A preparation method of laser-assisted electric jet deposition soft-hard composite coating tool

A soft-hard composite, laser-assisted technology, applied in coating, superimposed layer plating, metal material coating process, etc., can solve the problems of expensive powder, affecting tool life, high cost, reducing cutting temperature, reducing Cutting force, effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The tool material used in this embodiment is W18Cr4V high-speed steel, and the material of the soft coating powder is MoS 2 , the material of the hard coating powder is Al 2 o 3 , the solvent is deionized water, the binder is polyvinyl alcohol, and the material of the soft coating layer powder is MoS 2 .

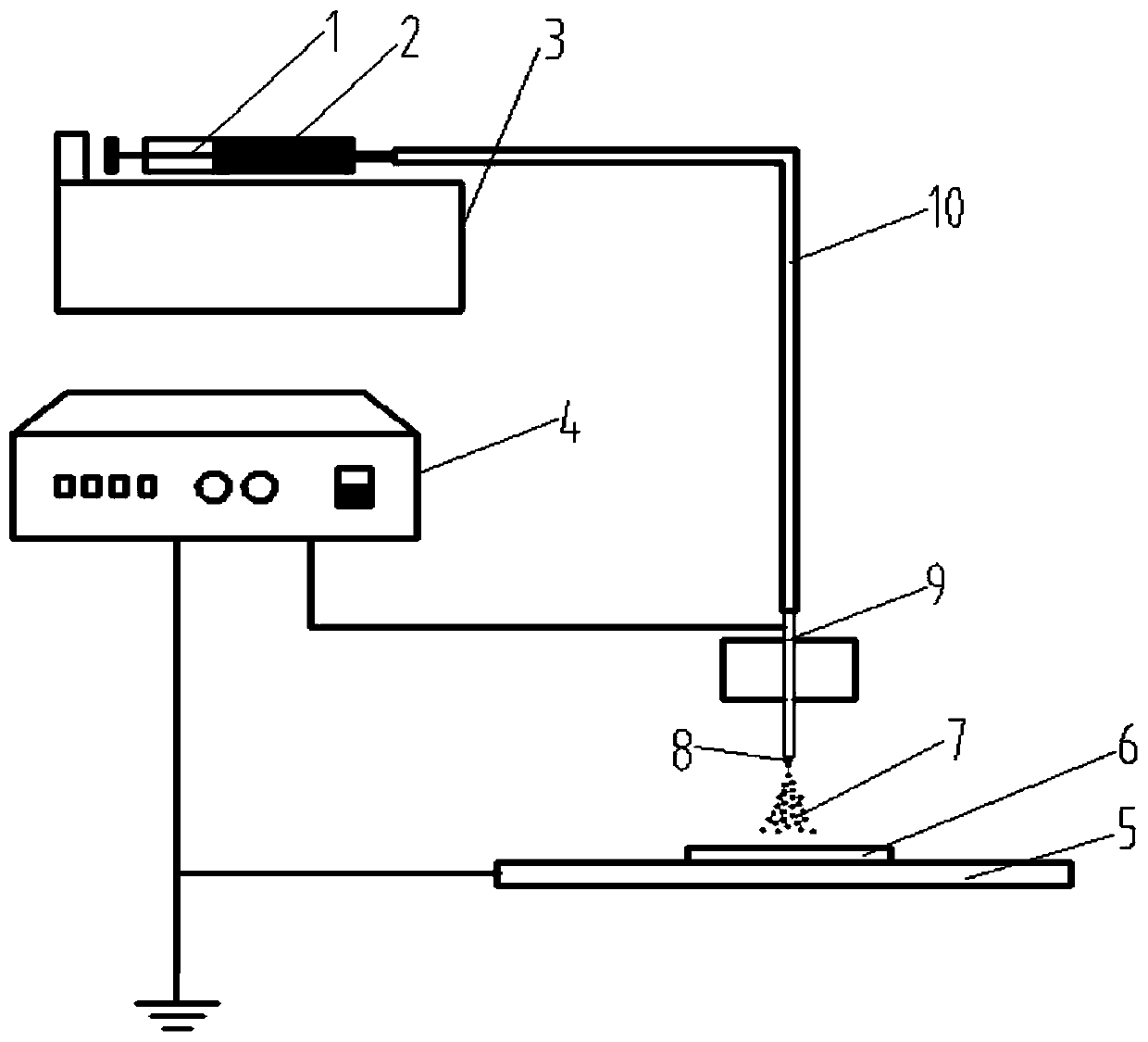

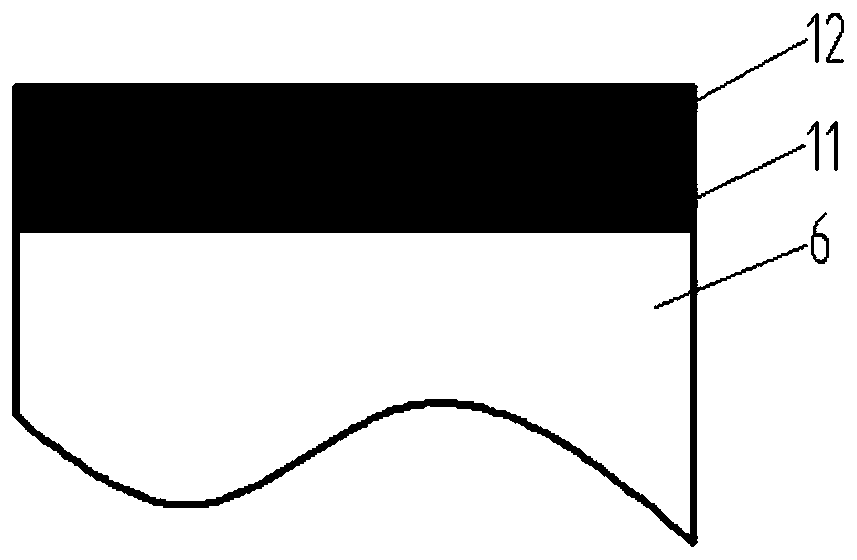

[0050] like Figure 1-2 Shown, a kind of preparation method of laser-assisted electric jet deposition soft-hard composite coating tool, comprises the following steps:

[0051] (1) Ultrasonic cleaning of the tool in acetone and absolute ethanol for 20 minutes in order to remove the dirt on the surface;

[0052] (2) Mix the hard coat powder, solvent, and binder with a weight ratio of 12:40:1 to prepare a suspension (hereinafter referred to as hard coat slurry), and put the hard coat slurry 2 into Syringe 1, control the hard coat slurry by micro-injection pump 3 to 4 x 10 -13 m 3 / s flow rate, and form micron-scale stable jets 8 and nano-droplets 7 in the high-vol...

Embodiment 2

