Anti-radiation isolation cream and preparation method thereof

A barrier cream and anti-radiation technology, which is applied in the direction of pharmaceutical formulas, cosmetic preparations, dressing preparations, etc., can solve the problem of weakening the skin care effect of barrier cream, and achieve the effect of high purity, safety, and strong antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 water-soluble fullerene

[0031] (1) Fullerene C 60 The powder is added to the jet milling machine, and the jet mill is carried out under the protection of high-purity inert gas. The fine powder that has been fully ground passes through the gap of the sorting wheel with the airflow, while the powder that has not been fully ground cannot pass through, and the process continues Jet mill until the particle size of the powder is 0.2-1 μm, and collect the fullerene C 60 ultrafine powder;

[0032] (2) to fullerene C 60 Add deionized water to the ultrafine powder, in which fullerene C 60 The mass ratio of ultra-fine powder and water is 1:100000, and the power is 200W, the temperature is 60 ℃ under the conditions of ultrasonic treatment for 60min, cooled to room temperature, adding acetylglucosamine, wherein, acetylglucosamine and fullerene C 60 The mass ratio of the ultrafine powder is 1:9, and the water-soluble fullerene solution is obtaine...

Embodiment 2

[0034] The preparation of embodiment 2 water-soluble fullerenes

[0035] (1) Fullerene C 60 The powder is added to the jet milling machine, and the jet mill is carried out under the protection of high-purity inert gas. The fine powder that has been fully ground passes through the gap of the sorting wheel with the airflow, while the powder that has not been fully ground cannot pass through, and the process continues Jet mill until the particle size of the powder is 0.2-1 μm, and collect the fullerene C 60 ultrafine powder;

[0036] (2) to fullerene C 60 Add deionized water to the ultrafine powder, in which fullerene C 60 The mass ratio of ultrafine powder to water is 1:10000, ultrasonic treatment for 120min under the conditions of power of 100W and temperature of 50°C, cooling to room temperature, adding acetylglucosamine, wherein, acetylglucosamine and fullerene C 60 The mass ratio of the ultrafine powder is 1:6, and the water-soluble fullerene solution is obtained by ultr...

