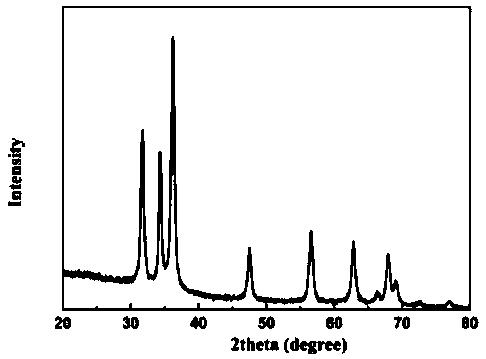

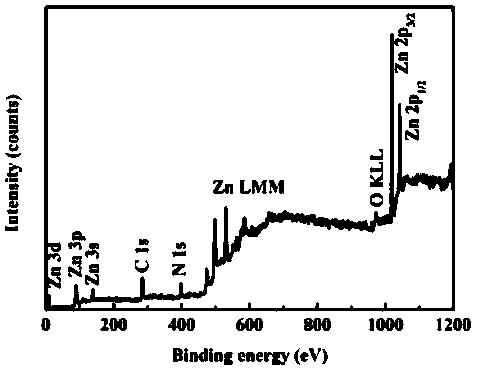

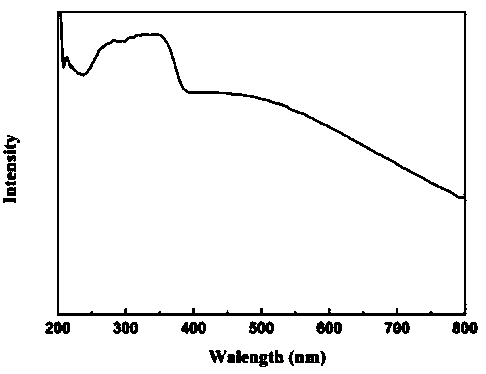

Black zinc oxide and quick preparation method thereof

A zinc oxide, black technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem that the proportion of ultraviolet light is less than 5%, and achieve good dispersion, low cost, The effect of strong light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of quick preparation method of black zinc oxide, comprises the following steps:

[0022] (1) Weigh 2.9g of zinc nitrate solid, then mix and grind the weighed zinc nitrate solid with 0.6g of urea; add 0.2g of citric acid as a foaming agent during the grinding process, add two drops of glycerin, and grind The precursor can be prepared after forming a slurry;

[0023] (2) Put the precursor prepared in step (1) into the preheated muffle furnace, where the preheated temperature in the muffle furnace is 600°C, and take it out of the crucible after calcination for 18 minutes, namely Available in black zinc oxide.

Embodiment 2

[0025] A kind of quick preparation method of black zinc oxide, comprises the following steps:

[0026] (1) Weigh 1.5g of zinc nitrate solid, then mix and grind the weighed zinc nitrate solid with 2.9g of urea; add 0.6g of citric acid as a foaming agent during the grinding process, add two drops of glycerin, and grind The precursor can be prepared after forming a slurry;

[0027] (2) Put the precursor prepared in step (1) into the preheated muffle furnace, where the preheated temperature in the muffle furnace is 800°C, and take it out of the crucible after calcination for 10 minutes, namely Available in black zinc oxide.

Embodiment 3

[0029] A kind of quick preparation method of black zinc oxide, comprises the following steps:

[0030] (1) Weigh 2.5g of zinc sulfate solid, then mix and grind the weighed zinc sulfate solid with 0.8g of urea; add 0.5g of citric acid as a foaming agent during the grinding process, add two drops of glycerin, and grind The precursor can be prepared after forming a slurry;

[0031] (2) Put the precursor prepared in step (1) into the preheated muffle furnace, where the preheated temperature in the muffle furnace is 900°C, and take it out of the crucible after calcination for 20 seconds, namely Available in black zinc oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com