[0060] The tool material used in this embodiment is W6Mo5Cr4V2 high-speed steel, and the material of the soft coating powder is WS 2 , the hard coating powder is made of cemented carbide, and its important components are 80% WC, 10% Co, 5% W, 1.5% VC, 1% Cr 3 C 2 , 1% Ni, 1% Al and 0.5% Mo, the solvent is ethanol, the binder is ethyl cellulose, and the material of the soft coating layer powder is WS 2 .

[0061] like Figure 1-2 Shown, a kind of preparation method of laser-assisted electric jet deposition soft-hard composite coating tool, comprises the following steps:

[0062] (1) Ultrasonic cleaning of the tool in acetone and absolute ethanol for 20 minutes in order to remove the dirt on the surface;

[0063] (2) Mix the hard coat powder, solvent, and binder with a weight ratio of 10:40:1 to obtain a suspension (hereinafter referred to as hard coat slurry), and put the hard coat slurry 2 into Syringe 1, control the hard coat slurry by micro-injection pump 3 to 4 x 10 -...

Embodiment 3

[0071] A kind of preparation method of laser-assisted electric jet deposition soft and hard composite coating tool, with embodiment 1, difference is: in step (2), the weight ratio of described hard coating powder, solvent, binding agent is 30: 30:5, the flow rate of the hard coat slurry is 5×10 -13 m 3 / s; the distance between the nozzle and the cutter substrate is 5mm; the moving speed of the nozzle is 40mm / s, the deposition thickness of the hard coating wet film is 100μm; the voltage of the high voltage electric field is 0.1Kv. In step (4), the laser parameters are: power 100W, spot diameter 2mm, scanning speed 4mm / s, overlapping rate 50%. In step (5), the wet film thickness of the soft coating is 80 μm, and the weight ratio of the soft coating powder, inorganic solvent, and binder is 10:15:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com