Magnetic nano material for magnetic solid phase extraction and preparation method thereof

A technology of magnetic nanometer and nanometer microspheres, which can be used in material separation, material analysis, material inspection products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

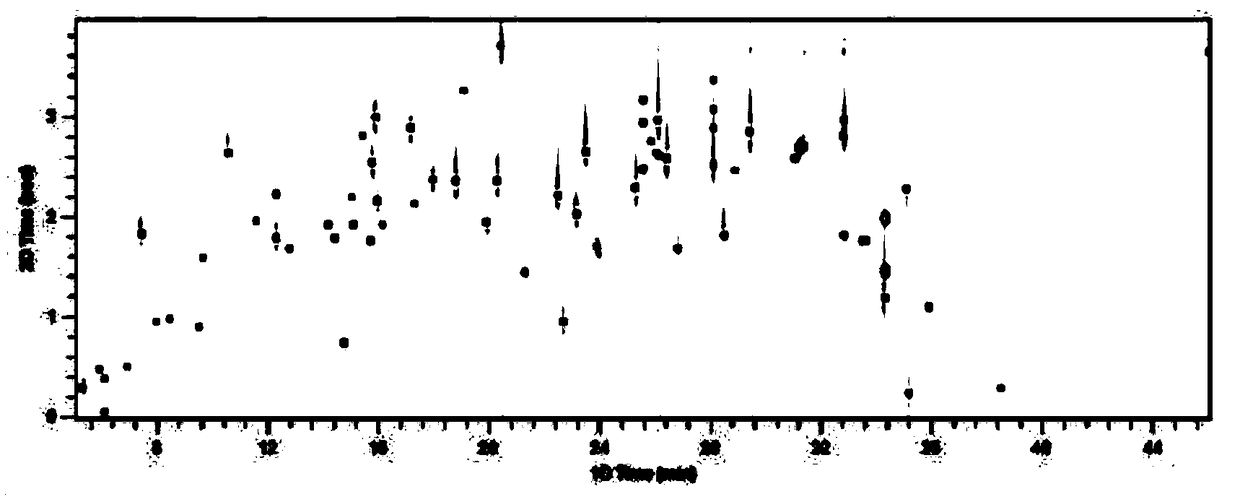

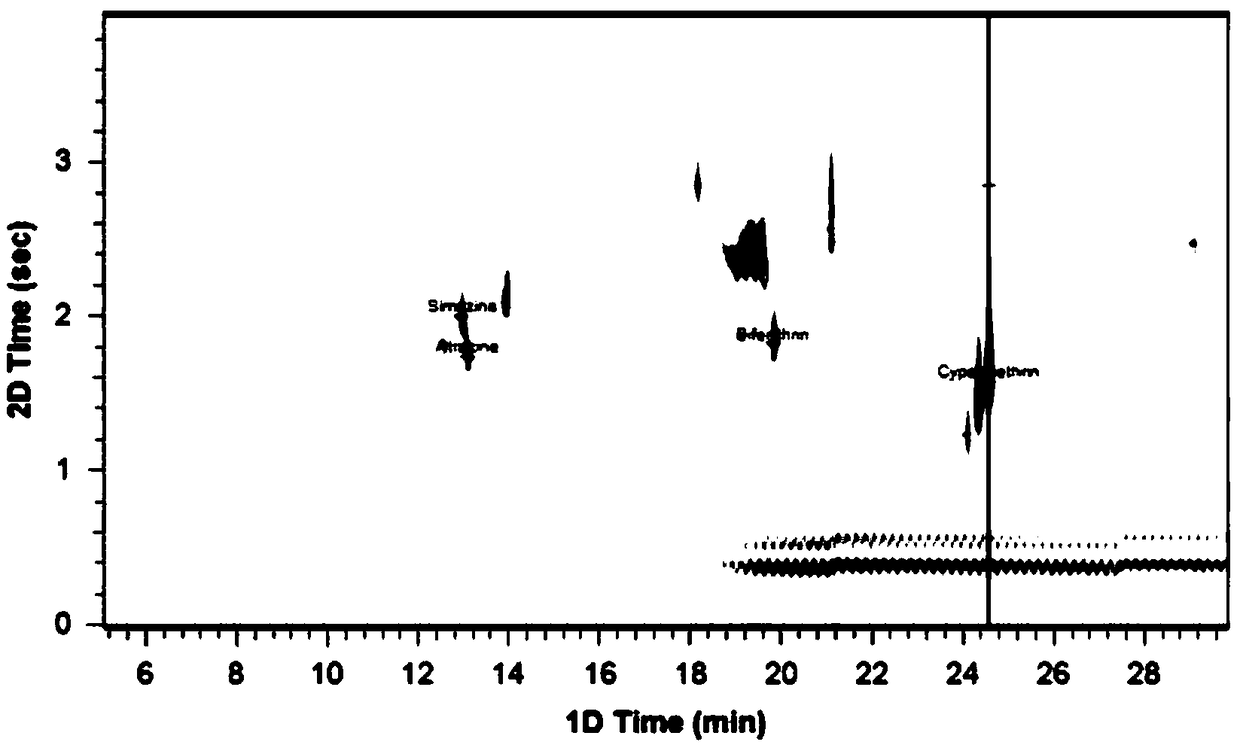

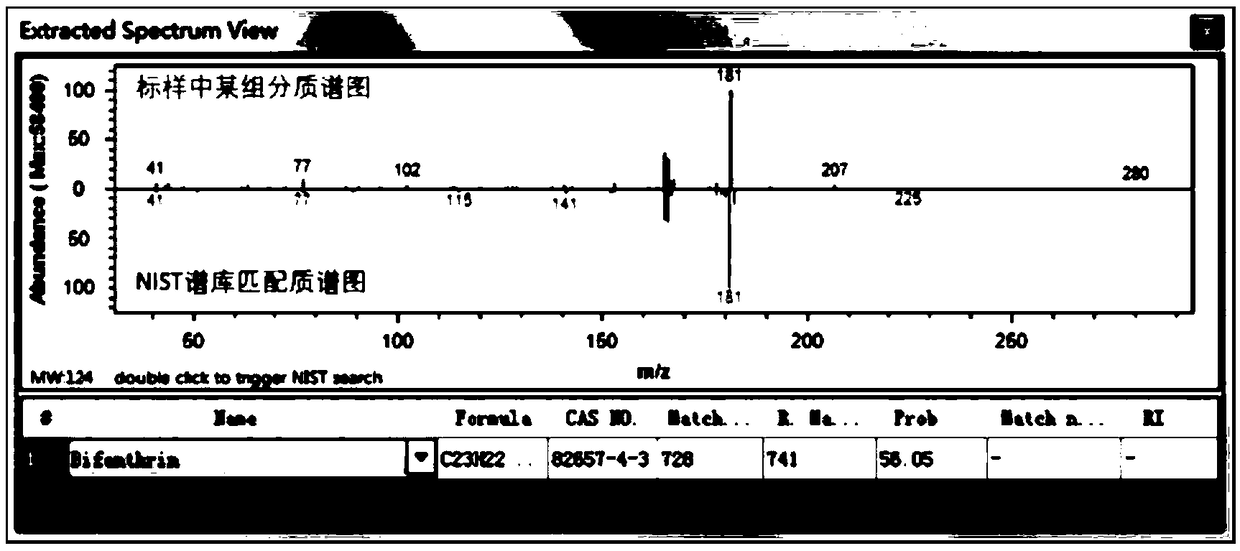

Image

Examples

Embodiment 1

[0089] Utilize magnetic solid-phase extraction technique to the detection method of fruit, vegetable pesticide residue, comprise the following steps:

[0090] (1) Homogenize 100g of corn kernels with a homogenizer at 9500 rpm for 1 minute to obtain a slurry; take 5g of the slurry in a 50mL centrifuge tube with a stopper, then add 20mL of deionized water and 2mL of acetonitrile, and dissolve at 1800 rpm Shake for 2 minutes;

[0091] (2) Add 50 mg of magnetic nanomaterials to the centrifuge tube with stopper in step (1), and continue to shake at 1800 rpm for 4 minutes;

[0092] (3) The magnet is placed on the side wall of the centrifuge tube, the magnetic nanomaterials fully absorb the pesticides in the agricultural products, the magnetic magnetic nanomaterials are adsorbed on the side wall close to the magnet, and the mixed solution of agricultural products, acetonitrile and water is discarded, Wash the magnetic nanomaterials 3 times with 2 mL deionized water each time, and di...

Embodiment 2

[0130] Substantially the same as Example 1, the difference is only that the preparation method of the magnetic nanomaterial is:

