Method for preparing Fe-N-C carbonaceous oxygen reduction catalyst through solvothermal method

A solvothermal and catalyst technology, applied in nanotechnology, structural parts, electrical components, etc. for materials and surface science, can solve the problems of low reserves, high overpotential, easy to fall off and dissolve, etc., to reduce production costs, Simplified synthesis steps and good doping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

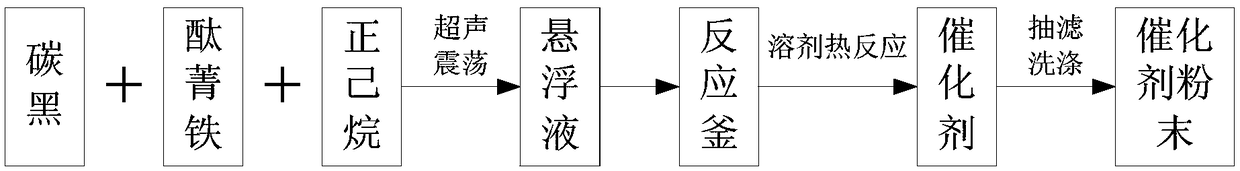

[0025] Embodiment 1: A method for preparing Fe-N-C carbonaceous oxygen reduction catalyst and catalyst slurry by solvothermal method, comprising the steps of:

[0026] Take 500 mg of commercial carbon black (VC72) powder, mix it with 210 mg of iron phthalocyanine, add 70 mL of n-hexane to form a suspension, and use analytically pure n-hexane for the n-hexane solution, and its mass percentage is greater than or equal to 97%; ultrasonically shake the suspension For 20 minutes, the carbon black powder is uniformly dispersed and iron phthalocyanine is fully dissolved, and then it is added to a high-temperature reactor for solvothermal reaction. Cool naturally to obtain catalyst;

[0027] The catalyst is suction-filtered and washed with a sufficient amount of absolute ethanol to remove the remaining unreacted iron phthalocyanine, and then dried to obtain catalyst powder.

[0028] 10 mg of prepared catalyst powder was mixed with 630 uL of absolute ethanol, 1270 uL of deionized wate...

Embodiment 2

[0029] Embodiment 2: a kind of method for preparing Fe-N-C type carbonaceous oxygen reduction catalyst by solvothermal method, comprises the steps:

[0030] Take 500 mg of carbon nanotubes and develop them into powder, mix them with 180 mg of iron phthalocyanine, add 60 mL of n-hexane to form a suspension, and the n-hexane solution is analytically pure, and its mass percentage is greater than or equal to 97%; ultrasonically vibrate the suspension for 20 minutes to make The carbon nanotube powder is uniformly dispersed, iron phthalocyanine is fully dissolved, and then it is added into a high-temperature reactor for solvothermal reaction. The reaction temperature is 160°C-200°C, and it is maintained for 10h-14h. After the reaction is completed, wait for it to cool naturally. get a catalyst;

[0031] The catalyst is suction-filtered and washed with a sufficient amount of absolute ethanol to remove the remaining unreacted iron phthalocyanine, and then dried to obtain catalyst powd...

Embodiment 3

[0032] Embodiment 3: a kind of method for preparing Fe-N-C type carbonaceous oxygen reduction catalyst by solvothermal method comprises the following steps:

[0033] Take 500 mg of graphene powder, mix it with 250 mg of iron phthalocyanine, add 100 mL of n-hexane to form a suspension, and the n-hexane solution is analytically pure, and its mass percentage is greater than or equal to 97%; ultrasonically vibrate the suspension for 20 minutes to make the graphene powder Uniformly disperse and fully dissolve iron phthalocyanine, then put it into a high-temperature reactor for solvothermal reaction, the reaction temperature is 160°C-200°C, keep for 10h-14h, after the reaction is completed, let it cool naturally to obtain the catalyst;

[0034] The catalyst is suction-filtered and washed with a sufficient amount of absolute ethanol to remove the remaining unreacted iron phthalocyanine, and then dried to obtain catalyst powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com