cultured for 2-3 days, a single colony is picked with an inoculation loop and placed in a biochemical tube, sealed with sterilized glycerin, and incubated at 37°C for 2-3 days to observe its discoloration.

[0049] Table 2 The utilization ability of the lactic acid bacteria of the present invention on the sugar source.

[0050]

[0051] Note: "+" means using the sugar; "—" means not using the sugar. CGMCC, China Microorganism Collection. C-LP, the standard strain of Lactobacillus plantarum. LP, Lactobacillus plantarum.

[0052] 2. Strain growth characteristics under different temperature conditions.

[0053] After activating the lactic acid bacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com