Rubber magnetic stripe and preparation method thereof

A rubber magnetic strip and rubber technology, applied in the field of rubber magnetic strip and its preparation, can solve the problems affecting the quality and service life of finished products, uneven vulcanization degree inside and outside, unsatisfactory heat treatment effect, etc., achieve uniform vulcanization inside and outside, ensure speed and Great effect of utilization rate and magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of above-mentioned rubber magnetic strip, comprises the following steps:

[0052] 1) Disperse permanent ferrite magnetic powder in water to form a suspension, then add alcohol and transfer to a sealed mixing tank, stir for 20-40 minutes, then add coupling agent, stir for 7-9 hours, remove water, and obtain modified magnetic powder;

[0053] 2) Add modified magnetic powder, rubber, plasticizer, accelerator, activator, anti-aging agent and vulcanizing agent into the internal mixer, knead for 5-8 minutes, then transfer the materials to the open mixer, and knead for 2-3 minutes. get the billet;

[0054] 3) Leave the blank for 4 to 8 hours, then knead, crush, and calender the tablet to obtain a semi-finished tablet;

[0055] 4) cutting the semi-finished sheet into a suitable size, putting it into a vulcanization tank, and vulcanizing it to obtain a vulcanized sheet;

[0056] 5) Put the vulcanized sheet into a microwave chamber, microwave for 30-50 se...

Embodiment 1

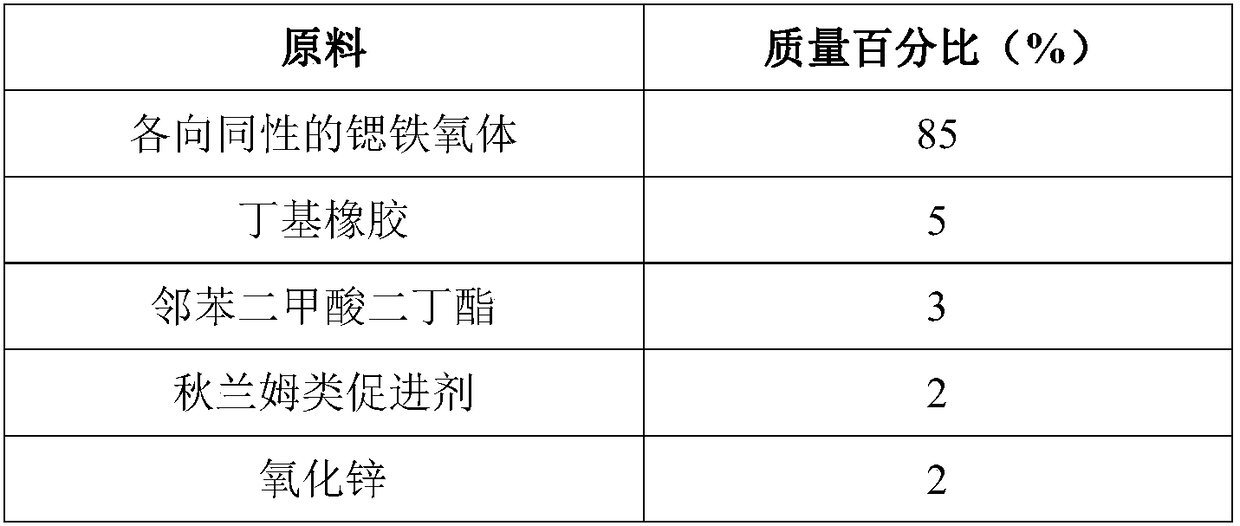

[0059] A rubber magnetic strip, its raw material composition is shown in the following table:

[0060] Table 1 The raw material composition table of a kind of rubber magnetic strip

[0061] raw material

Mass percentage (%)

Anisotropic strontium ferrite

80

Nitrile rubber

10

Dioctyl phthalate

4

Thiuram Accelerators

3

1

Antiager D

0.5

1

0.5

[0062] The preparation method of above-mentioned rubber magnetic strip is as follows:

[0063] 1) Disperse permanent ferrite magnetic powder in water to form a suspension, then add alcohol and transfer to a sealed mixing tank, stir for 30 minutes, then add coupling agent, stir for 8 hours, remove water, and obtain modified magnetic powder;

[0064] 2) Add the modified magnetic powder, rubber, plasticizer, accelerator, activator, anti-aging agent and vulcanizing agent into the internal mixer, knead for 7...

