Extracting method of oyster peptides

An extraction method and oyster peptide technology, applied in the field of oyster peptide extraction, can solve the problems of poor sensory acceptance, heavy peptide smell, and limited application, and achieve the goal of increasing contact opportunities, improving yield and quality, and uniform molecular weight distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

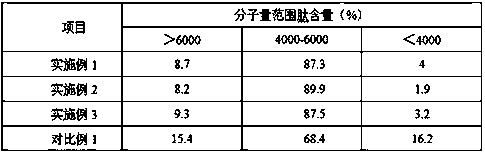

[0018] A method for extracting oyster peptides, removing viscera from oyster meat and homogenizing it, first adding active dry yeast and arabinose to remove the fishy smell, then adding β-cyclodextrin for treatment, adjusting the pH value of the oyster meat homogenate after removing the fishy smell, adding compound The protease is subjected to constant temperature enzymolysis, and after the enzymolysis is completed, the enzyme is inactivated, the supernatant of centrifugation is filtered, and freeze-dried to obtain the oyster peptide. The preparation method has the advantages of low investment, simple operation, good protein degradation effect, high oyster peptide yield, and high sensory acceptance, and is easy to produce on an industrial scale. The molecular weight distribution of the obtained oyster peptide is uniform, and the molecular weight range is 4000-6000. Oyster peptide content is greater than 87%, which has good application value and market potential.

[0019] The s...

Embodiment 2

[0027] A method for extracting oyster peptides. Homogenize oyster meat after removing internal organs. The weight ratio of oyster meat and water in the homogenate is 1:8. Active dry yeast and arabinose are added to the homogenate, wherein the addition of active dry yeast The amount is 1.0% of the weight of oyster meat, and the amount of arabinose added is 0.2% of the weight of oyster meat. It is deodorized at 40°C for 25 minutes, and then β-cyclodextrin with 6% of the weight of oyster meat is added. Under the condition of 350MPa, the ultra-high pressure deodorization treatment for 15 minutes obtained the deodorized oyster meat homogenate, adjusted the pH of the deodorized oyster homogenate to 8.0, added the compound protease according to the enzyme amount of 3.5%, and then added 2.4% by weight of the compound protease Sodium octadecanoate and 0.4% tetrabutylammonium bromide, and then enzymatically hydrolyzed at 35°C for 10 hours to obtain an enzymolyzed solution, and then ultra...

Embodiment 3

[0029] A method for extracting oyster peptides. The oyster meat is removed from viscera and then homogenized. The weight ratio of oyster meat and water in the homogenate is 1:10. Active dry yeast and arabinose are added to the homogenate, wherein the addition of active dry yeast The amount is 0.8% of the weight of oyster meat, and the amount of arabinose is 0.3% of the weight of oyster meat. It is deodorized at 38°C for 30 minutes, and then β-cyclodextrin with 5% of the weight of oyster meat is added. Under the condition of 300MPa, the ultra-high pressure deodorization treatment for 20 minutes is used to obtain the deodorized oyster meat homogenate, adjust the pH of the deodorized oyster meat homogenate to 7.5, add the compound protease according to the enzyme amount of 4%, and then add 2% of the weight of the compound protease Sodium octadecanoate and 0.5% tetrabutylammonium bromide, and then enzymolyzed at 30°C for 12 hours to obtain an enzymolyzed solution, and then ultrafil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com