Foam concrete adopting artificial compound lightweight aggregate and preparation method thereof

A foamed concrete and lightweight aggregate technology, applied in the field of lightweight aggregate foamed concrete, can solve the problems of mass fluctuation promotion and application, unstable apparent density and mechanical properties of ceramsite foamed concrete, etc. The effect of small, single strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

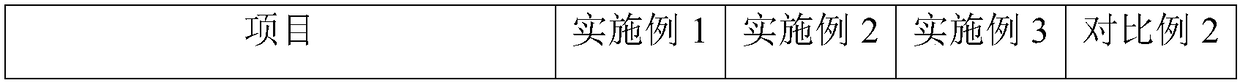

Embodiment 1

[0046] The foamed concrete using artificial composite lightweight aggregate in this example is prepared from water and the following raw materials: 315kg of cement, 135kg of fly ash, 17.5kg of quicklime, 4.0kg of gypsum, 1.7kg of water reducing agent, and 1.1kg of foaming agent , artificial composite lightweight aggregate 860L; water-binder ratio is 0.36.

[0047] Wherein, the artificial composite lightweight aggregate used is prepared by the following method:

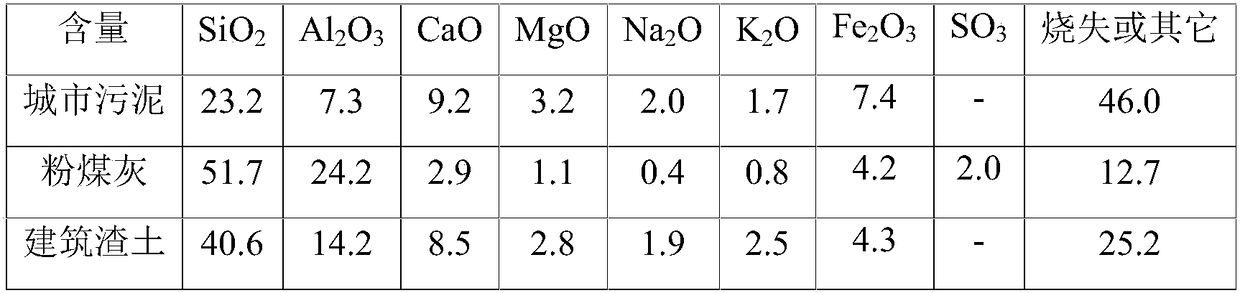

[0048] 1) The municipal sludge, fly ash and construction dregs are respectively crushed, ground and passed through a 150-mesh sieve to make powder. The mass ratio of municipal sludge, fly ash and construction dregs is 45:45:10 Mix the powders at the same ratio, add calcium carbonate powder and straw powder, and mix uniformly to obtain a raw powder mixture; wherein, the total mass of calcium carbonate powder and straw powder is 10% of the mass of the raw powder mixture; The mass ratio is 1:0.4;

[0049] 2) Add water w...

Embodiment 2

[0056] The foamed concrete using artificial composite lightweight aggregate in this example is prepared from water and the following raw materials: 320kg of cement, 130kg of fly ash, 16.0kg of quicklime, 4.5kg of gypsum, 1.8kg of water reducing agent, and 1.0kg of foaming agent , artificial composite lightweight aggregate 880L; water-binder ratio is 0.37.

[0057] Wherein, the artificial composite lightweight aggregate used is prepared by the following method:

[0058] 1) The municipal sludge, fly ash and construction dregs are crushed and ground respectively and passed through a 150-mesh sieve to make powder. The mass ratio of municipal sludge, fly ash and construction dregs is 50:40:10 Mix the powders at the same ratio, add calcium carbonate powder and straw powder, and mix uniformly to obtain a raw powder mixture; wherein, the total mass of calcium carbonate powder and straw powder is 10% of the mass of the raw powder mixture; The mass ratio is 1:0.45;

[0059] 2) In the ...

Embodiment 3

[0066] The foamed concrete using artificial composite lightweight aggregate in this example is prepared from water and the following raw materials: 330kg of cement, 120kg of fly ash, 17.0kg of quicklime, 4.2kg of gypsum, 2.0kg of water reducing agent, and 1.2kg of foaming agent , artificial composite lightweight aggregate 900L; water-binder ratio is 0.38.

[0067] Wherein, the artificial composite lightweight aggregate used is prepared by the following method:

[0068] 1) The municipal sludge, fly ash and construction dregs are respectively crushed, ground and passed through a 150-mesh sieve to make powder. The mass ratio of municipal sludge, fly ash and construction dregs is 45:40:15 Mix the powders at the same ratio, add calcium carbonate powder and straw powder, and mix uniformly to obtain a raw powder mixture; wherein, the total mass of calcium carbonate powder and straw powder is 10% of the mass of the raw powder mixture; The mass ratio is 1:0.5;

[0069] 2) Add water w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com