Combined pretreatment device and pretreatment method for semi-coke wastewater

A semi-coke wastewater and combined device technology, applied in the field of water treatment, can solve the problems of long multi-stage filtration process and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

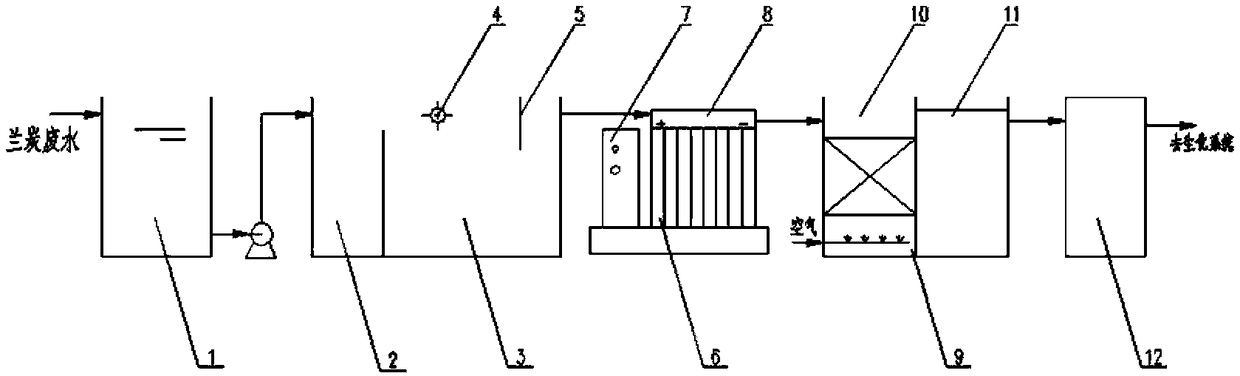

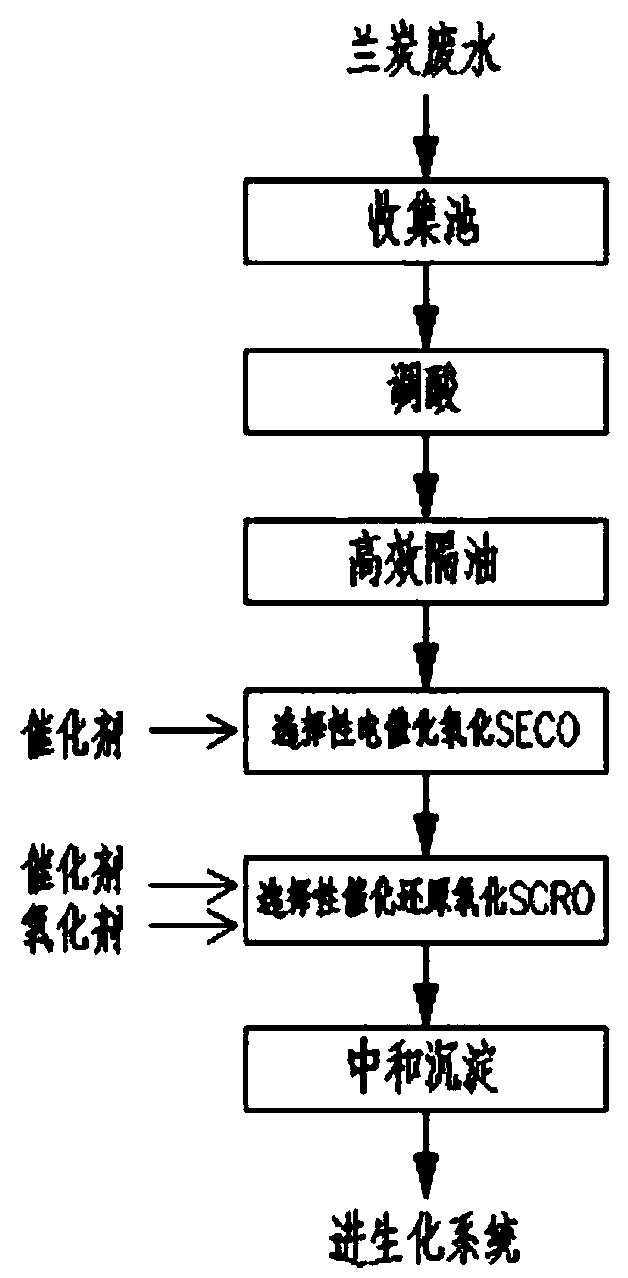

[0030] Embodiment 1: as figure 1 As shown, the combined pretreatment device for semi-coke wastewater includes a collection pool 1, an acid adjustment pool 2, a high-efficiency oil separation device 3, a selective catalytic oxidation device (SECO) 6, and a selective catalytic reduction oxidation reactor (SCRO) 9 And neutralize the sedimentation tank 12, the collection tank 1 is connected with the acid adjustment tank 2, the acid adjustment tank 2 is in communication with the high-efficiency oil separation device 3, and the high-efficiency oil separation device 3 is connected with the selected The selective catalytic oxidation device (SECO) 6 is connected, and the selective catalytic oxidation device (SECO) 6 is connected with the selective catalytic reduction oxidation reactor (SCRO) 9, and the selective catalytic reduction oxidation reactor (SCRO) ) 9 is connected with the neutralization sedimentation tank, and the selective catalytic reduction oxidation reactor (SCRO) 9 inclu...

