Method for detecting silicon dioxide in foods and food additives

A technology for food additives and detection methods, applied in the field of food analysis, can solve the problems of low accuracy, cumbersome operation, and high detection limit, and achieve the effects of high accuracy, overcoming low accuracy and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

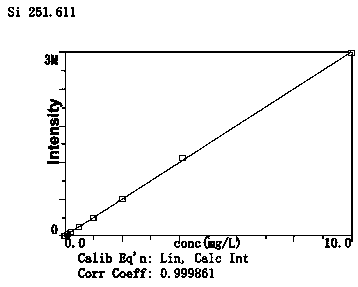

Image

Examples

Embodiment 1

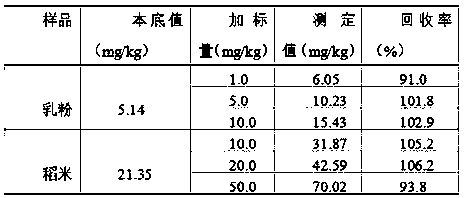

[0027] 1) Sample pretreatment: Weigh 0.5g of food sample containing silicon dioxide, put it in a polytetrafluoroethylene digestion tank, add 8mL of nitric acid and 1mL of hydrogen peroxide, and digest it in a microwave digestion apparatus. The procedure for microwave digestion is Keep at 120°C for 8 minutes, and at 180°C for 15 minutes, with a power of 1600W. After the digestion is complete, transfer the liquid and solid residues in the tank to quantitative filter paper, filter, and wash with water. Put the filter paper and residue into a polytetrafluoroethylene digestion tank, add 8mL nitric acid, 5mL hydrochloric acid, and 2mL hydrofluoric acid for microwave digestion, set the microwave digestion program at 120°C for 10min, and at 150°C for 25min, with a power of 1600W. After digestion, the solution After adding 0.12g of potassium hydroxide to the medium for reaction, transfer the solution to be tested to a 50mL plastic volumetric flask, and do a blank test at the same time; ...

Embodiment 2

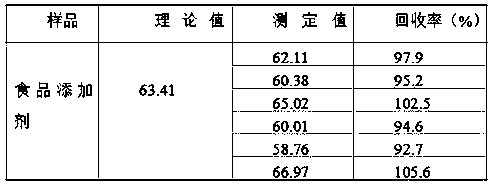

[0036] The difference from Implementation 1 is that the sample selected in this case is a food additive with a known silica content. Other pretreatment and on-machine test steps are the same as those of Embodiment 1. The results of six parallel measurements are shown in Table 2.

[0037] Table 2

[0038]

[0039] The spiked recovery rate of food additives is 92.7%~105.6%, which meets the requirements of GB / T 27404-2008 "Laboratory Quality Control Specifications" for spiked recovery, and the RSD is 4.76%. Silicon has good precision and high accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com