A device and method for separating two-dimensional nanomaterials by continuous hypergravity diafiltration

A two-dimensional nanomaterial and two-dimensional material technology, applied in the field of continuous hypergravity percolation separation of two-dimensional nanomaterials, can solve the problems of high energy consumption, inability to achieve high-quality large-scale production, and slow separation rate, etc., to achieve The effects of large pore void ratio, small liquid flow resistance, and wide pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

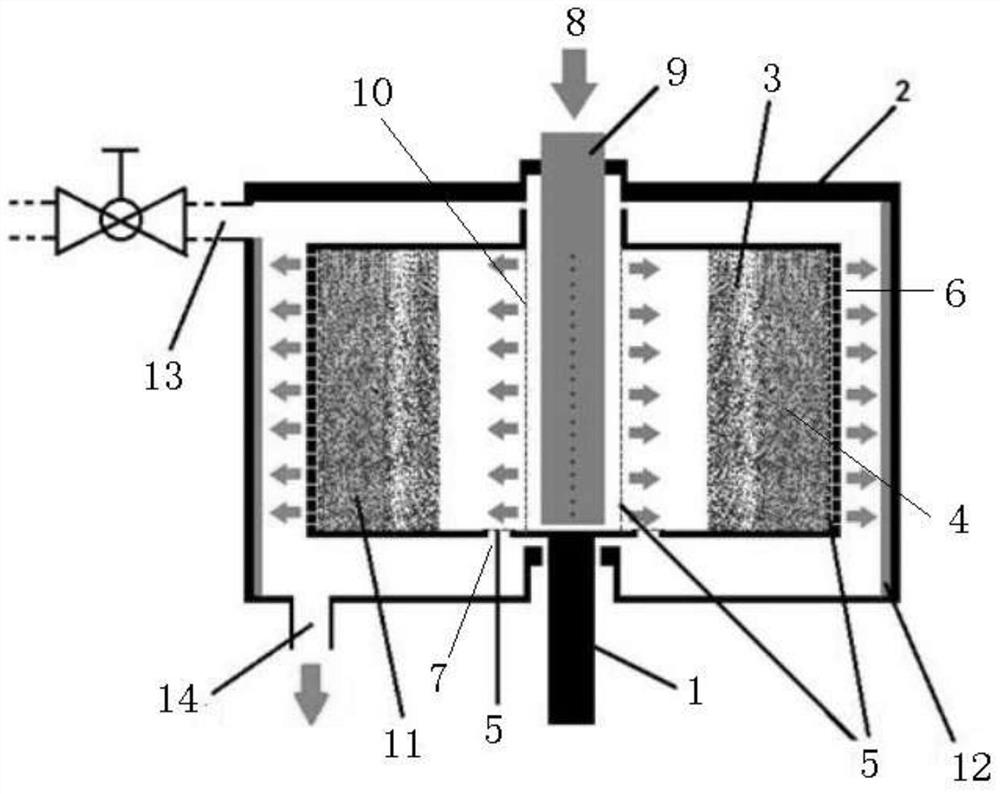

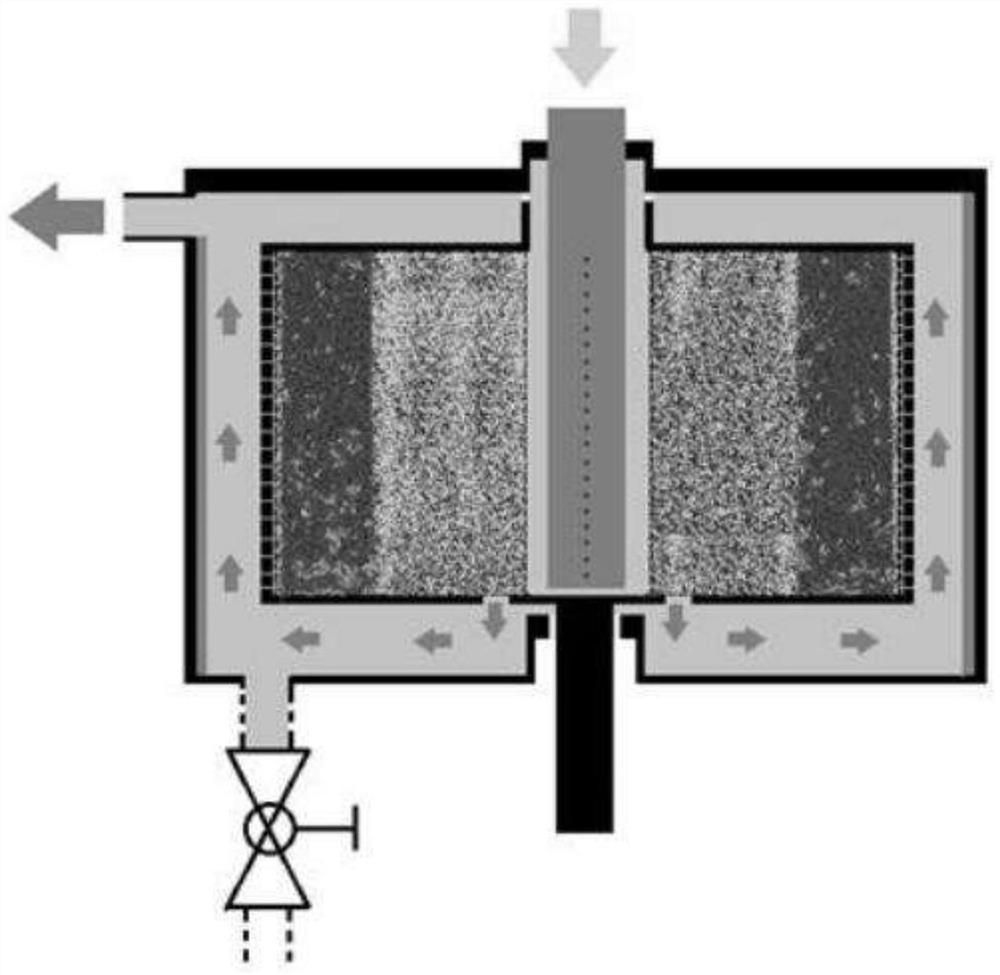

[0037] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

[0038] In the present invention, unless otherwise specified, all equipment and raw materials can be purchased from the market or commonly used in this industry. The methods in the following examples, unless otherwise specified, are conventional methods in this field.

[0039] The process of exfoliating and preparing few-layer graphene materials is illustrated as a specific example. Isopropanol aqueous solution (English abbreviation: IPA) is used as the exfoliating agent. The specific gravity of the solution is 0.95 to 0.96 g / mL. .

[0040] The specific operation steps are as follows: the graphite concentration in the graphite slurry flowing out of the continuous stripping device is 0.8%, the concentration of the few-layer graphene contained in it fluctuates between 0.01 mg / mL and 0.02 mg / mL, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com