Au/Bi24O31Br10 composite photocatalyst and preparation method thereof

A bi24o31br10, composite light technology, applied in the field of photocatalysis, can solve the problems of high preparation conditions, high toxicity of materials, difficult application, etc., and achieve the effects of simple preparation process, improved absorption range, and improved photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

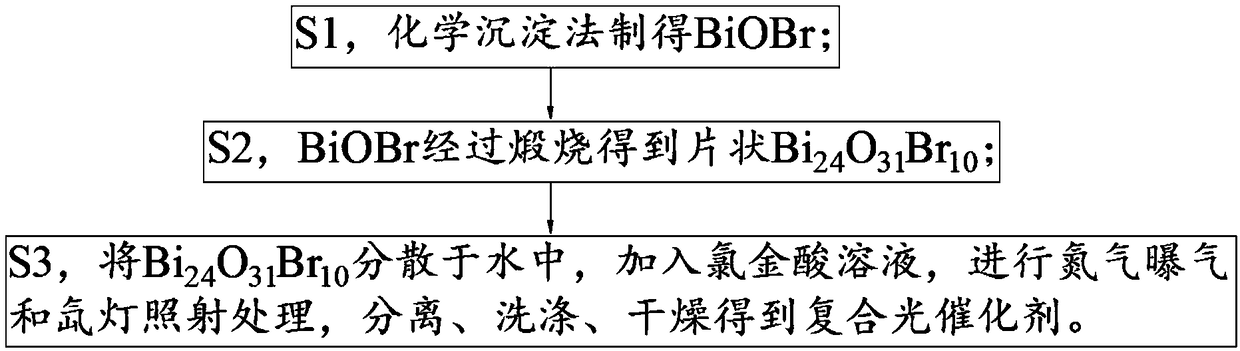

[0024] The embodiment of the present invention provides an Au / Bi 24 o 31 Br 10 The preparation method of composite photocatalyst comprises the following steps:

[0025] S1, BiOBr was prepared by chemical precipitation;

[0026] S2, BiOBr was calcined to obtain flake Bi 24 o 31 Br 10 ;

[0027] S3, will Bi 24 o 31 Br 10 Disperse in water, add chloroauric acid solution, and then carry out nitrogen aeration and xenon lamp irradiation treatment to obtain a suspension, which is separated, washed and dried to obtain Au / Bi 24 o 31 Br 10 composite photocatalyst.

[0028] Semiconductor Bi 24 o 31 Br 10 is a photocatalyst responsive to visible light, but due to the Bi 24 o 31 Br 10 The specific surface area of the material is small, there are many defects, and the recombination rate of photogenerated carriers inside the material is high. By using Au nanoparticles with flake Bi 24 o 31 Br 10 For recombination, the Au particles are deposited on the sheet-like Bi by...

Embodiment 1

[0049] Embodiment 1 (0.5Au-Bi 24 o 31 Br 10 )

[0050] A kind of Au / Bi that the present embodiment provides 24 o 31 Br 10 Composite photocatalyst, it is made according to the following steps:

[0051] 1) Bi 24 o 31 Br 10 preparation of

[0052] 10mmol of Bi(NO 3 ) 3 ·H 2 O was dissolved in 100mL ethylene glycol, ultrasonicated for 30min, and stirred for 12h to obtain solution A;

[0053] Dissolve 10 mmol of KBr in 50 mL of ethylene glycol, sonicate for 30 min, and stir for 12 h to obtain solution B;

[0054] Solution B was added dropwise to solution A, stirred for 1 h, and then heated in a water bath at 85° C. for 3.5 h. Then quickly dropwise added to 150mL ethanol-water solution (v / v=1:2) to obtain a white precipitate C, which was washed three times with ultrapure water and absolute ethanol, and dried at 70°C for 5h to obtain a white powder D: Transfer the powder D to a muffle furnace, heat it up to 600°C at a heating rate of 5°C / min, and keep it for 2h to obta...

Embodiment 2

[0057] Embodiment 2 (1Au-Bi 24 o 31 Br 10 )

[0058] A kind of Au / Bi that the present embodiment provides 24 o 31 Br 10 Composite photocatalyst, the difference with embodiment 1 is: 2) Au / Bi 24 o 31 Br 10 For the preparation, add 1.214 mL of 10 mM HAuCl 4 Solution (HAuCl 4 is 0.005g).