Embodiment 3

[0043] The preparation of embodiment 3 anti-radiation segregation cream

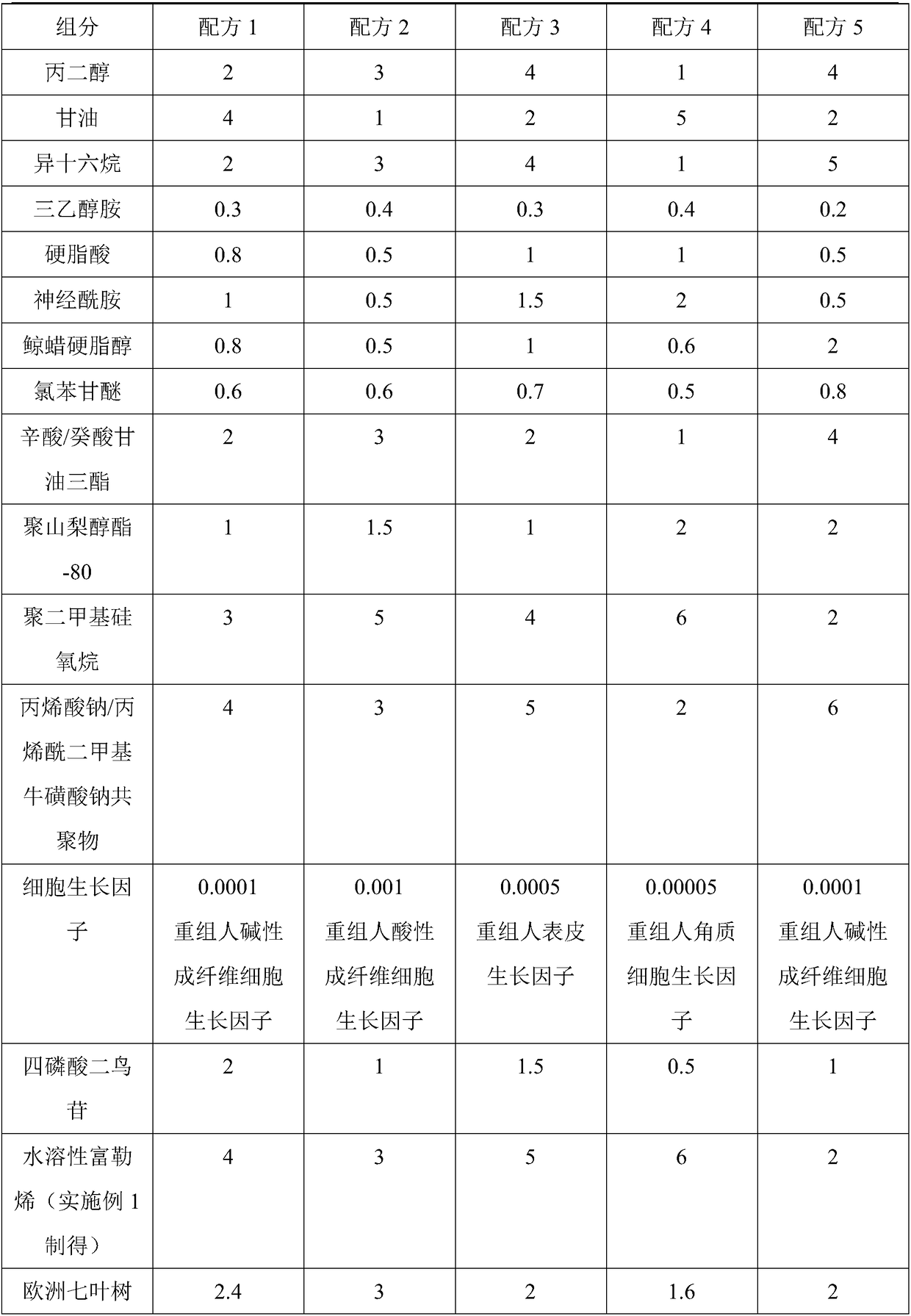

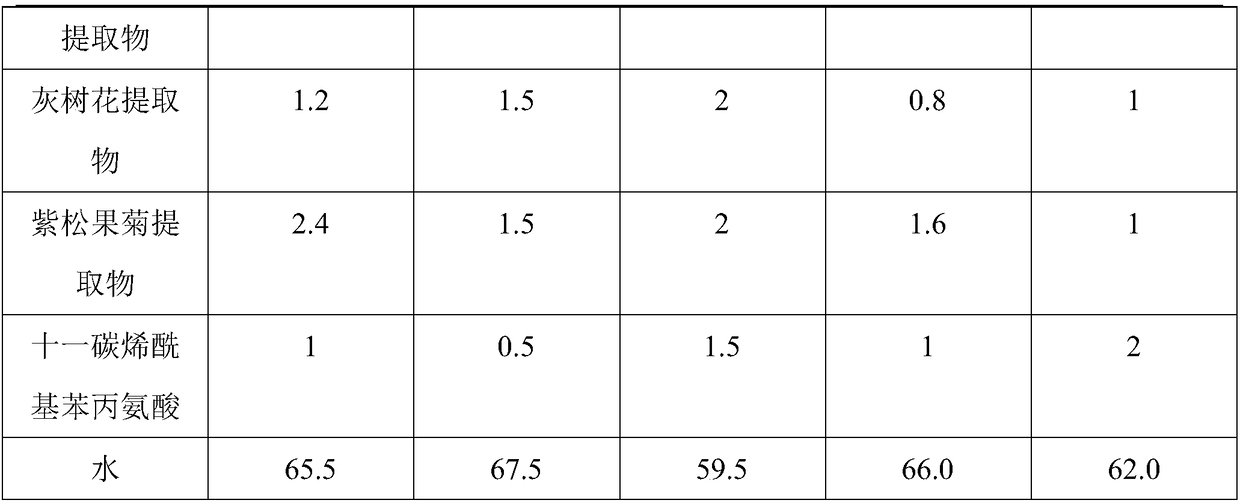

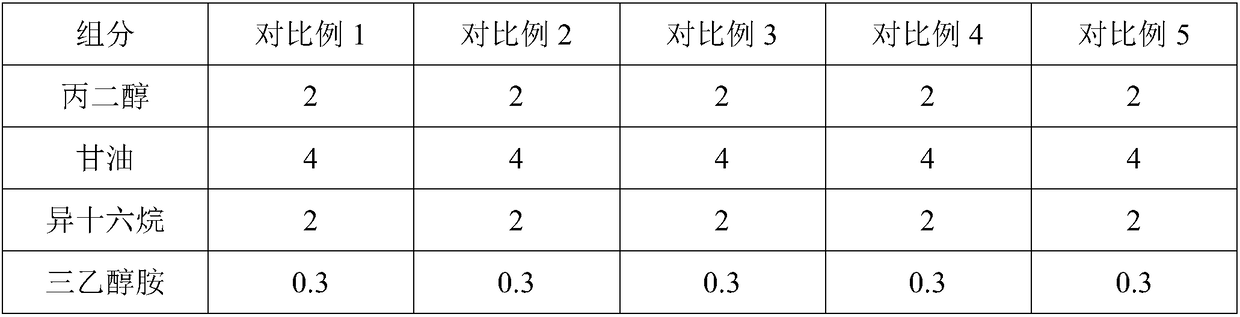

[0044] The present embodiment anti-radiation segregation frost, by mass percentage, comprises the component shown in following table 1:

[0045] The formula composition of table 1 anti-radiation segregation cream

[0046]

[0047]

[0048] Preparation steps:

[0049] (1) Add water, propylene glycol, glycerin, triethanolamine, ceramide, sodium acrylate / sodium acryloyldimethyltaurate copolymer into the emulsification pot, heat up to 80°C and stir until completely dissolved to obtain material A;

[0050] (2) Add isohexadecane, stearic acid, cetearyl alcohol, caprylic acid / capric triglyceride, polysorbate-80, polydimethylsiloxane into the oil pan, heat up to 80 °C and stirred until completely dissolved to obtain material B;

[0051] (3) Pump the material B into the material A, stir evenly, turn on homogenization, stir at constant temperature, and cool;

[0052] (4) Cool down to 40°C, add chlorphene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com