Novel application of manganese nodule and preparation method of layered intercalated titanium dioxide composite material

A technology of titanium dioxide and composite materials, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc. reduce the problem, achieve the effect of changing the characteristics of the exposed crystal plane, improving the adsorption and degradation ability, and improving the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

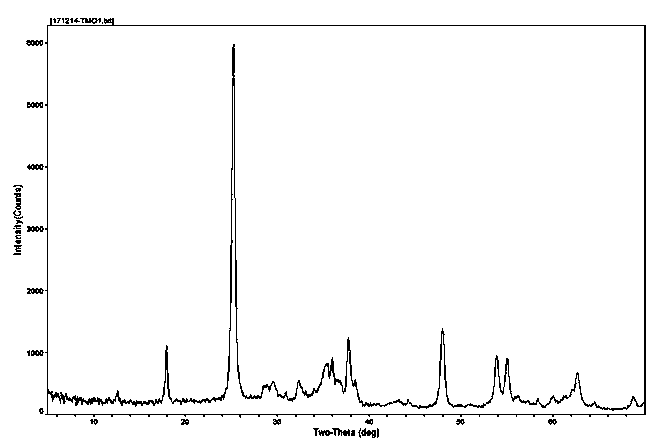

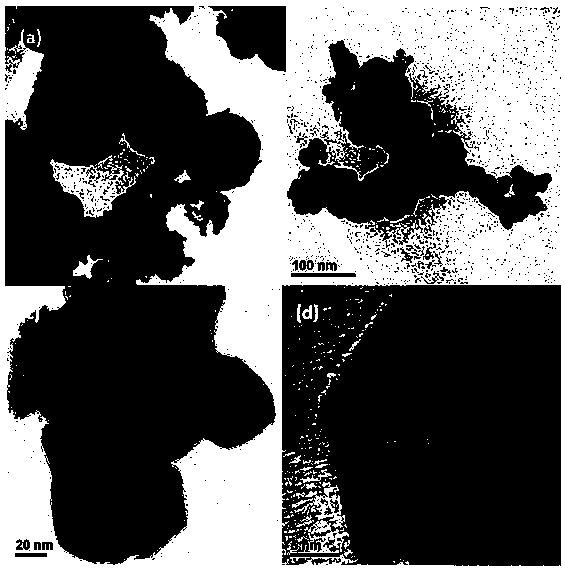

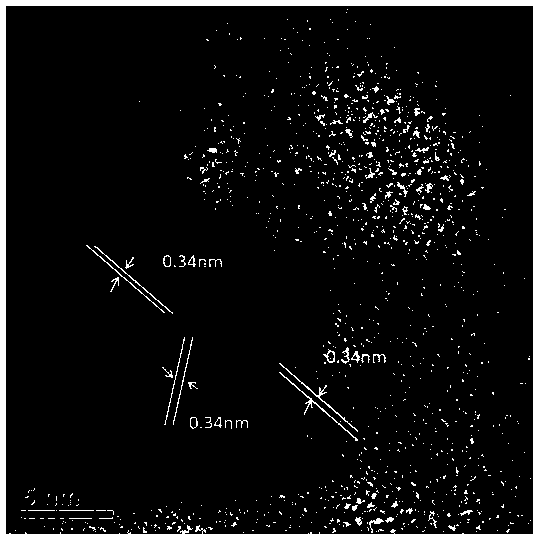

[0031] The preparation method of described layered intercalation titanium dioxide composite material, the steps are as follows:

[0032] The first step is to pre-treat the oceanic manganese nodules. The massive manganese nodules are crushed, and the powdered manganese nodules obtained by grinding are easier to carry out the next reaction;

[0033] The second step is to extract layered minerals from the raw manganese nodules. A strong oxidant for preparing layered minerals is used to corrode and oxidize impurity minerals in manganese nodules under high-temperature calcination, and provide potassium ions to exchange sodium ions in manganese nodules; after persulfate reaction, oxides or A large number of hydroxides are dissolved to produce relatively pure layered minerals;

[0034] The third step is to prepare the layered mineral intercalated with the titania precursor. After modification by organic modifiers, the interlayer of layered minerals changes from hydrophilic to lipo...

Embodiment 1

[0038] 1) Soak the raw oceanic manganese nodules in simulated seawater for 7 days, then crush and grind them. Sonicate for 60 min to fully disperse, and centrifuge at 15,000 rpm for 30 min to collect the lower granular precipitate and dry at 150 °C for 48 h;

[0039] 2) Mix the treated manganese nodules with a certain amount of potassium permanganate at a mass ratio of 10:1, add a small amount of oleic acid to grind them evenly, and calcinate the mixture at 1500 °C for 12 h. Put the calcined product into an Erlenmeyer flask filled with 2 mol / L ammonium persulfate solution, and stir for 120 min. After the reaction, filter and wash, and keep the filter residue at 150 °C for 24 h to obtain layered minerals;

[0040] 3) After ultrasonically dispersing the layered minerals, add the layered minerals into cetyltrimethylammonium bromide with 2 times the ion exchange capacity, stir and react at a constant temperature in a water bath at 90 °C for 12 h, and continue to age in a water ba...

Embodiment 2

[0047] 1) Soak the raw oceanic manganese nodules in simulated seawater for 1 day, then crush and grind them. Sonicate for 1 min to fully disperse, and centrifuge at 500 rpm for 1 min to collect the lower granular precipitate and dry at 25°C for 2 h;

[0048] 2) Mix the treated manganese nodules with a certain amount of potassium nitrate at a mass ratio of 0.1:1, add a small amount of stearic acid to grind them to make them evenly mixed, and calcinate the mixture at 500 °C for 1 h. Put the calcined product into an Erlenmeyer flask filled with 0.1mol / L potassium persulfate solution, and stir for 10 min. After the reaction, filter and wash, and keep the filter residue at 60 °C for 0.5 h to obtain layered minerals.

[0049] 3) After ultrasonically dispersing the layered minerals, add the layered minerals into cetylpyridinium chloride with 0.5 times the ion exchange capacity, stir and react at a constant temperature in a water bath at 40 °C for 0.5 h, continue to age in a water ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com