[0131] S1 with 1.35g FeCl 3 ·6H 2 O and 75mL of ethylene glycol were mixed, stirred at 260 rpm for 0.5 hour under the action of a magnetic stirrer, then added 3.6g of sodium acetate, and continued to stir for 1 hour at 260 rpm; continued to add 2.2g of ethylenediamine, at 260 The mixture was stirred at rpm for 15 minutes to obtain a mixed solution; the mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave with a capacity of 200 mL, and heated and reacted at 200 °C for 12 hours; the reaction product was separated and collected under the action of an external magnetic field, And wash with anhydrous ethanol 60 times the weight of the reaction product, and dry in vacuum at 50°C and a vacuum of 0.07MPa for 8 hours to obtain a black solid Fe 3 o 4 nanospheres;

[0132] S2 will 50mg Fe 3 o 4 The nano-microspheres...

Embodiment 3

[0139] Substantially the same as Example 1, the difference is only that the preparation method of the magnetic nanomaterial:

[0140] S1 with 1.35g FeCl 3 ·6H 2 O and 75mL of ethylene glycol were mixed, stirred at 260 rpm for 0.5 hour under the action of a magnetic stirrer, then added 3.6g of sodium acetate, and continued to stir for 1 hour at 260 rpm; continued to add 2.2g of ethylenediamine, at 260 The mixture was stirred at rpm for 15 minutes to obtain a mixed solution; the mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave with a capacity of 200 mL, and heated and reacted at 200 °C for 12 hours; the reaction product was separated and collected under the action of an external magnetic field, And wash with anhydrous ethanol 60 times the weight of the reaction product, and dry in vacuum at 50°C and a vacuum of 0.07MPa for 8 hours to obtain a black solid Fe 3 o 4 nanospheres;

[0141] S2 will 50mg Fe 3 o 4 The nano-microspheres we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com