A kind of metal coating and its preparation method and application

A technology of metal plating and gold layer, applied in metal material coating process, metal pattern material, coating, etc., can solve the problems of difficult application of gold layer, interdiffusion of palladium layer, low density of nickel layer, etc., and achieve the preparation method Simple and easy to solve the effect of mutual diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

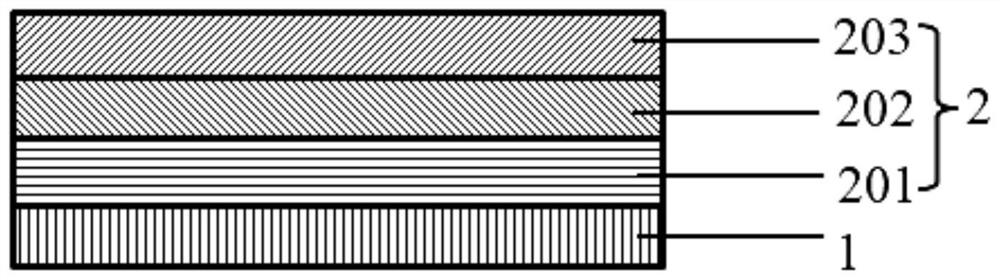

[0034] A metal coating such as figure 1 As shown, the metal plating layer (2) is located on the substrate (1), and there are palladium layer (201), nickel layer (202) and gold layer (203) in sequence from bottom to top.

[0035] The preparation method is as follows:

[0036] (1) Degreasing: Soak in acidic degreasing solution at 35-45°C for 2-3 minutes, then wash with water;

[0037] (2) Microetching: Soak in a mixed solution of sodium persulfate (60g / L) and sulfuric acid (20mL / L) for 1-2min at room temperature, then wash with water;

[0038] (3) Activation: use activator (10ppm Pd 2+ (complexed palladium salt), 5ppm surfactant, 30ppm complexing agent, sulfuric acid to adjust the pH to 1-1.5), activate at room temperature for 1-2min, and then wash with water;

[0039] (4) Electroless palladium: use electroless palladium plating solution (about 0.1g / L palladium salt, with 0.5-1g / L nitrogen-containing heterocyclic organic complexing agent, using sodium hypophosphite as reducin...

Embodiment 2

[0043] A metal coating, which is located on the substrate, from bottom to top is palladium layer, nickel layer and gold layer.

[0044] The difference between the preparation method and Example 1 is that in the present embodiment, the method of step (4) palladium plating layer is different, and in the present embodiment, the plating method of the palladium layer is electroplating palladium: utilize palladium electroplating solution (network Palladium salt 15g / L; NH 4 SO 4 80g / L; (NH 4 ) 2 HPO 4 60g / L; sulfamic acid 1g / L; urea 10g / L) at 45-55°C.

Embodiment 3

[0046] A metal coating, which is located on the substrate, from bottom to top is palladium layer, nickel layer and gold layer.

[0047]The difference between the preparation method and Example 1 is only that, in the present embodiment, the method of step (5) nickel plating layer is different, and in the present embodiment, the plating method of the nickel layer is electroplating: adopt nickel electroplating solution (nickel sulfate 280g / L; Nickel Chloride 40g / L; Boric Acid 45g / L; Cylinder 9mL / L; Brightener 0.2mL / L; pH 4.2) Plating at 50-60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com