Papermaking wastewater treatment agent

A technology for papermaking wastewater and treatment agent, which is applied in processing wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problems of complex treatment process, insignificant treatment effect, and low equipment dependence. , to achieve the effect of simple and easy use, low equipment dependence, and significant processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

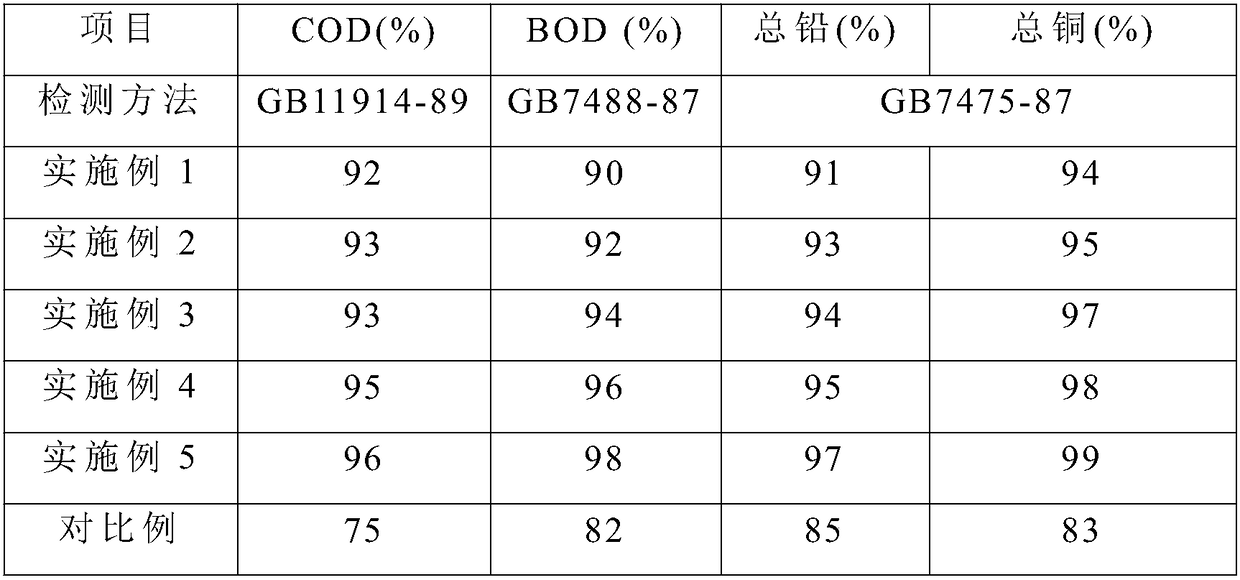

Examples

Embodiment 1

[0027] A papermaking wastewater treatment agent, made of the following components in parts by weight: 40 parts of triazine-based acrylamide ionic copolymer, 20 parts of methoxytrimethylsiloxy substituted sorbitol ester, polyaluminum chloride 10 parts of iron, 10 parts of carboxymethylbeta cyclodextrin sodium salt.

[0028] The triazine-based acrylamide ion copolymer is composed of 1,3,5-triacryloyl-1,3,5-triazine, acryloyloxyethyltrimethylammonium chloride, N-trimethylol Methacrylamide is prepared by solution polymerization and ion exchange reaction with sodium lignosulfonate;

[0029] The methoxytrimethylsiloxy substituted sorbitan ester is mono-9-octadecenoic acid-D-sorbitol ester and 1-methoxy-3-(trimethylsilyloxy)- 1,3-Butadiene can be produced by Diels-Alder reaction.

[0030] The preparation method of described triazine-based acrylamide ionic copolymer comprises the steps of:

[0031] 1) 5g of 1,3,5-triacryloyl-1,3,5-triazine, 10g of acryloyloxyethyltrimethylammonium ...

Embodiment 2

[0036] A papermaking wastewater treatment agent, made of the following components in parts by weight: 43 parts of triazine-based acrylamide ionic copolymer, 23 parts of methoxytrimethylsiloxy substituted sorbitol ester, polyaluminum chloride 12 parts of iron, 11 parts of carboxymethylbeta cyclodextrin sodium salt.

[0037] The triazine-based acrylamide ion copolymer is composed of 1,3,5-triacryloyl-1,3,5-triazine, acryloyloxyethyltrimethylammonium chloride, N-trimethylol Methacrylamide is prepared by solution polymerization and ion exchange reaction with sodium lignosulfonate;

[0038] The methoxytrimethylsiloxy substituted sorbitan ester is mono-9-octadecenoic acid-D-sorbitol ester and 1-methoxy-3-(trimethylsilyloxy)- 1,3-Butadiene can be produced by Diels-Alder reaction.

[0039] The preparation method of described triazine-based acrylamide ionic copolymer comprises the steps of:

[0040] 1) 5g of 1,3,5-triacryloyl-1,3,5-triazine, 10g of acryloyloxyethyltrimethylammonium ...

Embodiment 3

[0045] A papermaking wastewater treatment agent, made of the following components in parts by weight: 45 parts of triazine-based acrylamide ionic copolymer, 25 parts of methoxytrimethylsiloxy substituted sorbitol ester, polyaluminum chloride Iron 13 parts, carboxymethyl beta cyclodextrin sodium salt 13 parts.

[0046] The triazine-based acrylamide ion copolymer is composed of 1,3,5-triacryloyl-1,3,5-triazine, acryloyloxyethyltrimethylammonium chloride, N-trimethylol Methacrylamide is prepared by solution polymerization and ion exchange reaction with sodium lignosulfonate.

[0047] The methoxytrimethylsiloxy substituted sorbitan ester is mono-9-octadecenoic acid-D-sorbitol ester and 1-methoxy-3-(trimethylsilyloxy)- 1,3-Butadiene can be produced by Diels-Alder reaction.

[0048] The preparation method of described triazine-based acrylamide ionic copolymer comprises the steps of:

[0049] 1) 5g of 1,3,5-triacryloyl-1,3,5-triazine, 10g of acryloyloxyethyltrimethylammonium chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com