Carbon-nitrogen material and preparation method thereof, lithium-sulfur battery positive electrode material and lithium-sulfur battery containing it

A carbon-nitrogen material and catalyst technology, applied in the field of new energy batteries, can solve the problems of poor cycle stability of lithium-sulfur batteries, and achieve the effects of improving cycle stability, reducing the amount of dissolution, and reducing the chance of being dissolved in the electrolyte

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] On the one hand, the invention provides a kind of preparation method of carbon-nitrogen material, comprises the following steps:

[0033] The mixture of the catalyst and melamine is placed in an inert atmosphere for sintering to obtain the carbon-nitrogen material.

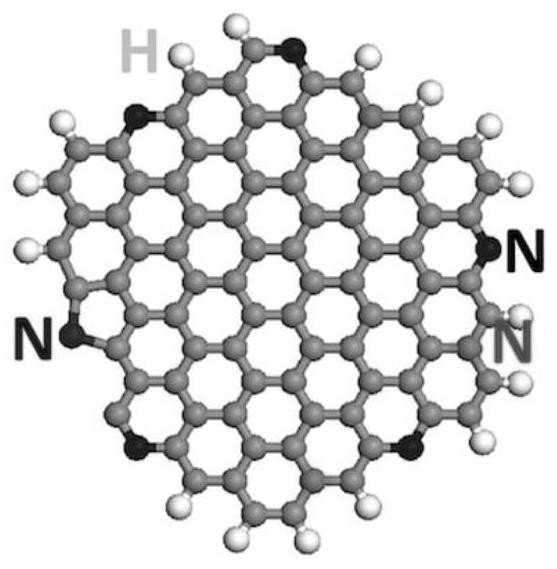

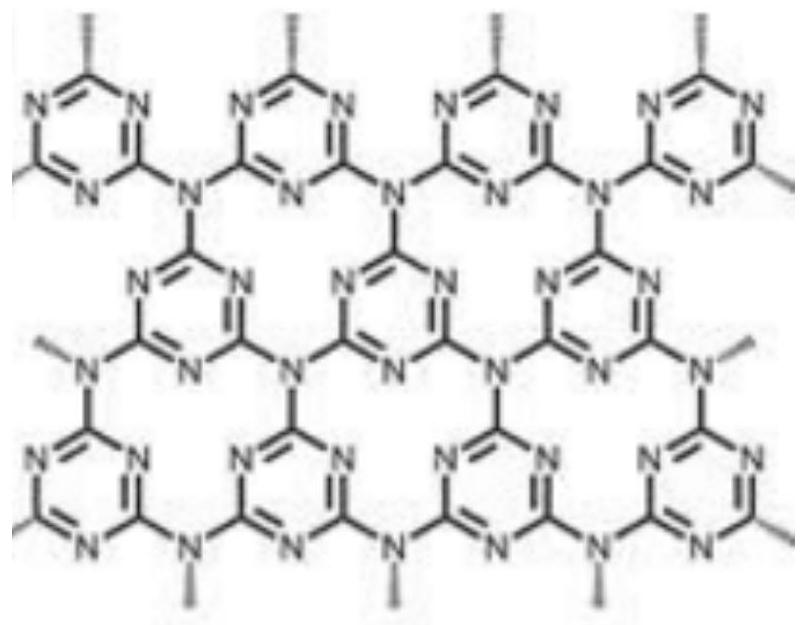

[0034] The preparation method of the carbon-nitrogen material provided by the present invention uses melamine as the reaction raw material, and rapidly synthesizes the carbon-nitrogen material (such as carbon-nitrogen nanotube) through high-temperature sintering under the action of a catalyst (such as nickel chloride). Owing to adopting melamine as raw material in this preparation method, the atomic arrangement structure diagram of the carbon-nitrogen material obtained after sintering is as follows figure 2 As shown, will figure 2 and figure 1 Compared with the schematic diagram of the structure, it can also be seen that the nitrogen content is significantly increased.

[0035] In addition, in the prep...

Embodiment 1

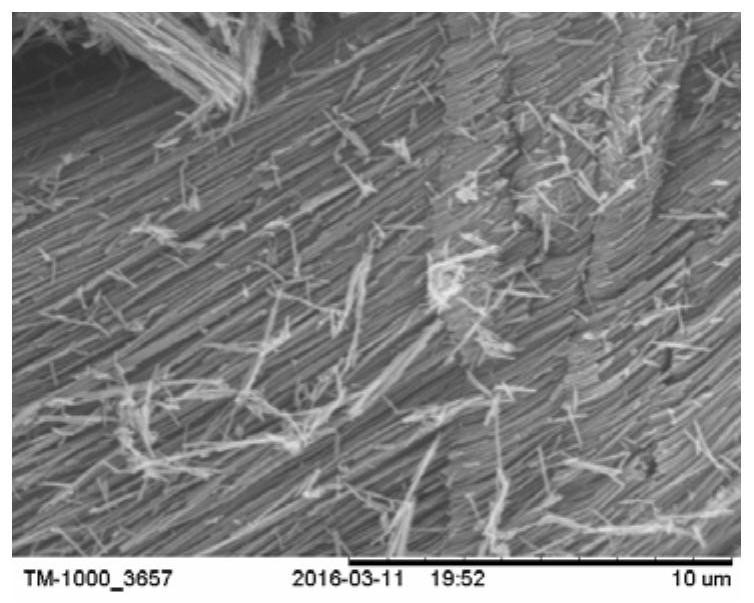

[0058] This embodiment is a carbon-nitrogen nanotube. The preparation method of the carbon-nitrogen nanotube is: uniformly mix nickel chloride and melamine with a mass ratio of 2:8 through high-energy ball milling, and then heat to 600 °C under an argon atmosphere. ℃, keep warm for 4h, and obtain carbon-nitrogen nanotubes with a diameter of about 100nm, whose structure is as follows image 3 shown.

Embodiment 2

[0060] This embodiment is a positive electrode material for a lithium-sulfur battery, including sulfur powder and carbon-nitrogen nanotubes in Embodiment 1, wherein the mass ratio of sulfur powder to carbon-nitrogen nanotubes is 70:30.

[0061] The preparation method of the positive electrode material of the lithium-sulfur battery is as follows: high-energy ball milling of sulfur powder with a mass ratio of 70:30 and carbon-nitrogen nanotubes for 2 hours, then putting the prepared powder into a 200ml reaction kettle, heating to 155°C, and keeping it warm After 12 hours, the cathode material for lithium-sulfur battery was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com