Wormlike micelle constructed by electrostatic based tetrameric surfactant

A surfactant and electrostatic technology, applied in the direction of cationic surface active compounds, drilling compositions, amino compound preparation, etc., to achieve the effect of simple purification process, high biodegradability, and avoid synthesis reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: tetramer quaternary ammonium salt surfactant synthetic route

[0034] Electrostatically constructed tetrameric surfactant, the structural formula is as follows:

[0035]

[0036] The synthetic route of the tetrameric surfactant of electrostatic construction is as follows:

[0037]

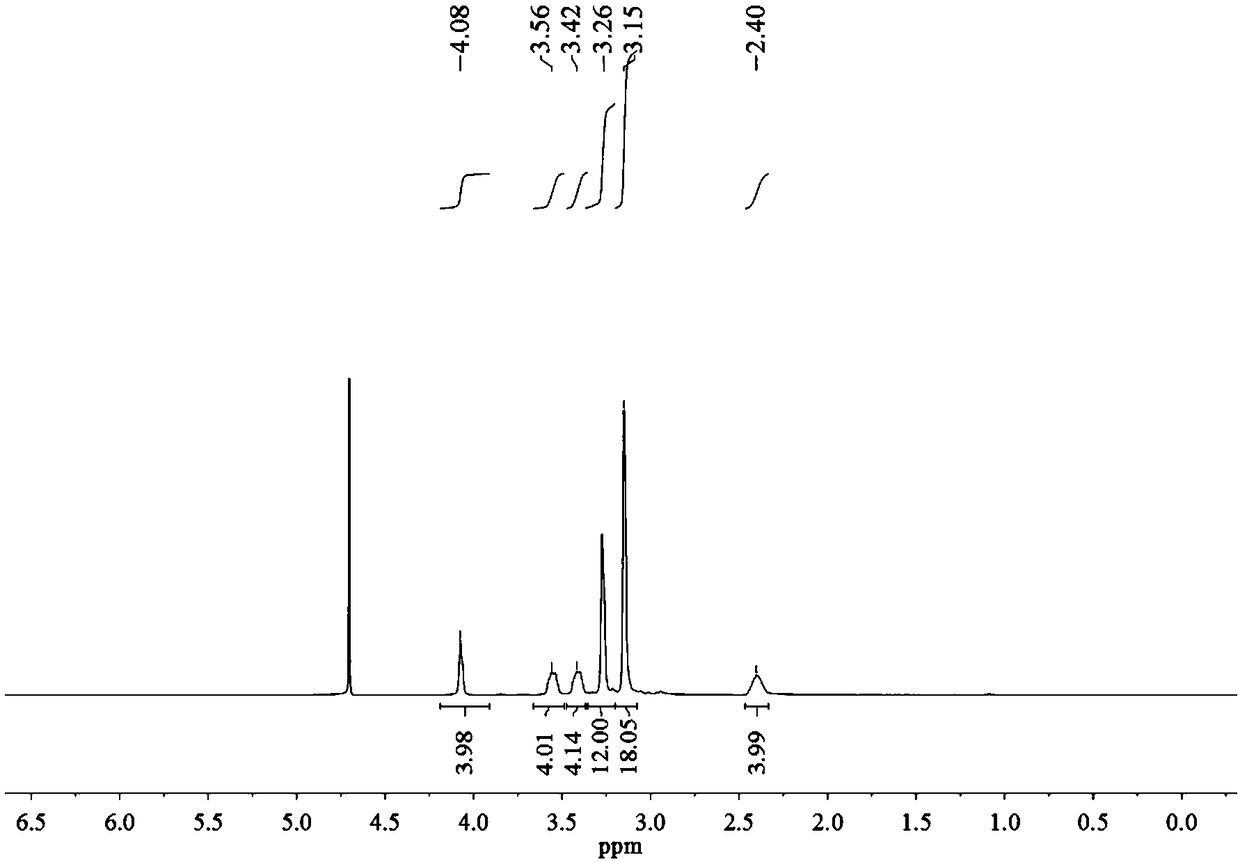

[0038] The preparation method of electrostatically constructed tetrameric surfactant is to mix trimethylamine and 1,3-dibromopropane at a molar ratio of 1:5 to generate 3-bromo-N,N,N-trimethylpropane-1 - Ammonium. 3-Bromo-N,N,N-trimethylpropan-1-ammonium and N 1 ,N 1 ,N 2 ,N 2 -Tetramethylethane-1,2-diamine is mixed according to the molar ratio of 2:1 to generate N 1 ,N 1 '-(ethane-1,2-diyl)bis(N 1 , N 1 ,N 3 ,N 3 ,N 3 - pentamethylpropane-1,3-diammonium). N 1 ,N 1 '-(ethane-1,2-diyl)bis(N 1 , N 1 ,N 3 ,N 3 ,N 3 -pentamethylpropane-1,3-diammonium) mixed with sodium oleate in an equimolar ratio to generate the final electrostatically constructed tetrameri...