Embodiment 2

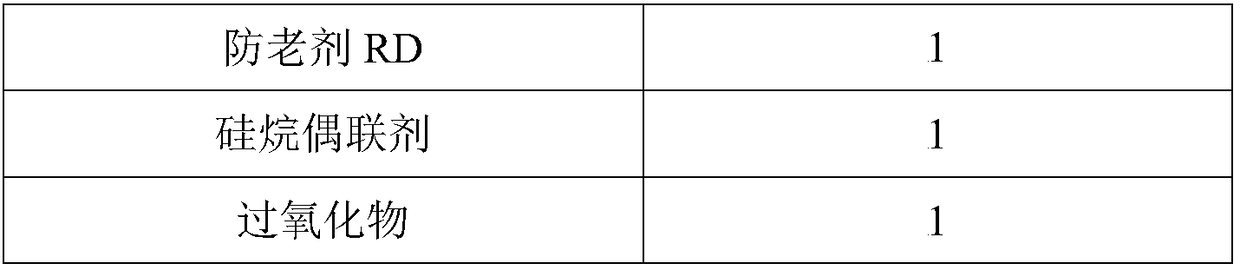

[0069] A rubber magnetic strip, its raw material composition is shown in the following table:

[0070] Table 2 The raw material composition table of a kind of rubber magnetic strip

[0071]

[0072]

[0073]The preparation method of above-mentioned rubber magnetic strip is as follows:

[0074] 1) Disperse permanent ferrite magnetic powder in water to form a suspension, then add alcohol and transfer to a sealed mixing tank, stir for 30 minutes, then add coupling agent, stir for 8 hours, remove water, and obtain modified magnetic powder;

[0075] 2) Add modified magnetic powder, rubber, plasticizer, accelerator, activator, anti-aging agent and vulcanizing agent into the internal mixer, knead for 6 minutes, then transfer the material to the open mixer, and knead for 2 minutes to obtain a billet;

[0076] 3) Leave the blank for 5 hours, then knead, crush, and calender the tablet to obtain a semi-finished tablet;

[0077] 4) cutting the semi-finished sheet into a suitable s...

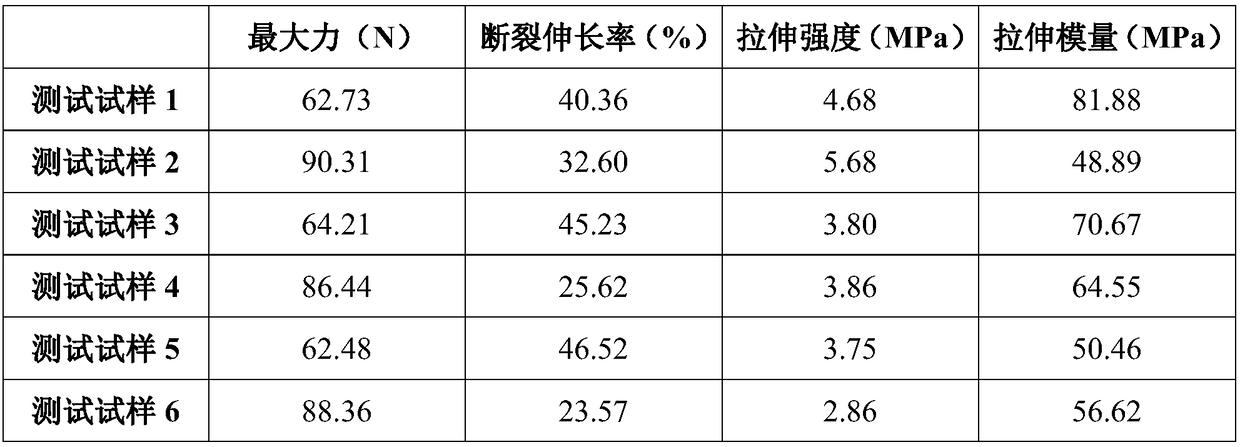

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com