A kind of preparation method of hydrocracking catalyst with high light oil selectivity

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of low octane number of naphtha

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Preparation of Y molecular sieve Z1

[0033] Prepare 2000mL of 3wt% dilute nitric acid solution, add 500g of Y molecular sieve Z0 to it, stir vigorously at 50°C for 4h, settle for 2-3h, pour out most of the upper liquid, centrifuge the remaining solid and a small amount of liquid, and centrifuge the solid Add 250mL deionized water, stir and wash, and centrifuge. Repeat centrifugation and washing for 3 times, and finally the molecular sieve solid obtained by centrifugation is first dried at 150°C for 8 hours, and then calcined at 500°C for 4 hours in an air atmosphere to obtain acid-treated molecular sieve Z1.

Embodiment 2

[0034] Embodiment 2: Preparation of Y molecular sieve Z2

[0035] Prepare 1000mL, 1mol / L ethylenediaminetetraacetic acid (EDTA) ethanol solution, add 200g Y molecular sieve Z0 to it, stir vigorously at room temperature for 4 hours, settle for 2-3 hours, pour out most of the upper liquid, and carry out the remaining solid and a small amount of liquid After centrifugation, the centrifuged solid was added to 200 mL of ethanol, stirred, washed, and centrifuged. Repeat centrifugation and washing for 3 times, and finally the molecular sieve solid obtained by centrifugation is dried in a vacuum oven at 80°C for 6h, and then calcined at 500°C for 4h in an air atmosphere to obtain the treated molecular sieve Z2.

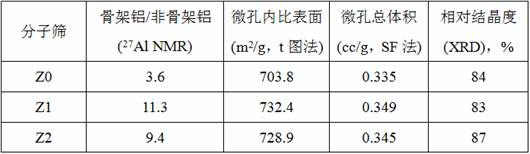

[0036] The properties of commercial Y molecular sieve Z0 and Y molecular sieves Z1 and Z2 prepared in Examples 1 and 2 are compared in Table 1.

[0037] Table 1 Performance comparison of different molecular sieves

[0038]

[0039] Depend on 27According to the character...

Embodiment 3

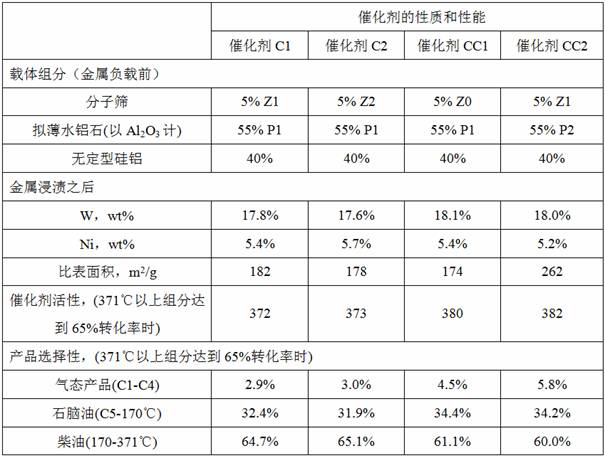

[0040] Example 3: Preparation of hydrocracking catalyst C1 (Z1+P1 (acid gel index 90%))

[0041] Weigh 110 g of pseudo-boehmite P1 (dry basis, unless otherwise specified, all weights of the following raw materials are dry basis), 80 g of imported amorphous silica-alumina, and 10 g of molecular sieve Z1, and fully mix the three solid powders Finally, add the pre-prepared dilute nitric acid solution (3.3g, 67wt% concentrated nitric acid diluted with 200 g deionized water), knead vigorously for 15 minutes, extrude through a 2.5mm orifice plate, and dry at 120°C for 6h. Calcined in air at 500°C for 4h to obtain the catalyst carrier. Then impregnate the carrier with a mixed aqueous solution of ammonium metatungstate and nickel nitrate in equal volume to load 18% W and 5.4% Ni (theoretical weight), and then dry it at 120°C for 4 hours, then dry it at 500°C in an air atmosphere Calcined for 4h, the resulting catalyst was marked as C1.

[0042] Implementation 4: Preparation of hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com