Embodiment 2

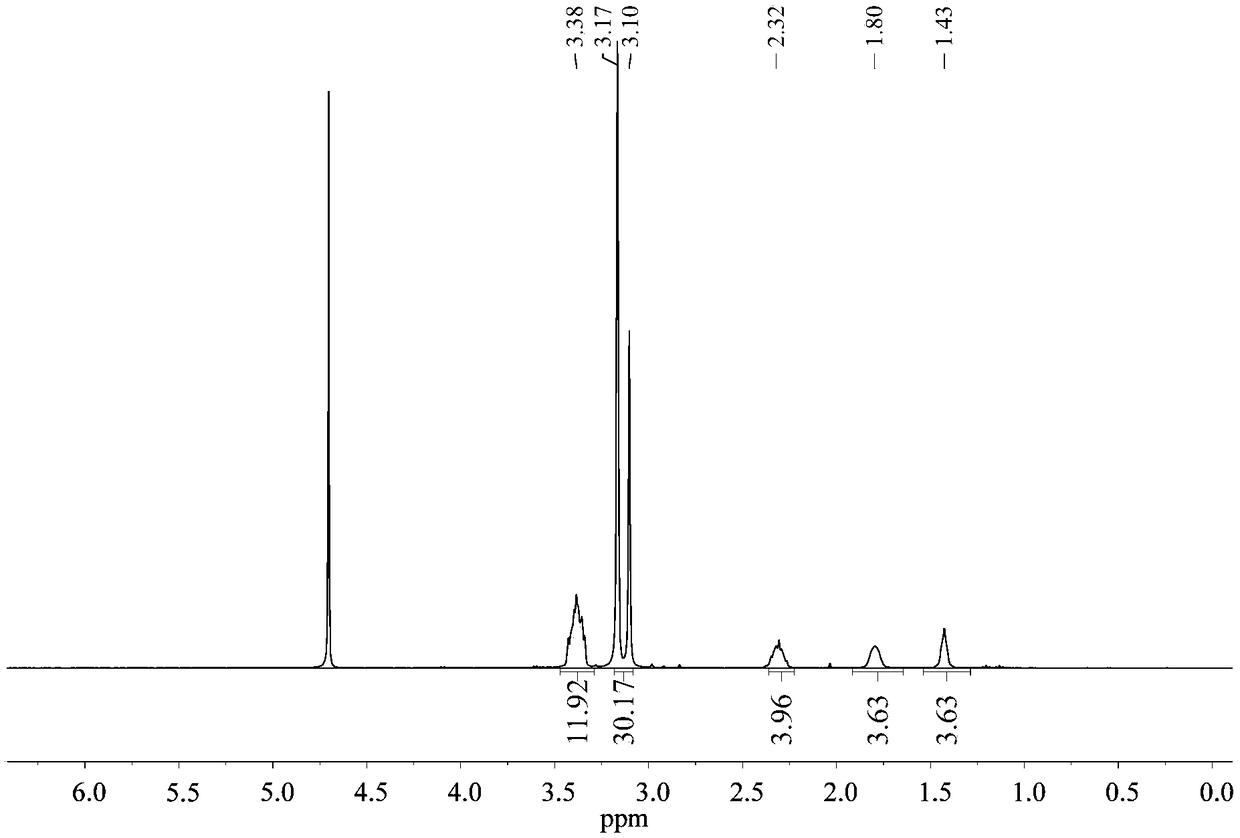

[0039] Example 2: Synthesis of 3-bromo-N,N,N-trimethylpropan-1-ammonium

[0040] Add 1,3-dibromopropane (101g 0.5mol), trimethylamine (5.9g 0.1mol) and acetone (300g) into a 500ml single-necked bottle, and react at 10°C for 4 hours. After the reaction, remove the acetone by suction filtration . Then wash the white filter cake with acetone, and finally recrystallize the white solid three times with ethanol to obtain the final pure product 3-bromo-N,N,N-trimethylpropan-1-ammonium. The yield is 71%, and the yield=(mole amount of raw material / mole amount of product)×100%.

