Preparation method of germanium-free iwr zeolite molecular sieve

A zeolite molecular sieve and heteroatom technology, which is applied in molecular sieve catalysts, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve the problems of poor structural stability of IWR zeolite molecular sieve, large amount of use, high cost of template agents, etc. The effect of promotion, saving synthesis cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 0.25g boric acid in 2.693g 45wt% choline hydroxide aqueous solution, add 3g Ludox (HS-40, 40%) and stir evenly, finally add 1g 37% NH 4 F aqueous solution. The vessel was stirred open overnight to evaporate some of the water until the reaction mixture reached the final molar composition.

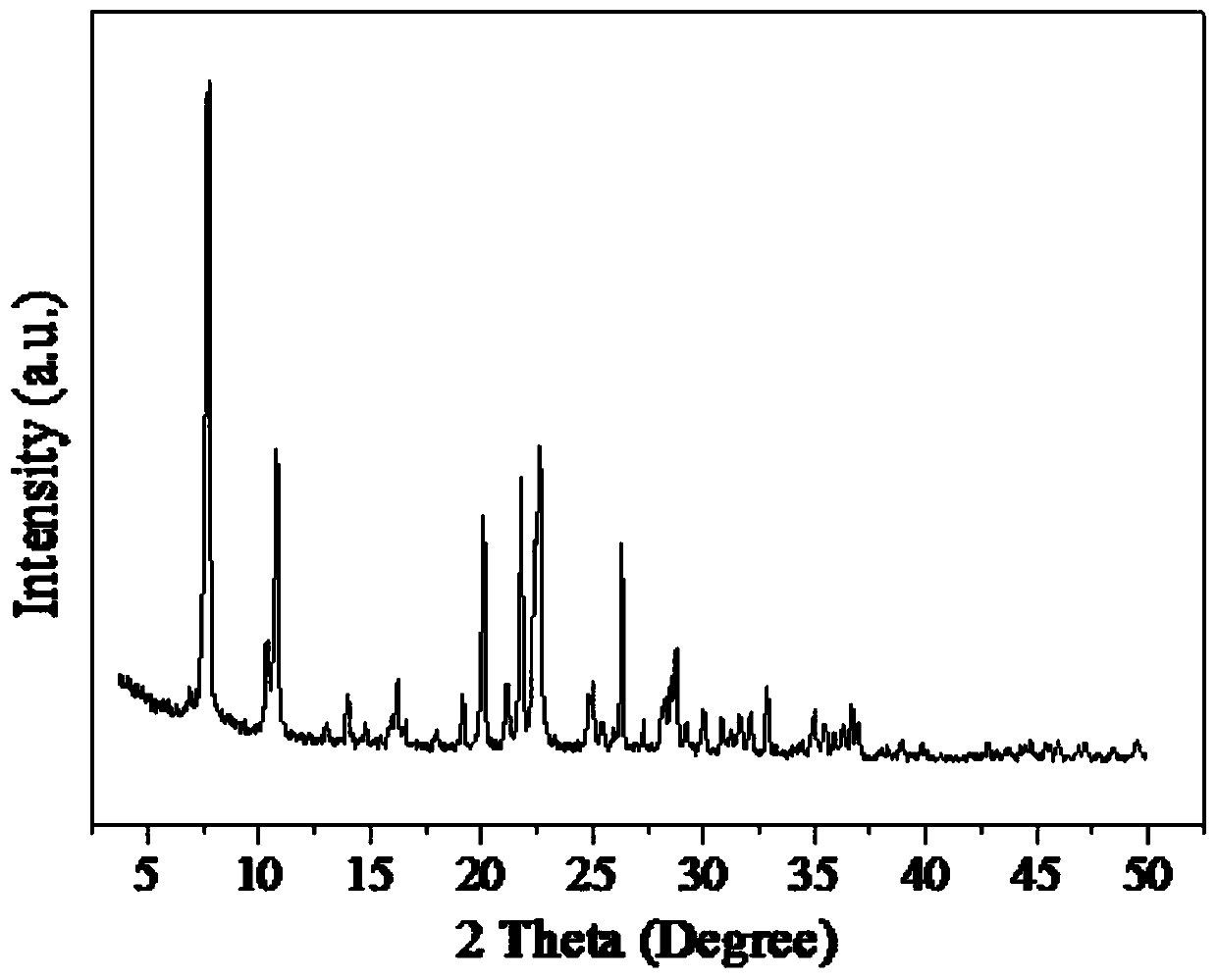

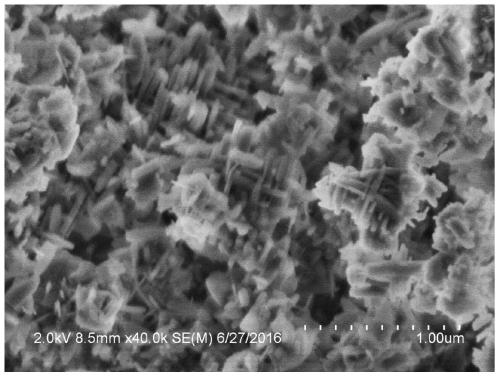

[0031] The above mixture was put into a crystallization kettle with a polytetrafluoroethylene liner, and placed in an oven at 170°C for crystallization for 168 hours. After the reaction, the solid was filtered, washed with distilled water, and dried at 100° C. to obtain a solid powder. The raw powder solid is placed in a muffle furnace and roasted at a temperature of 550° C. for 5 hours to obtain the final product. After calcination, the sample shows a stable IWR structure, and the XRD pattern is as follows figure 1 As shown, the SEM photos are as figure 2 shown.

[0032] The stability of the IWR zeolite molecular sieve was analyzed according to the following method: so...

Embodiment 2

[0034] Dissolve 0.6g boric acid in 2.693g 45wt% choline hydroxide aqueous solution, add 3g Ludox (HS-40, 40%) and stir evenly, finally add 1g 37% NH 4 F aqueous solution. The vessel was stirred open overnight to evaporate some of the water until the reaction mixture reached the final molar composition.

[0035] The above mixture was put into a crystallization kettle with a polytetrafluoroethylene liner, and placed in an oven at 170°C for crystallization for 120 hours. The solid obtained after the reaction is filtered, washed, dried and calcined is IWR molecular sieve.

Embodiment 3

[0037] Dissolve 0.9g boric acid in 2.693g 45wt% choline hydroxide aqueous solution, add 4.16g tetraethyl orthosilicate (TEOS) and add 1.2g 37% NH 4 F aqueous solution. The vessel was left open and stirred overnight to evaporate the ethanol and some of the water until the reaction mixture reached the final molar composition.

[0038]The above mixture was put into a crystallization kettle with a polytetrafluoroethylene liner, and placed in an oven at 160°C for crystallization for 192 hours. The solid obtained after the reaction is filtered, washed, dried and calcined is IWR molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com