A kind of anti-blue light and anti-infrared composition and its application

A composition and anti-blue light technology, applied in the field of anti-blue light and anti-infrared compositions, can solve problems such as the inability to resist blue light to skin damage, and achieve the effects of easy promotion and application, simple and efficient preparation method, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

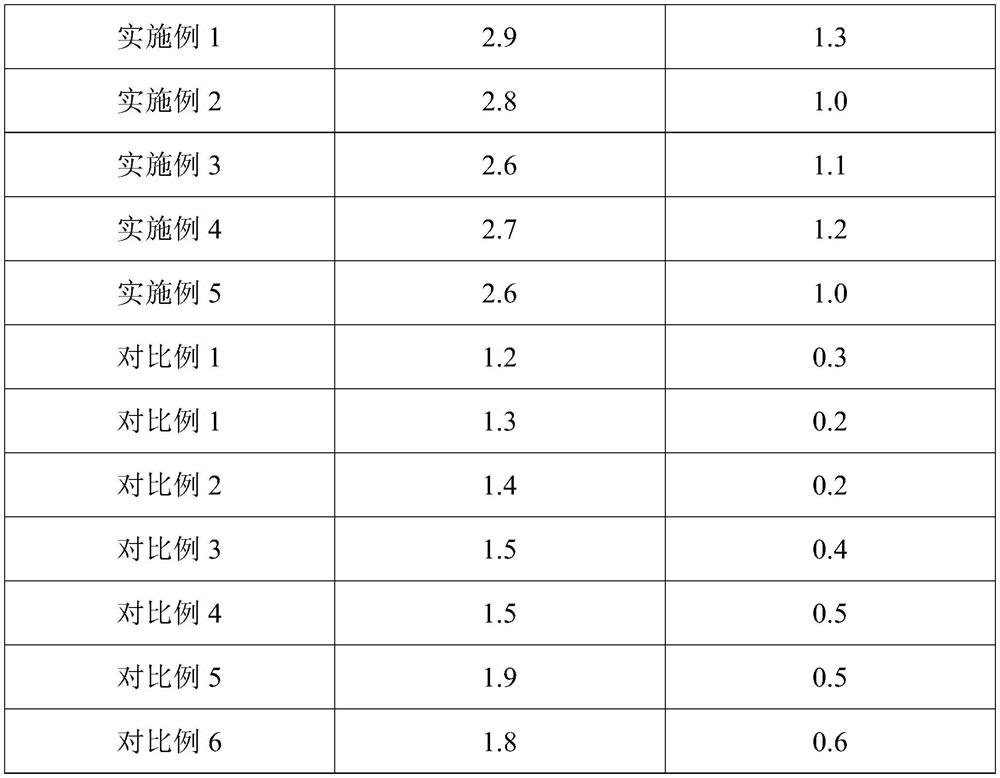

Examples

Embodiment 1

[0044] (1) Add the water phase components into the water phase pot, heat to 65°C, stir, dissolve and keep warm for 30 minutes, then cool down to 35°C for use; the water phase includes: water (36.23%), glycerin (6.0%), butyl Diol (4.0%), Betaine (2.0%), Sodium Chloride (1.0%), Methylparaben (0.2%) and Disodium EDTA (0.05%);

[0045] (2) Add the oil phase components into the emulsification pot and stir evenly, heat to 65°C, stir, dissolve and keep warm for 30 minutes, then cool down to 35°C for use;

[0046] The oil phase includes: Cyclopentasiloxane (12.0%), CI 77891 (8.0%), Butylene Glycol Dicaprylic / Dicaprate (5.0%), Caprylyl Methicone (3.0%), Dimethicone (1.5%), Lauryl PEG-9 Dimethicone Dimethicone (2.0%), PEG-10 Dimethicone Oxane (2.5%), Acrylates / Dimethicone Copolymer (5.0%), Methyl Methacrylate Crosspolymer (2.0%), Vinyl Dimethicone / Dimethicone Methylsiloxane Silsesquioxane Crosspolymer (1.0%), Magnesium Stearate (0.5%), Aluminum Hydroxide (0.01%), Triethoxycaprylylsila...

Embodiment 2

[0049] (1) Add the water phase components into the water phase pot, heat to 60°C, stir, dissolve and keep warm for 30 minutes, then cool down to 30°C for use; the water phase includes: water (39.73%), glycerin (6.0%), butyl Diol (4.0%), Betaine (2.0%), Sodium Chloride (1.0%), Methylparaben (0.2%) and Disodium EDTA (0.05%);

[0050] (2) Add the oil phase components into the emulsification pot and stir evenly, heat to 60°C, stir, dissolve and keep warm for 30 minutes, then cool down to 30°C for use; the oil phase includes: cyclopentasiloxane (12.0% ), CI 77891 (8.0%), Butylene Glycol Dicaprylate / Dicaprate (5.0%), Capryl Methicone (3.0%), Dimethicone (1.5%), Lauryl Base PEG-9 Dimethicone Ethyl Dimethicone (2.0%), PEG-10 Dimethicone (2.5%), Acrylates / Dimethicone Copolymer (5.0%), Methyl Methacrylate Crosspolymer (2.0%), Vinyl Dimethicone / Methicone Silsesquioxane Crosspolymer (1.0%) , magnesium stearate (0.5%), aluminum hydroxide (0.01%), triethoxyoctylsilane (0.05%), cyclohexasi...

Embodiment 3

[0053] (1) Add the water phase components into the water phase pot, heat to 70°C, stir, dissolve and keep warm for 30 minutes, then cool down to 38°C for use; the water phase includes: water (32.23%), glycerin (6.0%), butyl Diol (4.0%), Betaine (2.0%), Sodium Chloride (1.0%), Methylparaben (0.2%) and Disodium EDTA (0.05%);

[0054] (2) Add the oil phase components into the emulsification pot and stir evenly, heat to 70°C, stir, dissolve and keep warm for 30 minutes, then cool down to 38°C for use; the oil phase includes: cyclopentasiloxane (12.0% ), CI 77891 (8.0%), Butylene Glycol Dicaprylate / Dicaprate (5.0%), Capryl Methicone (3.0%), Dimethicone (1.5%), Lauryl Base PEG-9 Dimethicone Ethyl Dimethicone (2.0%), PEG-10 Dimethicone (2.5%), Acrylates / Dimethicone Copolymer (5.0%), Methyl Methacrylate Crosspolymer (2.0%), Vinyl Dimethicone / Methicone Silsesquioxane Crosspolymer (1.0%) , magnesium stearate (0.5%), aluminum hydroxide (0.01%), triethoxyoctylsilane (0.05%), cyclohexasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com