Embodiment 3

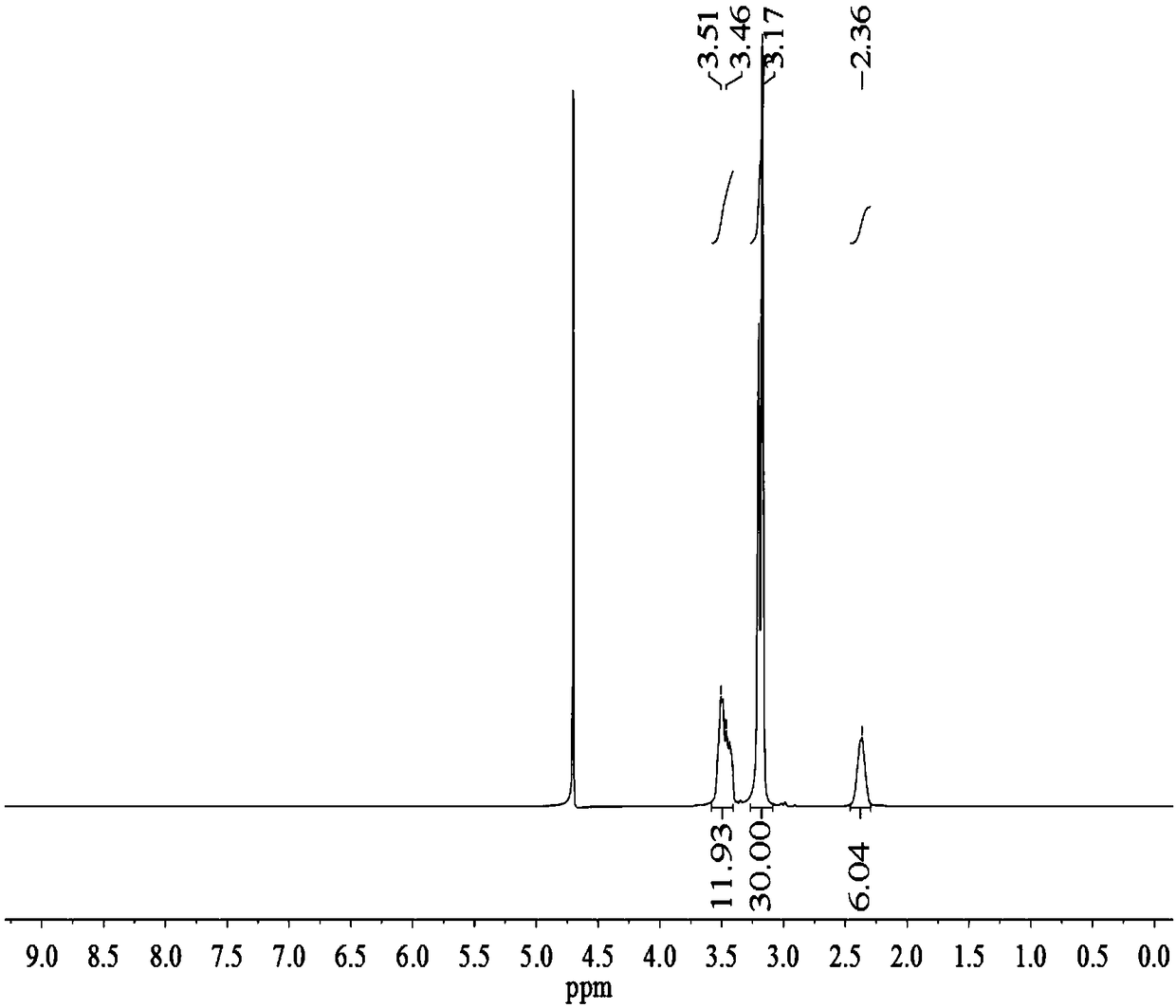

[0041] Example 3: Synthesis of N1, N1'-(ethane-1,2-diyl)bis(N1,N1,N3,N3,N3-pentamethylpropane-1,3-diammonium)

[0042] 3-bromo-N,N,N-trimethylpropan-1-ammonium (36.2g, 0.2mol), N 1 ,N 1 ,N 2 ,N 2 -Tetramethylethane-1,2-diamine (11.6g, 0.1mol) and ethanol (200g) were put into a 500ml single-necked bottle, and stirred at 70°C for 10 hours after the addition was completed. After fully reacting, the solvent was removed by rotary evaporation to obtain N1,N1'-(ethane-1,2-diyl)bis(N1,N1,N3,N3,N3-pentamethylpropane-1,3-diammonium ). Yield 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com