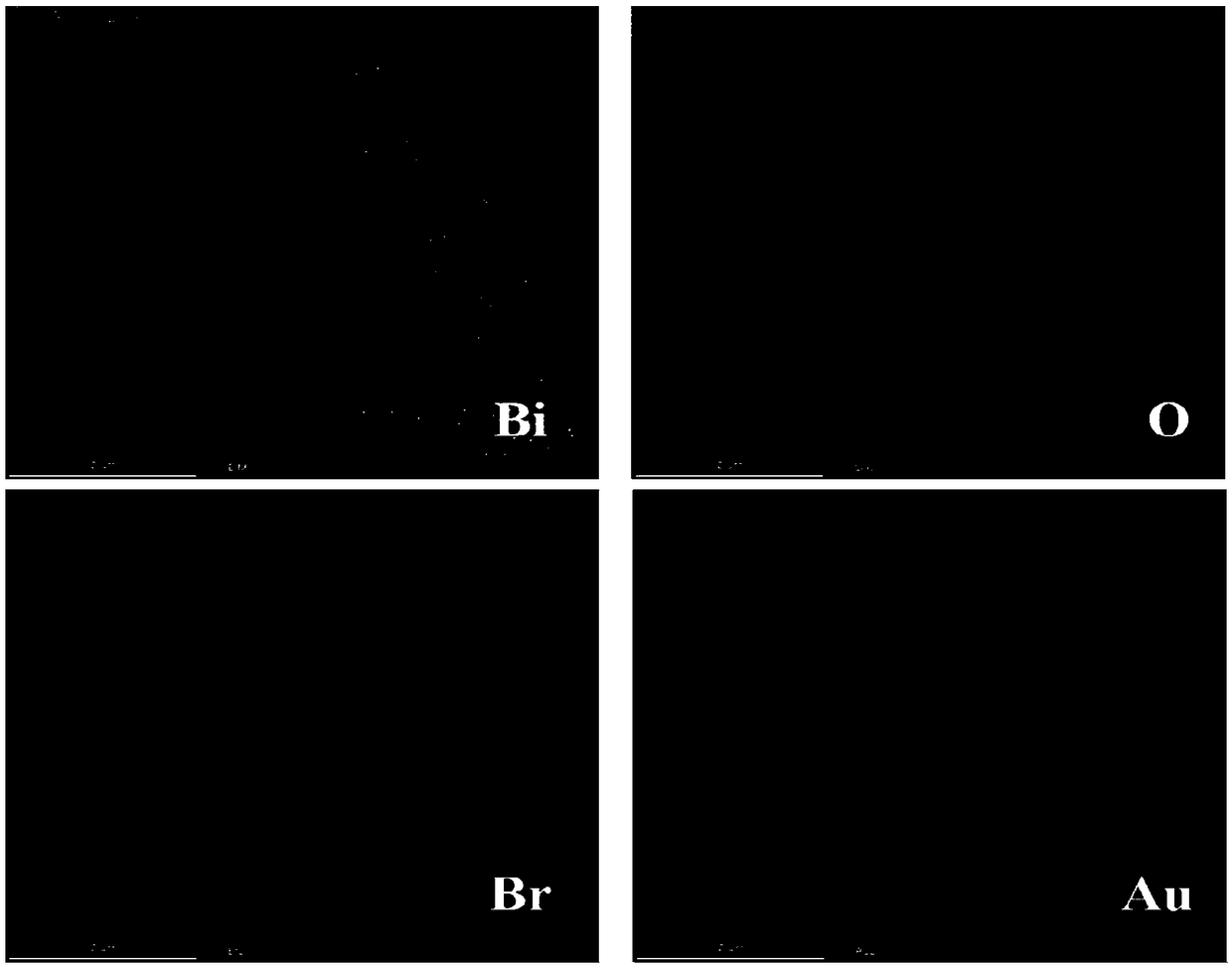

[0059] Such as figure 2 Shown is the prepared 1Au-Bi 24 o 31 Br 10 The scanning electron microscope image, it can be seen that Au particles are loaded on the sheet-like Bi 24 o 31 Br 10 and the Au particles are evenly distributed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com