Embodiment 2

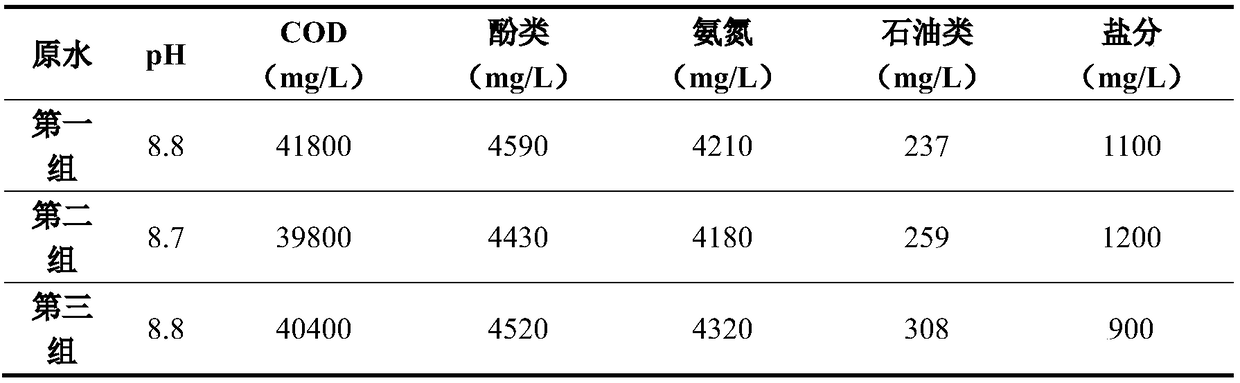

[0038] Embodiment 2: Adopt the device and the method in implementing 1, take the blue charcoal waste water of three groups of adjustment tanks that a certain coking plant in Shaanxi got as an example, the waste water quality index is as follows table 1:

[0039] Table 1 The water quality indicators before the treatment of the three groups of blue carbon wastewater

[0040]

[0041] The processing method includes the following steps:

[0042] (1) First of all, after the semi-coke wastewater is discharged into the collection pool 1, it is pumped to the acid adjustment pool 2 for pH adjustment, and the pH value of the semi-coke wastewater is adjusted to 1 to 2 by using hydrochloric acid. A large amount of precipitation, rapid stratification;

[0043] (2) Separating the upper layer floating oil and the bottom heavy oil in the waste water through the high-efficiency oil separation device 3;

[0044] (3) The clear water separated by oil separation enters the selective catalytic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com