Bentazone and florasulam synergistic weeding composition and dispersible oil suspending agent thereof

A technology of bioxsulam and a herbicidal composition, which is applied in the field of pesticides, can solve the problems of compound application of bentazone and bioxsulam, etc., and achieves delaying weed drug resistance, good quick-acting performance and the like. Long-lasting, pollution-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

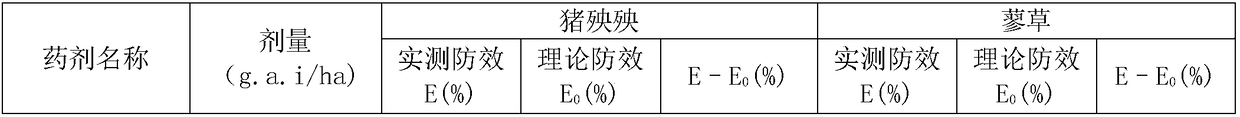

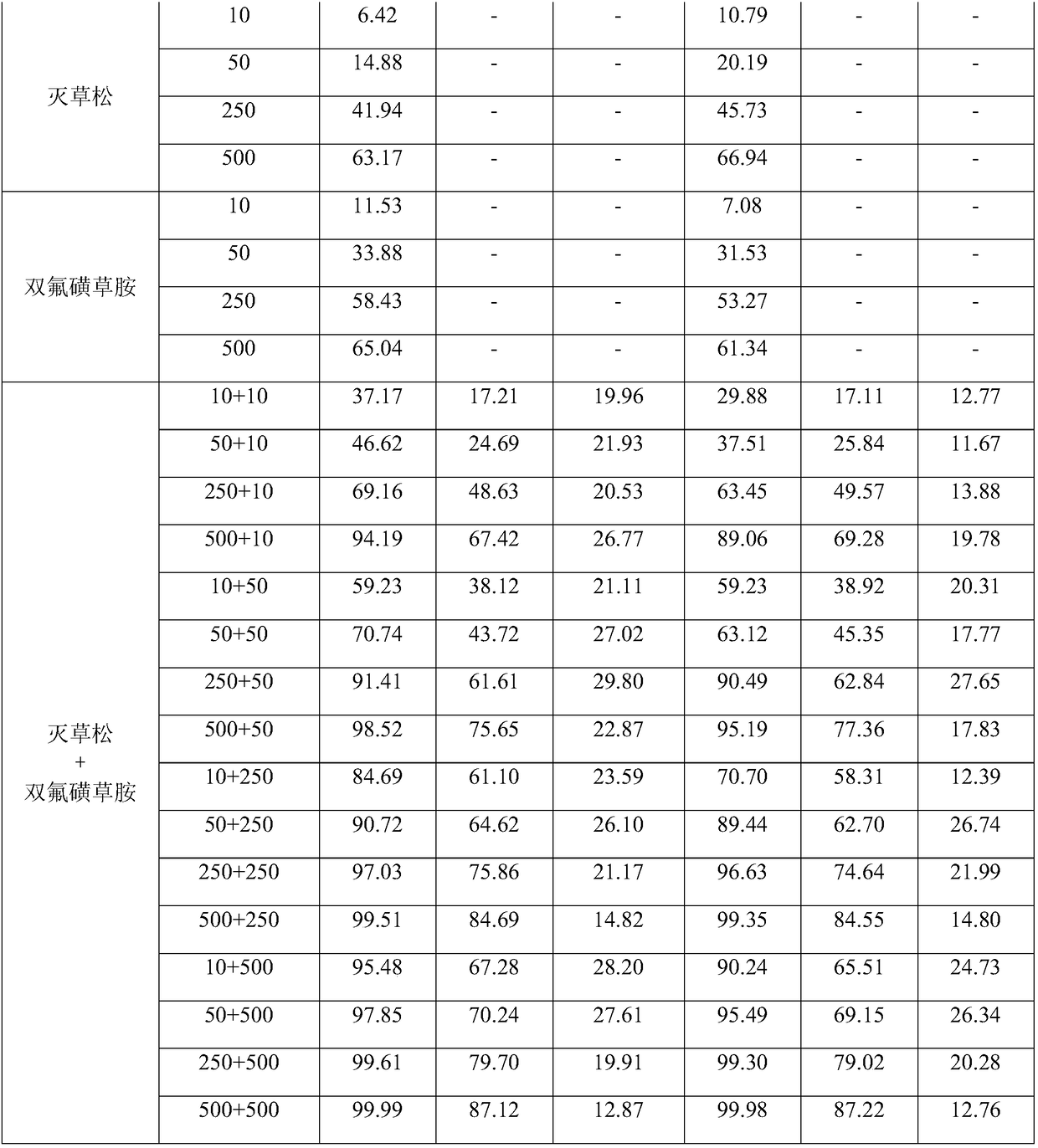

Method used

Image

Examples

Embodiment 1

[0046] Weigh bentazone (1%), florasulam 40%, emulsifier AEO-9 (5%), S-20 (10%), Nongru 500# (3%) dispersant NNO (7%) ), wetting agent naphthalenesulfonate (1%), stabilizer nitrogen methyl pyrrolidone (3%), thickener bentonite (3%), silicone defoamer (0.03%), synergist imino di Tetrasodium succinate (5%) and soybean oil make up to 100% by weight. The above raw materials were mixed and dispersed by high-speed shearing for 30 minutes, and sand-milled for 2-3 hours with a sand mill until the D90 of the granules was less than 10 μm, and a 41% bentazone-flusulam synergistic dispersible oil suspension was prepared.

Embodiment 2

[0048] Weigh bentazone (5%), florasulam (35%), emulsifier NP-7 (8%), BY-140 (10%), dispersant sodium pyrophosphate (10%), wetting Agent alkyl sulfonate (5%), stabilizer epichlorohydrin (2%), thickener xanthan gum (1%), silicone defoamer (0.03%), tetrasodium iminodisuccinate (10%), palm oil make up to 100% weight part. The above raw materials were mixed and dispersed by high-speed shearing for 30 minutes, and then sand-milled with a sand mill for 2-3 hours until the D90 of the granules was less than 10 μm, and a 40% bentazone-flusulam synergistic dispersible oil suspension was prepared.

Embodiment 3

[0050] Weigh bentazone (10%), florasulam (40%), emulsifier OP-10 (5%), agricultural milk 500# (12%), dispersant maleic acid-acrylic acid (8%) , wetting agent alkylphenol polyoxyethylene ether phosphate (3%), stabilizer epoxy soybean oil (0.5%), thickener magnesium aluminum silicate (0.5%), xanthan gum (1%), poly Ether defoamer (1%), tetrasodium iminodisuccinate (3%), and corn oil are added to 100% by weight. The above raw materials are mixed and dispersed by high-speed shearing for 30 minutes, and sand-milled with a sand mill for 2-3 hours until the D90 of the granules is less than 10 μm, and a 50% bentazone-flusulam synergistic dispersible oil suspension is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com