Silicon-rich SiOx-C material and preparation method and application thereof

A silicon-rich and silicon source technology, applied in the field of silicon-rich SiOx-C materials and their preparation, can solve the problems of low first-efficiency of SiO materials, and achieve the effects of easy control, large-scale production, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

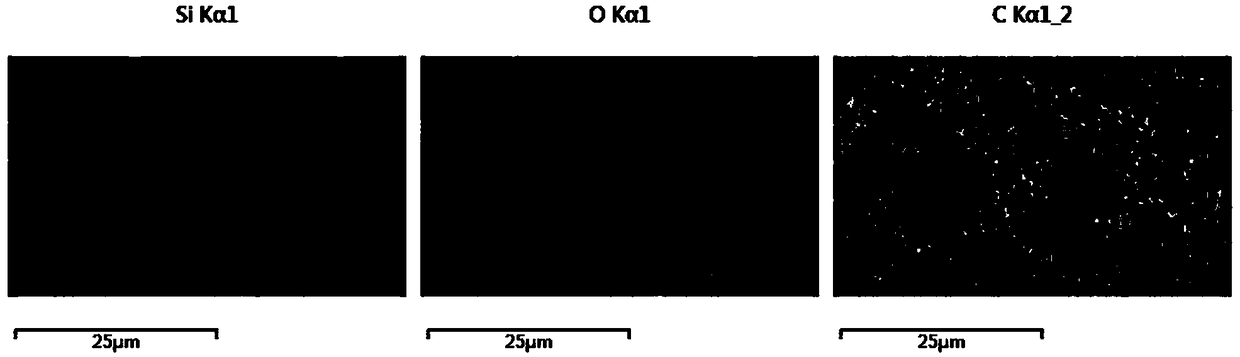

Image

Examples

Embodiment 1

[0032] Put 10g of SiO in a porcelain boat, then place it in a tube furnace in an argon protective atmosphere, raise the temperature of the tube furnace to 900 °C at a heating rate of 5 °C / min, keep it warm for 2 hours, and take out the prepared SiO after cooling down x . SiO x Mix with 40% HF aqueous solution at a mass ratio of 2:1, soak for 0.5h, then filter, wash with deionized water for 3 times until the washing liquid is neutral, and then place it in a vacuum-dried vacuum with a vacuum degree of -0.8MPa The porous silicon-based material was prepared by drying at 80°C in an oven. Take 5g of porous silicon-based material and place it in a CVD furnace, pass in argon gas to exhaust the air in the CVD furnace, then pass in silane gas, the gas flow rate is 4mL / min, and the temperature of the tube furnace is raised to 600°C, keep warm for 2 hours, stop feeding silane, then raise the temperature of the tube furnace to 800°C, feed acetylene gas, the gas flow rate is 4mL / min, keep...

Embodiment 2

[0034] Put 10g of SiO in a porcelain boat, then place it in a tube furnace in a nitrogen protective atmosphere, raise the temperature of the tube furnace to 900°C at a heating rate of 5°C / min, keep it warm for 12h, and take out the prepared SiO after cooling down x . SiO x Mix with 35% HF aqueous solution at a mass ratio of 1:2, soak for 2 hours, then filter, wash with deionized water for 3 times until the washing liquid is neutral, and then place it in a vacuum drying oven with a vacuum degree of -1MPa , and dried at 80°C to prepare a porous silicon-based material. Take 5 g of porous silicon-based materials and place them in a CVD furnace, blow in nitrogen gas to exhaust the air in the CVD furnace, and then pass in silane gas with a gas flow rate of 1 mL / min, and raise the temperature of the tube furnace to 600 °C at a heating rate of 5 °C / min. ℃, keep warm for 12h, stop feeding silane gas, raise the temperature of the tube furnace to 700°C, feed acetylene gas, the gas flow...

Embodiment 3

[0036] Put 10g of SiO in a porcelain boat, then place it in a tube furnace in a nitrogen protective atmosphere, raise the temperature of the tube furnace to 1200 °C at a heating rate of 5 °C / min, keep it for 2 hours, and take out the prepared SiO after cooling down x . SiO x Mix with HF aqueous solution with a mass fraction of 44% at a mass ratio of 2:1, soak for 0.5h, then filter, wash with deionized water for 3 times until the washing liquid is neutral, and then place it in a vacuum-dried vacuum with a vacuum degree of -0.8MPa The porous silicon-based material was prepared by drying at 100°C in an oven. Take 5 g of porous silicon-based materials and place them in a CVD furnace, blow in nitrogen gas to exhaust the air in the CVD furnace, then pass in a mixed gas of dichlorosilane and silane, the gas flow rate is 4 mL / min, and the tube is heated at a heating rate of 5 °C / min. Heat the temperature of the tube furnace to 1000°C, keep it warm for 2 hours, stop feeding the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com