Preparation and product of responsive chitosan microsphere/cellulose hydrogel drug-loaded composite film

A technology of cellulose hydrogel and chitosan microspheres, which is applied in the field of biomedicine to achieve the effects of prolonging the action time, avoiding damage, and mild experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

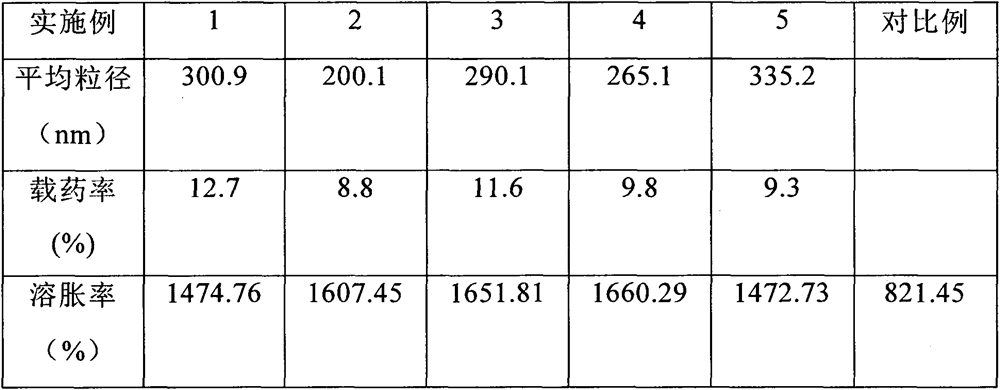

Embodiment 1

[0020] (1) Preparation of chitosan microspheres loaded with antibacterial drugs. Weigh 0.12g of chitosan, add it into 6mL of 1% acetic acid solution, stir until the chitosan is completely dissolved, then add 0.04g of tetracycline hydrochloride, stir until completely dissolved, add 1mL of Tween-80, ultrasonic 1min, as water Phase: Measure 24 mL of liquid paraffin, add 150 μL of 25% glutaraldehyde solution and 1 mL of Span-80, and sonicate for 2 min, as the oil phase. Drop the water phase into the oil phase, keep stirring for 30 minutes, then drop 50 μL of 25% glutaraldehyde solution, keep stirring at 40°C for 2 hours, then centrifuge, wash the precipitate with petroleum ether three times, and vacuum freeze-dry for 24 hours. Chitosan microspheres loaded with tetracycline hydrochloride were obtained.

[0021] (2) Preparation of drug-loaded composite film. Weigh 0.1 g of carboxymethyl cellulose and dissolve it in 10 mL of water to obtain a carboxymethyl cellulose solution with a...

Embodiment 2

[0023] (1) Weigh 0.24g of chitosan, add it to 12mL of 1% acetic acid solution, stir until the chitosan is completely dissolved, then add 0.08g of tetracycline hydrochloride, stir until completely dissolved, add 1mL of Tween-80, and sonicate for 1min , as the water phase; measure 48 mL of liquid paraffin, add 300 μL of 25% glutaraldehyde solution and 1 mL of Span-80, and sonicate for 1 min, as the oil phase. Drop the water phase into the oil phase, keep stirring for 35 minutes, then drop 100 μL of 25% glutaraldehyde solution, keep stirring at 40°C for 2 hours, then centrifuge, wash the precipitate with petroleum ether three times, and vacuum freeze-dry for 24 hours. Chitosan microspheres loaded with tetracycline hydrochloride were obtained.

[0024] (2) Preparation of drug-loaded composite film. Weigh 0.15 g of carboxymethyl cellulose and dissolve it in 10 mL of water to obtain a carboxymethyl cellulose solution with a concentration of 1.5%. Add 0.2 g of 1-(3-dimethylaminopro...

Embodiment 3

[0026] (1) Weigh 0.36g of chitosan, add it to 18mL of 1% acetic acid solution, stir until the chitosan is completely dissolved, then add 0.08g of tetracycline hydrochloride, stir until completely dissolved, add 2mL of Tween-80, and sonicate for 1min , as the water phase; measure 72 mL of liquid paraffin, add 450 μL of 25% glutaraldehyde solution and 1 mL of Span-80, and sonicate for 1.5 min, as the oil phase. Drop the water phase into the oil phase, keep stirring for 40 minutes, then drop 150 μL of 25% glutaraldehyde solution, keep stirring at 40°C for 2 hours, then centrifuge, wash the precipitate three times with petroleum ether, and vacuum freeze-dry for 24 hours. Chitosan microspheres loaded with tetracycline hydrochloride were obtained.

[0027] (2) Preparation of drug-loaded composite film. Weigh 0.2 g of carboxymethyl cellulose and dissolve it in 10 mL of water to obtain a 2% carboxymethyl cellulose solution. Add 0.3 g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com