Lithium ion super composite capacitor and vehicle-mounted emergency call system

A composite capacitor and lithium-ion technology, applied in the field of electrochemistry, can solve the problems of graphite particle cracking, pulverization, and graphite layer peeling, and achieve the effects of long service life, large pulse current, and low self-discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

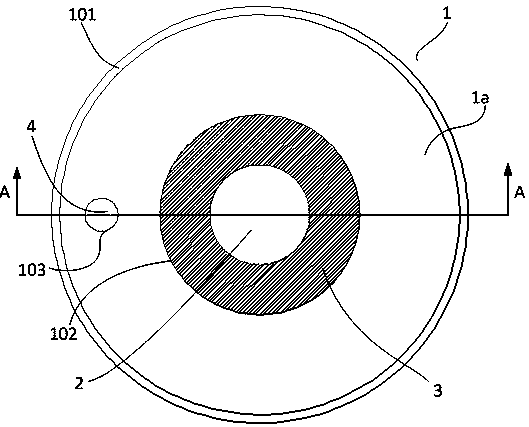

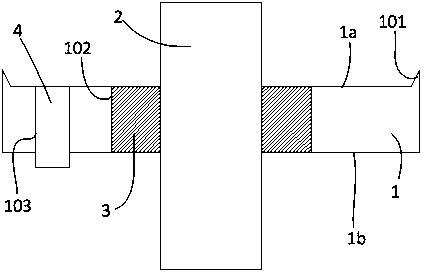

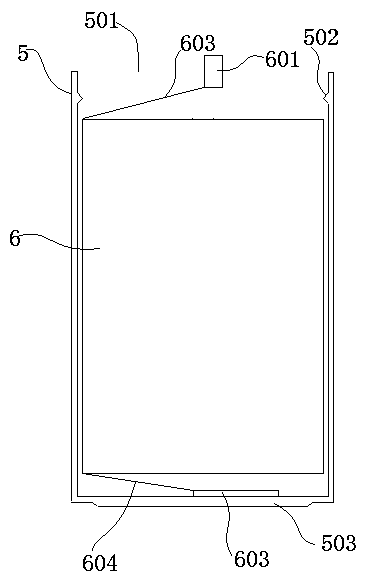

[0042] The lithium-ion super composite capacitor comprises a capacitor cover group, a casing 5 matched with the capacitor cover group, and a capacitor winding core 6 arranged in the casing 5, and the capacitor winding core 6 has a positive pole 603 and a negative pole 604, Connecting the positive pole 603 to the positive pole ear 601 of the positive pole 2, connecting the negative pole 604 to the negative pole ear 602 of the housing 5, and filling the electrolyte in the housing;

[0043] Preferably, the housing 5 is a cylindrical structure with an installation opening 501, the installation opening 501 cooperates with the cover body 1, and the inner wall of the housing 5 near the installation opening 501 is provided with a The limiting protruding ring 502 matched with the cover body 1 .

[0044] Preferably, the positive tab 601 is strip-shaped and made of stainless steel or metal nickel or aluminum-nickel alloy.

[0045] Preferably, a connecting boss 503 is formed on the outsi...

Embodiment 2

[0060] The structure of the lithium-ion super composite capacitor in this embodiment is the same as that in Embodiment 1.

[0061] The positive electrode is coated with LiNiCoAlO with a mass percentage of 40% 2 , LiNi with a mass percentage of 30% 0.8 co 0.1 mn 0.1 o 2 And mass percent is 15% activated carbon, the binder coated on the positive electrode is polyvinylidene fluoride of 4% by mass, and the conductive agent coated on the positive electrode is conductive carbon black of 11% by mass.

[0062] The coating is coated with 15% by mass of natural graphite, 35% by mass of fluorine-doped carbon-coated manganese oxide, 32% by mass of fluorine-doped carbon-coated zinc oxide, and 2% by mass of carboxymethyl fiber element and 10% by mass percent of activated carbon, the binder coated on the negative electrode is 3% by mass percent of styrene-butadiene rubber, and the conductive agent coated by the negative electrode is 3% by mass percent of conductive carbon black.

[0063...

Embodiment 3

[0065] The structure of the lithium-ion super composite capacitor in this embodiment is the same as that in Embodiment 1.

[0066] The positive electrode is coated with LiNi with a mass percentage of 20% 0.8 co 0.1 mn 0.1 o 2 , the mass percentage is 35%LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , LiNi with a mass percentage of 25% 0.6 co 0.2 mn 0.2 o 2 And mass percentage is 10% activated carbon, the binder coated on the positive electrode is 3% polyvinylidene fluoride by mass percentage, and the conductive agent coated on the positive electrode is 7% conductive carbon black.

[0067] The negative electrode is coated with 30% by mass of lithium titanate, 50% by mass of fluorine-doped carbon-coated manganese oxide, 2.5% by mass of carboxymethyl cellulose, and 12% by mass of activated carbon. The coated binder is 3% by mass of styrene-butadiene rubber, and the conductive agent coated on the negative electrode is 2.5% by mass of conductive carbon black.

[0068] The electrolyte in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com