Preparation method of high-purity cerium oxide for compact fluorescent lamps

A cerium oxide, high-purity technology, applied in chemical instruments and methods, rare earth metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of high cost and inability to have purity, and achieve advanced technology and high environmental protection , Adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

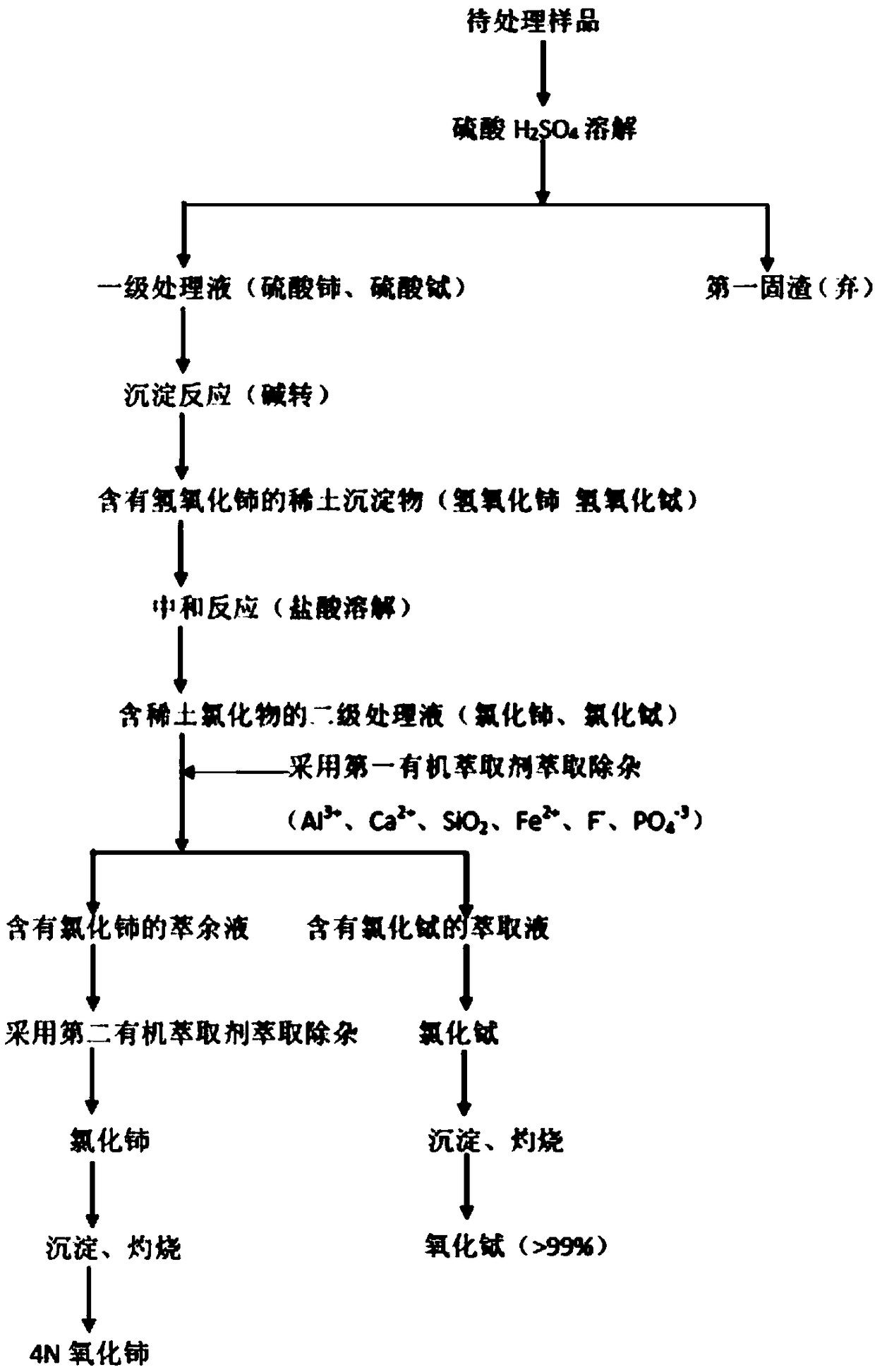

[0017] As described in the background art, the existing preparation methods cannot combine the advantages of high purity and low cost. In order to solve the above technical problems, the application provides a method for preparing high-purity cerium oxide for compact fluorescent lamps, the content of cerium oxide in high-purity cerium oxide is ≥99.99wt%, and the samples to be treated include cerium oxide and terbium oxide, The above preparation method includes: treating the sample to be treated with sulfuric acid to dissolve cerium oxide and terbium oxide to obtain a primary treatment liquid and a first solid residue; subjecting the primary treatment liquid to a precipitation reaction to obtain a rare earth precipitate containing cerium hydroxide The rare earth precipitate is neutralized with hydrochloric acid to obtain a secondary treatment solution containing rare earth chloride; the first organic extractant is used to carry out the first extraction treatment on the second tr...

Embodiment 1

[0036] use as figure 1 The shown process flow prepares high-purity cerium oxide, and the specific operation process is as follows:

[0037] The sample to be treated includes 55% cerium oxide and 35% terbium oxide and impurities.

[0038] The above-mentioned sample to be treated was dissolved with 6 mol / L sulfuric acid to obtain a primary treatment solution, wherein the ratio of the total amount of cerium oxide and terbium oxide to the molar number of sulfuric acid was 1:1.5.

[0039] Using 9 mol / L sodium hydroxide solution to convert the cerium element in the primary treatment solution into cerium hydroxide precipitate to obtain a rare earth precipitate containing cerium hydroxide. The molar ratio of rare earth oxide to sodium hydroxide is 1:1.6. After the reaction is complete, take the supernatant and test it with oxalic acid solution. If there is no precipitation, it indicates that the rare earth elements have completely precipitated.

[0040] 6 mol / L hydrochloric acid wa...

Embodiment 2

[0045] The difference from Example 1 is that the first organic extractant is a mixture of di(2-ethyl-hexyl) phosphate (P204) and kerosene at a weight ratio of 1:1.

[0046] The purity of the prepared cerium oxide product is 99.995wt%, and the yield is 91.7wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com