A method for selective separation of phenolic compounds in coal direct conversion liquid oil

A phenolic compound and selective technology, applied in the field of coal chemical industry, can solve the problems of complex preparation process of extractant, serious pollution, harsh equipment, etc., and achieve the effect of avoiding phenol-containing wastewater, simple preparation process and less entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

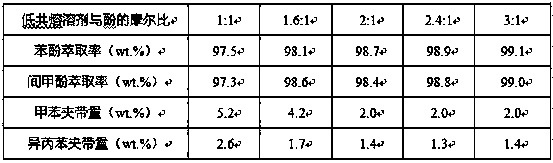

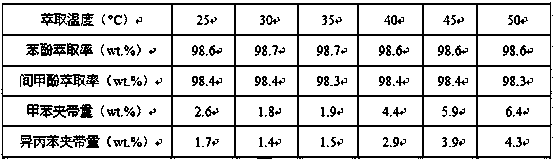

[0030] Weigh 6.7 g of choline chloride and 3.0 g of ethylene glycol (the molar ratio of choline chloride to ethylene glycol is 1:1) in a 50 ml Erlenmeyer flask with a cover, and stir at 70°C for 25 min to form a colorless Transparent liquid, namely deep eutectic solvent. Weigh 4.5 g of phenol, 8.1 g of toluene, and 2.4 g of n-hexane into a beaker to prepare a model oil with a phenol mass fraction of 30%.

[0031] The model oil was added to the prepared deep eutectic solvent (the molar ratio of deep eutectic solvent to phenol was 2:1), stirred at 35°C for 45 min, and allowed to stand to separate into layers. The upper oil phase was removed, weighed, and the mass concentrations of phenol and toluene in the upper oil phase were measured by GC. The extraction rate of phenol was calculated to be 99.2%, and the entrained amount of toluene was 6.7%.

Embodiment 2

[0033] Weigh 6.7 g of choline chloride and 6.4 g of malic acid (the molar ratio of choline chloride to malic acid is 1:1) in a 50 ml Erlenmeyer flask with a cover, and stir at 90 °C for 90 min to form a colorless liquid. That is, the deep eutectic solvent. Weigh 3.8 g phenol, 8.8 g toluene, and 2.4 g n-hexane into a beaker to prepare a model oil with a phenol mass fraction of 25%.

[0034] Add the model oil into the prepared deep eutectic solvent (the molar ratio of deep eutectic solvent to phenol is 2:1), stir at 35°C for 45 min, and let stand to separate layers. The upper oil phase was removed, weighed, and the mass concentrations of phenol and toluene in the upper oil phase were measured by GC, and the extraction rate of phenol was calculated to be 94.3%, and the entrained amount of toluene was 8.5%.

Embodiment 3

[0036] Weigh 6.7 g of choline chloride and 3.0 g of monoethanolamine (the molar ratio of choline chloride and monoethanolamine is 1:1) in a 50 ml Erlenmeyer flask with a cover, and stir at 75°C for 60 min to form a colorless liquid. That is, the deep eutectic solvent. Weigh 3.8 g phenol, 8.8 g toluene, and 2.4 g n-hexane into a beaker to prepare a model oil with a phenol mass fraction of 25%.

[0037] Add the model oil into the prepared deep eutectic solvent (the molar ratio of deep eutectic solvent to phenol is 2:1), stir at 35°C for 45 min, and let stand to separate layers. The upper oil phase was removed, weighed, and the mass concentrations of phenol and toluene in the upper oil phase were measured by GC, and the extraction rate of phenol was calculated to be 99.0%, and the entrained amount of toluene was 18.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com