A kind of rare earth metal catalyst system and method for preparing high cis-conjugated diene polymer

A rare earth metal and catalyst technology, applied in the field of rare earth metal catalysts and the preparation of high cis conjugated diene polymers, can solve the problems of low coupling efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] During the configuration of the catalyst system and the polymerization process, all operations were carried out under the protection of nitrogen.

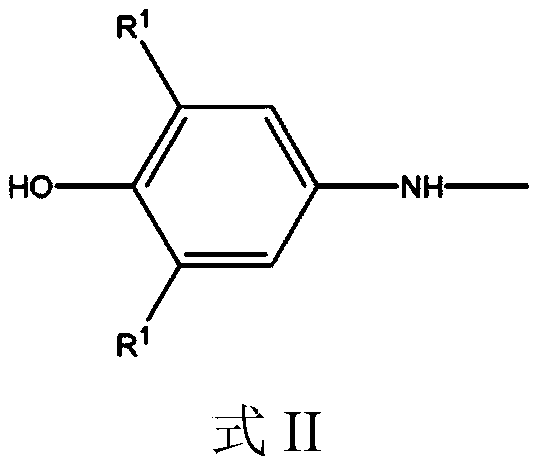

[0056] The rare earth metal catalyst system consists of neodymium 2-ethylhexanoate (A), triisobutylaluminum and diisobutylaluminum hydride (B, the ratio of the two components is 7:1), chloroform and ethyl trichloroacetate (C, the ratio of the two components is 20:1), isooctanoic acid (D), 2,6-di-tert-butyl-4-methylphenol and 3,5-di(1,1-dimethylethyl) -Butyl 4-hydroxyphenylpropionate (E, the ratio of the two components is 100:1), the temperature is 35°C, and the time is 10 hours. The feeding method of each component in the catalyst is B-C-A-D-E, and the molar ratio of each component is A: B:C:D:E=1:18:3.5:2.5:2.5×10 -4 . Add appropriate amount of above-mentioned rare earth metal catalyst to butadiene / hexane solution (monomer concentration is 130g / L), make catalyst component A and butadiene monomer molar ratio be 1.0 * 10 -...

Embodiment 2

[0059] During the configuration of the catalyst system and the polymerization process, all operations were carried out under the protection of nitrogen.

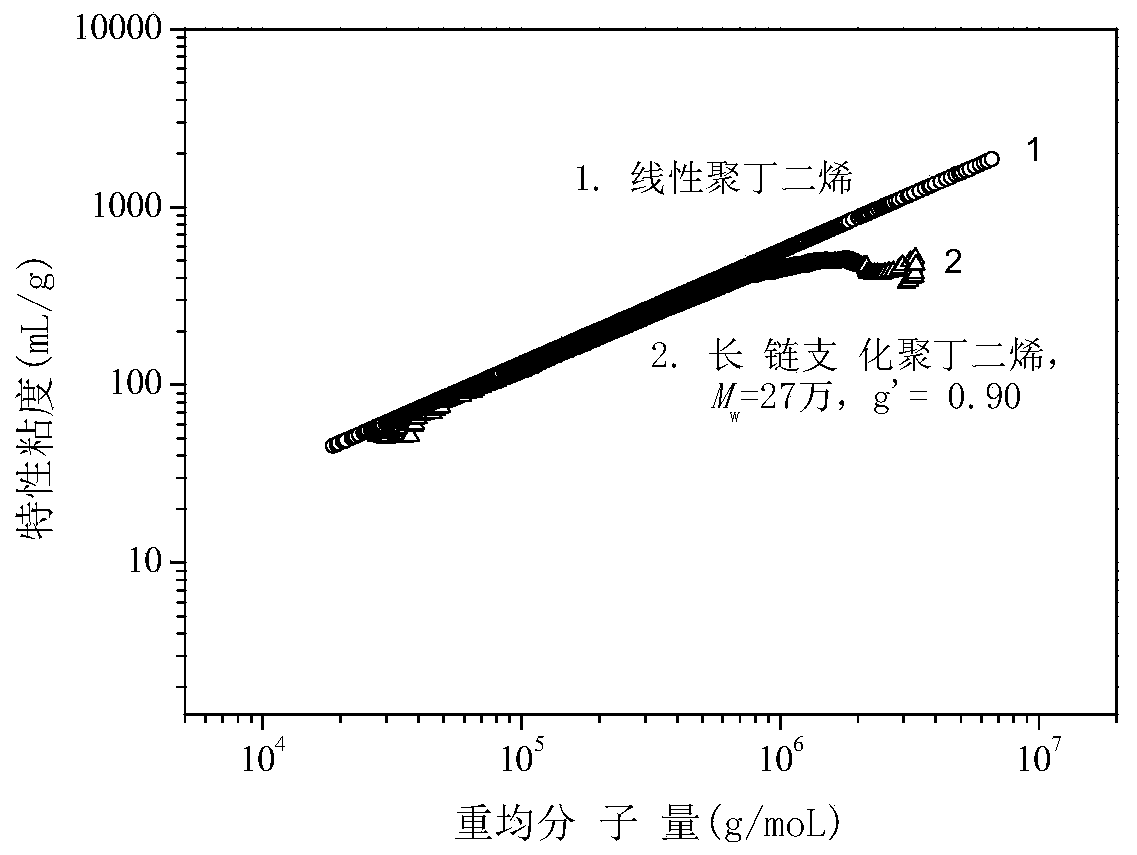

[0060] Catalyst and polymerization process are the same as embodiment 1, and difference is, the feeding mode of each component in the catalyst is B-C-D-A-E, and catalyst component A and butadiene monomer molar ratio are 8.0 * 10 -5 : 1, the polybutadiene product was obtained, and the yield was 32%. M of polybutadiene w 3.4×10 5 g / mol, M w / M n is 3.1, and the cis-1,4 content is 98.6%. The polybutadiene product is a long-chain branched structure polymer, and g' is 0.84.

Embodiment 3

[0062] During the configuration of the catalyst system and the polymerization process, all operations were carried out under the protection of nitrogen.

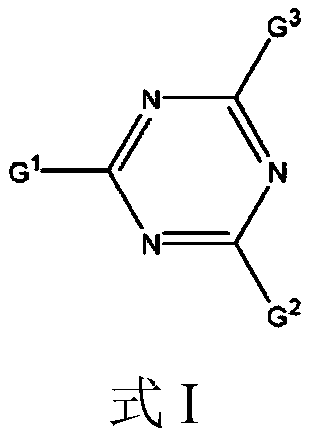

[0063] The catalyst and polymerization process are the same as in Example 1, except that the catalyst component A is neodymium neodecanoate, the ratio of decanoic acid (D) to A is 0.3, and E is 6-(4-hydroxyl-3,5-di-tert-butyl Anilino)-2,4-di-n-octylthiol-1,3,5-triazine and 2,6-di-tert-butyl-4-methylphenol (the ratio of the two components is 58:1), The feeding method of each component in the catalyst is C-B-D-E-A. The polymerization time was 40 minutes, and the polybutadiene product was obtained in a yield of 71%. M of polybutadiene w 3.3×10 5 g / mol, M w / M n is 2.3, and the cis-1,4 content is 98.6%. The polybutadiene product is a long-chain branched structure polymer, and g' is 0.94.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Branching factor | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com