Method for determining contents of aluminum, niobium, tungsten and chromium in high-niobium-aluminum-titanium alloy

An aluminum-titanium alloy and determination method technology, applied in the field of spectrochemical analysis and testing, can solve the problems of large differences, poor analysis efficiency, different analysis methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1: Prepare the sample solution to be tested first: weigh 0.1g of the high-niobium aluminum-titanium alloy sample to be tested in a polytetrafluoroethylene beaker, add distilled water and 15mL of hydrochloric acid, then add 2mL of hydrofluoric acid drop by drop, and heat at low temperature until The sample is completely dissolved, then add 2 mL of nitric acid, continue to heat at low temperature until the reddish-brown smoke in the solution disappears, cool to room temperature, transfer to a 250 mL plastic volumetric flask, add water to make up the volume, and shake well to obtain the sample solution to be tested, set aside, parallel Process 2 samples to be tested;

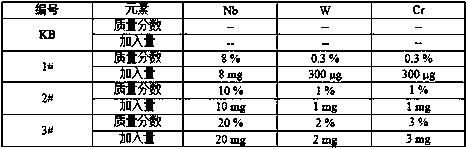

[0037] Step 2, preparation of standard solution: Weigh 4 parts of high-purity titanium and high-purity aluminum matched with the sample, and place them in 8 polytetrafluoroethylene beakers respectively. The purity of the high-purity titanium is 99.99%, and the high-purity The purity of pure aluminum is ...

Embodiment 2

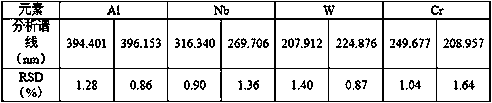

[0046] Embodiment 2: Determination of the detection limit of aluminum, niobium, tungsten, chromium content in high-niobium aluminum-titanium alloy

[0047] After the calibration curve is established, the measured value of the blank solution without adding the standard solution is the method blank value, and the parallel measurement is performed 10 times. Three times the standard deviation of the blank value is the detection limit of the method, and the results are listed in Table 3 below.

[0048] Table 3 Method detection limit

[0049]

[0050] It can be seen from Table 3 that the detection limits are low, all below 0.006%. It can be seen that this determination method has high sensitivity and can meet the needs of determination of aluminum, niobium, tungsten and chromium.

Embodiment 3

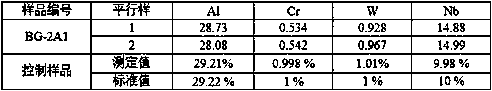

[0051] Embodiment 3: precision test

[0052] The BG-2A1 sample was measured 6 times, and the relative standard deviation RSD was the precision. The results are listed in Table 4 below:

[0053] Table 4 Precision test results

[0054]

[0055] It can be seen from the above table 4 that the relative standard deviation (RSD) of the repeated determination samples is not more than 5%, and the precision is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com