Bactericide used for biofilter filler and preparation method of bactericide

A biofilter and fungicide technology, applied in the direction of chemicals for biological control, botanical equipment and methods, fungicides, etc., can solve problems such as incomplete sterilization, affecting sewage purification effect, and secondary pollution of sewage. Achieve the effects of reducing surface tension, improving extraction efficiency, and simple extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

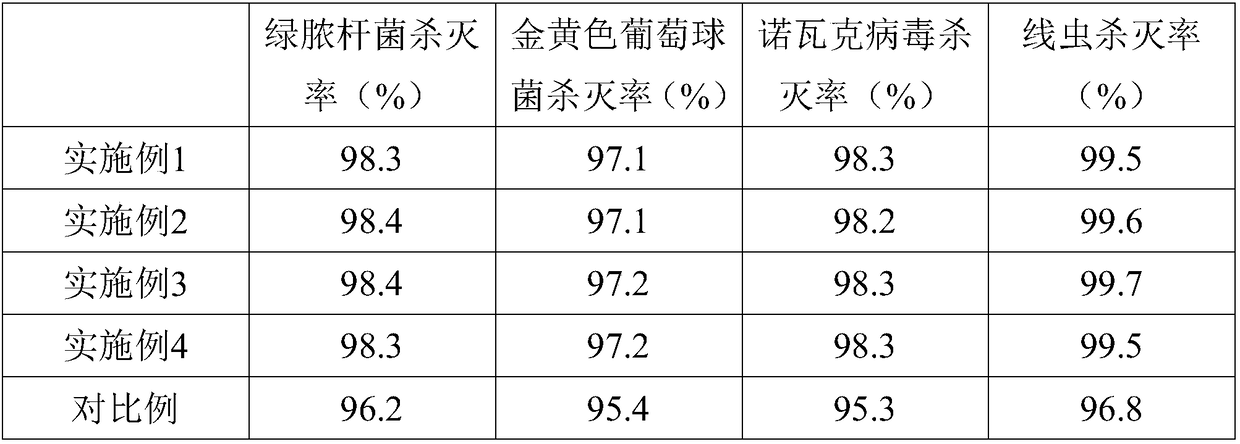

Examples

Embodiment 1

[0023] A bactericide for biological filter filler, which is composed of the following raw materials in parts by weight: 50 parts of sweetgum resin, 30 parts of neem bark, 15 parts of Nepeta nepeta, 30 parts of perilla seed, 15 parts of bile alum, copper hydroxide 12 parts, 4 parts of papain, 1 part of kasugamycin, 15 parts of potassium dichromate, 8 parts of potassium iodate, 18 parts of sodium dodecylbenzenesulfonate, 1 part of trimethoprim, 700 parts of deionized water parts, 100 parts of glycerin.

Embodiment 2

[0025] A bactericide for biological filter filler, which is composed of the following raw materials in parts by weight: 70 parts of sweetgum resin, 40 parts of neem bark, 25 parts of Nepeta nepeta, 50 parts of perilla seed, 35 parts of bile alum, copper hydroxide 15 parts, 6 parts of papain, 2 parts of kasugamycin, 35 parts of potassium dichromate, 10 parts of potassium iodate, 22 parts of sodium dodecylbenzenesulfonate, 2 parts of trimethoprim, 800 parts of deionized water parts, 120 parts of glycerin.

[0026] The preparation method of the described bactericide for biofilter filler, comprises the following steps:

[0027] (1) Mix sweetgum resin, neem bark, Nepeta nepeta and perilla seed evenly, grind them, add 6% mass concentration of sodium hydroxide solution, then put them in a reaction kettle and keep warm at 140°C for 4 hours, and filter after cooling , wash the filter residue to neutral, mix the filter residue and diatomaceous earth evenly, put it into a high-speed mix...

Embodiment 3

[0031] A bactericide for biological filter filler, which is composed of the following raw materials in parts by weight: 60 parts of liquid sweetgum, 35 parts of neem bark, 20 parts of Nepeta nepeta, 40 parts of perilla seed, 25 parts of bile alum, copper hydroxide 13 parts, 5 parts of papain, 1 part of kasugamycin, 25 parts of potassium dichromate, 9 parts of potassium iodate, 20 parts of sodium dodecylbenzenesulfonate, 1 part of trimethoprim, 750 parts of deionized water parts, 110 parts of glycerin.

[0032] The preparation method of the described bactericide for biofilter filler, comprises the following steps:

[0033] (1) Mix sweetgum resin, neem bark, nepeta nepeta and perilla seed evenly, pulverize, add 7% mass concentration of sodium hydroxide solution, then put it in a reaction kettle and keep it warm at 150°C for 5 hours, and filter after cooling , clean the filter residue to neutral, mix the filter residue and diatomaceous earth evenly, put it into a high-speed mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com