Graphene composite nano-copper conductive ink composition and preparation method thereof

A graphene composite and conductive ink technology, which is applied in ink, household utensils, applications, etc., can solve the problems of difficult dispersion of graphene fillers, high resistivity of conductive inks, easy aggregation of nanoparticles, etc., to achieve mass production and production High efficiency, solve the effect of easy reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

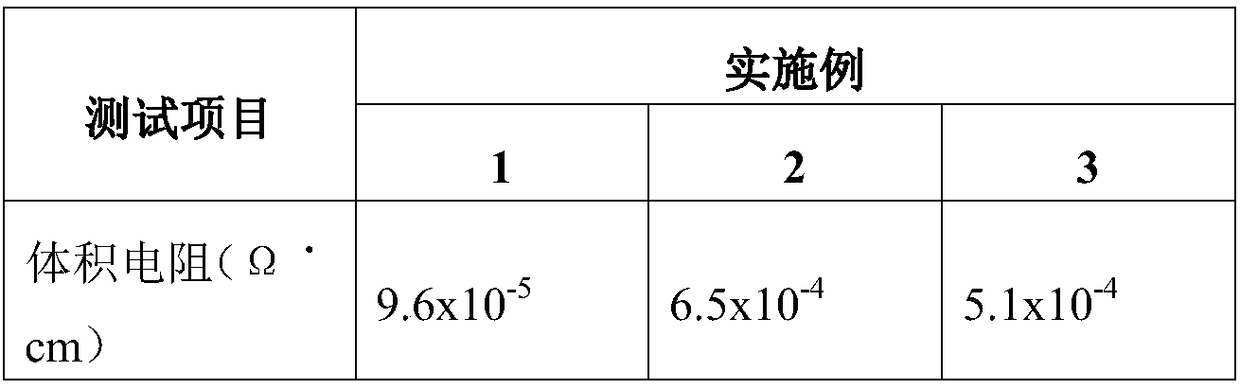

Embodiment 1

[0038] Preparation of graphene composite nano-copper conductive ink composition

[0039] Raw materials: 50wt% graphene-coated nano copper powder, 10wt% epoxy resin, 5wt% epoxy resin curing agent, 2.5wt% polyvinyl acetal, 20wt% organic solvent, 8wt% toughening agent, 1wt defoamer %, antioxidant 2wt%, adhesion promoter 1wt%, thixotropic agent 0.5wt%.

[0040] The particle size range of the metal copper of the above-mentioned graphene-coated nano-copper powder is 50-100 nanometers; the epoxy resin is bisphenol A epoxy resin; the epoxy resin curing agent is MOCA; polyvinyl acetal is polyvinyl acetal Formaldehyde; organic solvent is N,N-dimethylformamide and butanone; toughener is carboxy-terminated nitrile rubber; defoamer is polydimethylsiloxane, viscosity 500cPs; antioxidant is BHT; The bonding force promoter is a silane coupling agent with epoxy groups; the thixotropic agent is fumed silica.

[0041] Preparation steps:

[0042] (1) Preparation of graphene-coated nano-copper ...

Embodiment 2

[0052] Preparation of graphene composite nano-copper conductive ink composition

[0053] Raw materials: graphene coated nano-copper powder 64wt%, epoxy resin 8wt%, epoxy resin curing agent 4wt%, polyvinyl acetal 2wt%, organic solvent 15wt%, toughening agent 2wt%, defoamer 1.5wt %, antioxidant 1.5wt%, adhesion promoter 1wt%, thixotropic agent 1wt%.

[0054] The particle size range of the metal copper of the above-mentioned graphene-coated nano-copper powder is 50-100 nanometers; the epoxy resin is bisphenol F epoxy resin; the epoxy resin curing agent is DDS; polyvinyl acetal is polyvinyl acetal Butyraldehyde; organic solvent is N,N-dimethylacetamide and acetone; toughening agent is carboxyl-terminated nitrile rubber modified epoxy resin; defoamer is polydimethylsiloxane, viscosity 1500cPs; antioxidant The agent is 168 and 1010 mixed in a ratio of 1:1; the adhesion promoter is a silane coupling agent with amino groups; the thixotropic agent is hydrogenated castor oil.

[0055]...

Embodiment 3

[0066] Preparation of graphene composite nano-copper conductive ink composition

[0067] Raw materials: graphene coated nano-copper powder 68wt%, epoxy resin 9wt%, epoxy resin curing agent 5wt%, polyvinyl acetal 1wt%, organic solvent 11wt%, toughening agent 2wt%, defoamer 1wt% , Antioxidant 1wt%, adhesion promoter 1.5wt%, thixotropic agent 0.5wt%.

[0068] The particle size range of the metal copper of the above-mentioned graphene-coated nano-copper powder is 50-100 nanometers; the epoxy resin is bisphenol A epoxy resin; the epoxy resin curing agent is DDS; polyvinyl acetal is polyvinyl acetal Butyraldehyde; organic solvents are dipropylene glycol methyl ether and butanone; toughener is hydroxyl-terminated nitrile rubber; defoamer is polydimethylsiloxane, viscosity 1000cPs; antioxidant is BHT; adhesion promoter It is a silane coupling agent with an amino group; the thixotropic agent is hydrogenated castor oil.

[0069] Preparation steps:

[0070] (1) Preparation of graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com