A method for adding color and aroma to distilled rice wine

A technology of rice wine and red yeast pigment, which is applied in the field of adding color and aroma to distilled rice wine, which can solve the problems of long fermentation time for aroma production, limited nutrition of distilled rice wine, and the need to strengthen health care functions, so as to shorten the aroma production time and be easy to operate , the effect of increasing the content of ester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

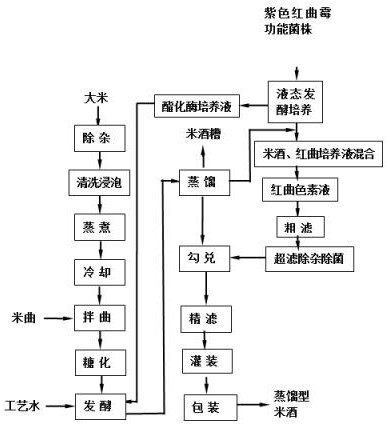

[0026] Embodiment 1: a kind of method to distilled type rice wine color-enhancing and flavor-enhancing, method is as follows:

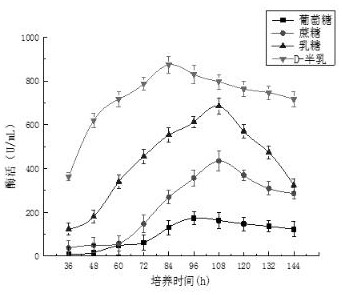

[0027] 1) The Monascus purple strain was mixed with D-galactose 0.4%, beef extract 1%, vitamin B2 0.1%, L-glutamic acid 0.1%, anhydrous CaCl 2 0.1%, MgSO 4 ·7H 2 In a culture medium composed of 0.1% O and the rest of water, at an initial pH of 4.3, a culture temperature of 25°C, a shaker speed of 140r / min, a liquid volume of 40 mL / 250 mL, and an inoculation volume of 8% (v / v) Cultivate for 72 hours to obtain a culture of high-yielding esterase;

[0028] 2) The Monascus purple strain was mixed with 4% glucose, 2% peptone, 0.08% FeSO 4 , 0.1% L-Glu and the rest of water, fermented at 28°C for 3 days; then mixed the culture with distilled rice wine (previously prepared distilled rice wine) at a mass ratio of 1:0.5 , and stirred and extracted, centrifuged at 6000 r / min for 10 minutes, and the supernatant was sterilized by ultrafiltration and macromol...

Embodiment 2

[0031] Embodiment 2: a kind of method to distilled type rice wine color-enhancing and flavor-enhancing, method is as follows:

[0032] 1) The Monascus purple strain was mixed with D-galactose 0.7%, beef extract 2%, vitamin B2 0.2%, L-glutamic acid 0.3%, anhydrous CaCl 2 0.2%, MgSO 4 ·7H 2 In a culture medium composed of 0.15% O and the rest of water, at an initial pH of 4.5, a culture temperature of 30°C, a shaker speed of 150r / min, a liquid volume of 45 mL / 250 mL, and an inoculation volume of 9% (v / v) Cultivate for 85h to prepare esterifying enzyme culture solution;

[0033] 2) The Monascus purple strain was mixed with 6% glucose, 2.3% peptone, 0.09% FeSO 4 , 0.2% L-Glu and the rest of water, fermented at 30 °C for 3.5 days; then mixed the culture with distilled rice wine (previously prepared distilled rice wine) in a mass ratio of 1:0.8 , and stirred and extracted, centrifuged at 7000 r / min for 13 min, and the supernatant was sterilized by ultrafiltration and macromolecul...

Embodiment 3

[0036] Embodiment 3: a kind of method to distilled type rice wine color-enhancing and flavor-enhancing, method is as follows:

[0037] 1) The Monascus purple strain was mixed with D-galactose 1%, beef extract 3%, vitamin B2 0.3%, L-glutamic acid 0.5%, anhydrous CaCl 2 0.3%, MgSO 4 ·7H 2 In a culture medium composed of O 0.2% and the rest of water, at an initial pH of 4.7, a culture temperature of 35°C, a shaker speed of 160r / min, a liquid volume of 50 mL / 250 mL, and an inoculation volume of 10% (v / v) Cultivate for 96h to prepare esterifying enzyme culture solution;

[0038] 2) The Monascus purple strain was mixed with 8% glucose, 2.5% peptone, 0.10% FeSO 4 , 0.3% L-Glu and the rest of water, fermented at 32 °C for 4 days; then mixed the culture with distilled rice wine (previously prepared distilled rice wine) at a mass ratio of 1:1 , and stirred and extracted, centrifuged at 8000 r / min for 15 min, and the supernatant was sterilized by ultrafiltration and macromolecular su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com